X-ray examination method and X-ray examination apparatus

A technology of inspection device and inspection method, applied in X-ray tubes, material analysis using radiation, electronic circuit testing, etc., can solve the problems of increased moving parts, low efficiency, and difficulty in moving, etc., to achieve the effect of high-speed inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the following description, the same reference numerals are assigned to the same elements. Their names and functions are also the same. Therefore, detailed descriptions of them are not repeated.

[0048] (1. Structure of the present invention)

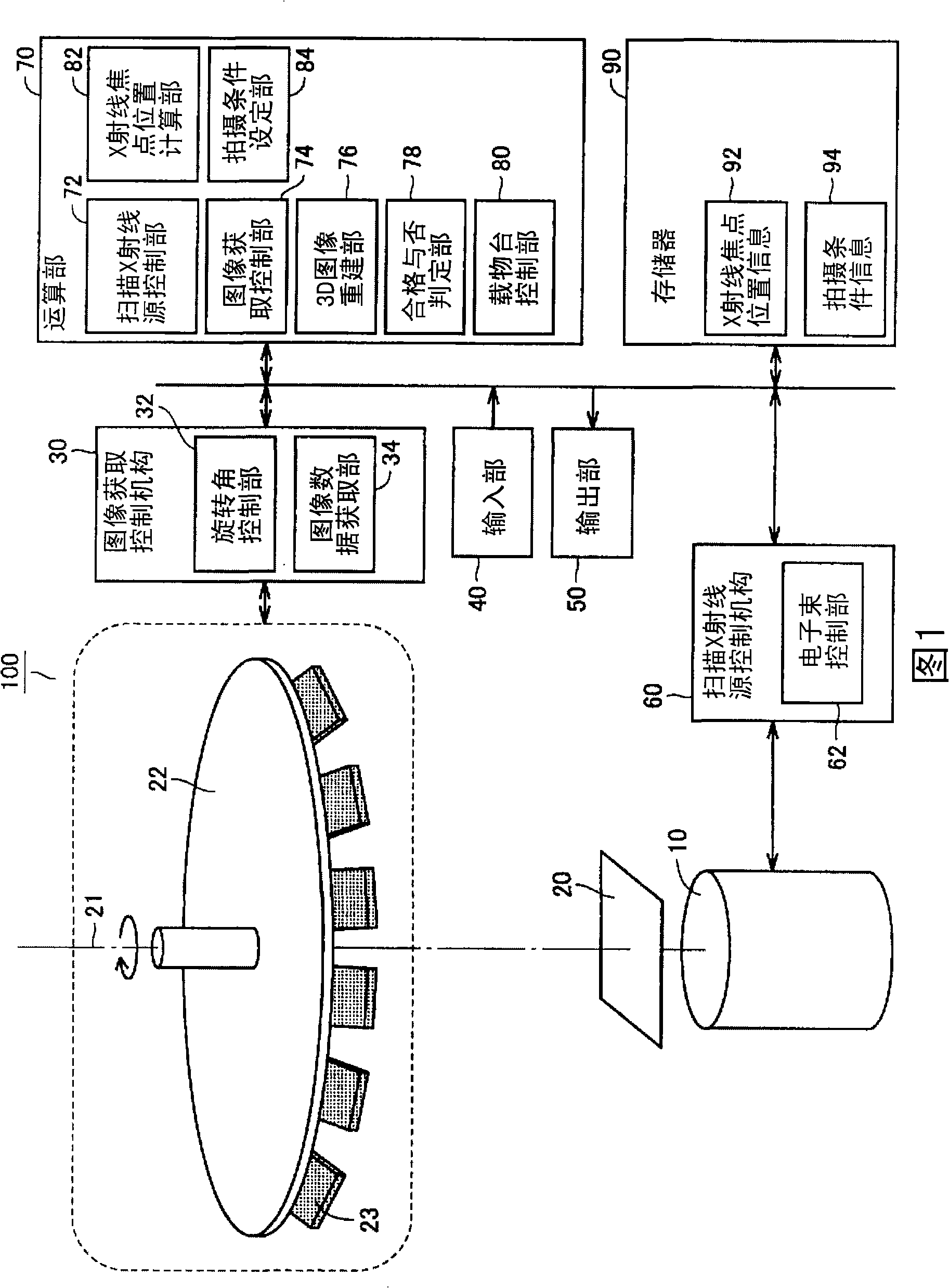

[0049] FIG. 1 is a schematic block diagram of an X-ray inspection apparatus 100 of the present invention.

