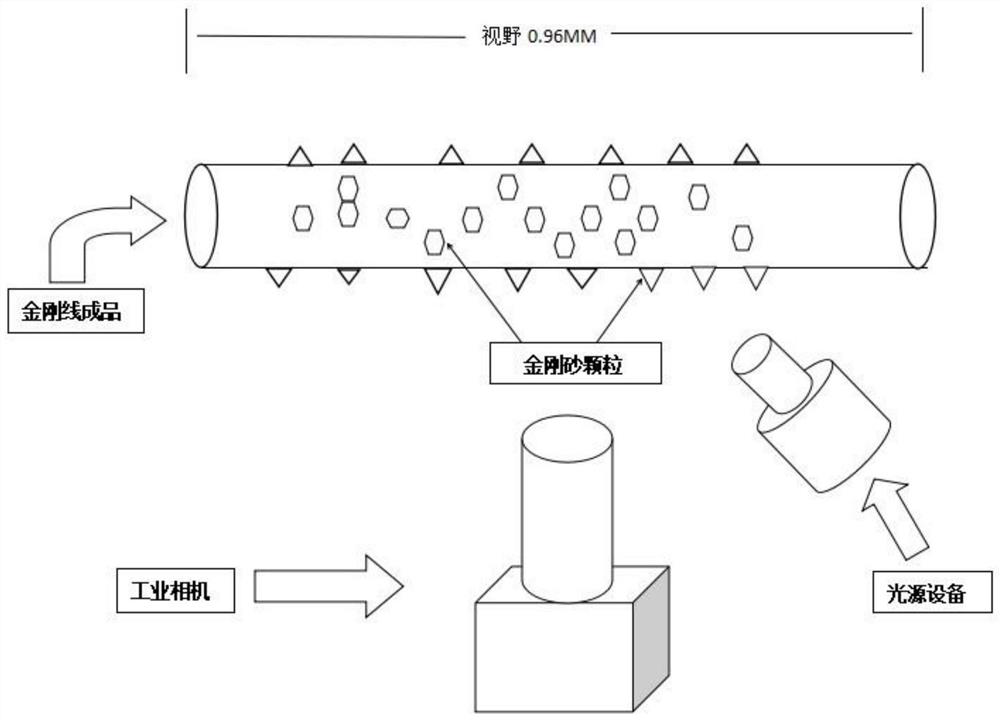

Diamond wire inspection and process control method based on visual system

A technology of process control and vision system, applied in image data processing, instruments, calculations, etc., can solve the problems of difficult control of the detection process and slow detection speed, reduce real-time monitoring and intervention equipment, improve particle accuracy, and ingenious design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0019] A method for applying a vision system to diamond wire inspection and process control, comprising the following steps:

[0020] (1) Image capture: the image capture volume of 300 frames per second is realized by soft trigger mode through industrial cameras;

[0021] (2) Image preprocessing: use Gaussian filtering to clean up the noise in the image while retaining the integrity of the corundum particle outline;

[0022] (3) Image morphology and threshold processing: there are many conjoined particles and impurity particles in the unprocessed image, which will affect the accuracy of particle number detection;

[0023] Call the algorithm to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com