[0050] Referring to FIG. 1 , an X-ray inspection apparatus 100 of the present invention will be described. However, unless otherwise stated, the scope of the present invention is not limited only to the structures, dimensions, shapes, other relative arrangements, and the like described below.

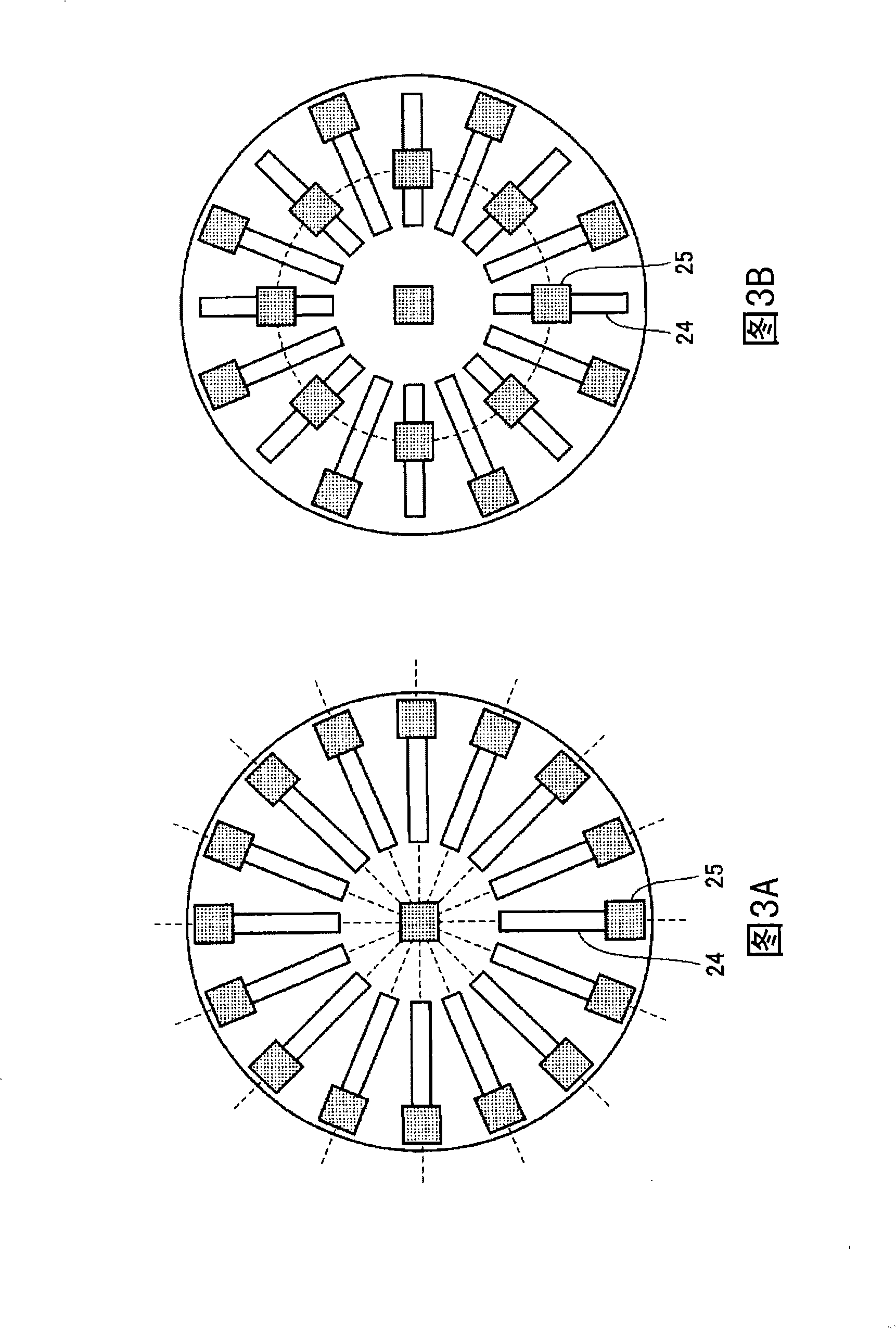

[0051] The X-ray inspection apparatus 100 has a scanning X-ray source 10 for outputting X-rays, and a sensor base 22 that is a rotary table that rotates around a rotation axis 21, and A plurality of X-ray sensors 23 are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com