A compound material shell sound reflection board and its making method

A composite material and manufacturing method technology, applied in the direction of sounding equipment, instruments, etc., can solve the problems of many production processes, difficult quality control, low production efficiency, etc. The effect of cost reduction and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

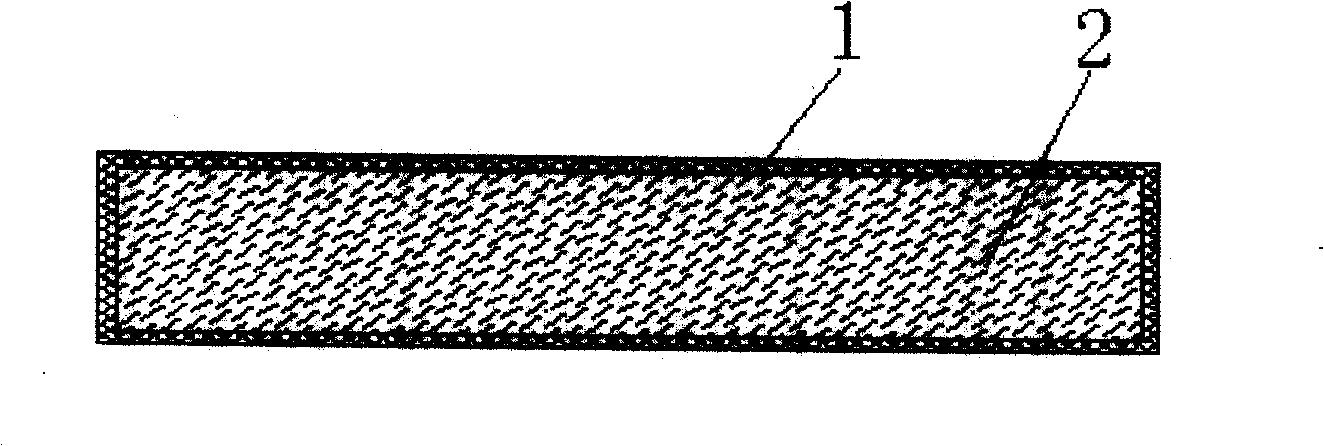

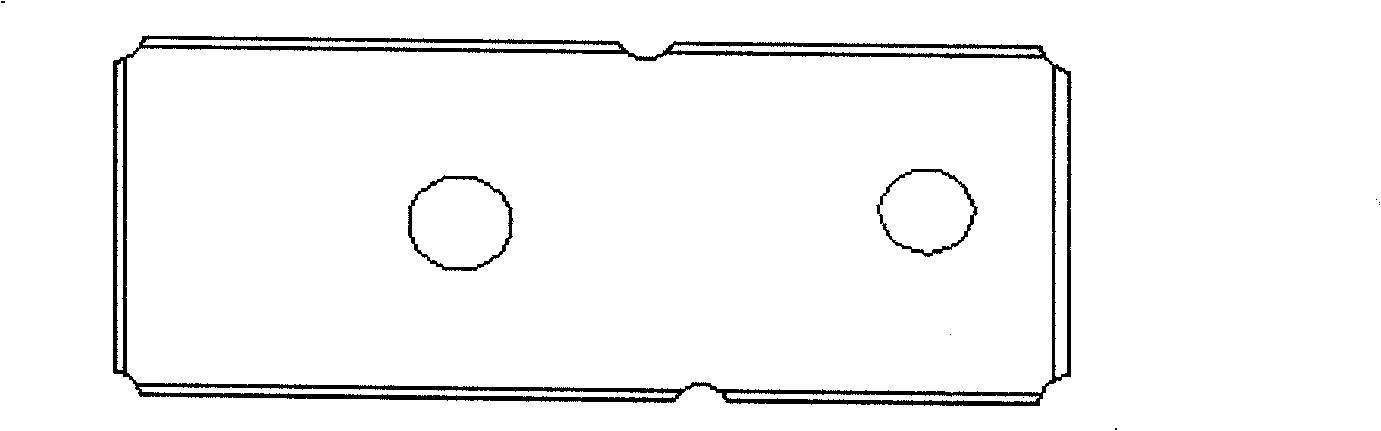

[0023] The density of the core material is 300±10Kg / m 3 The rigid polyurethane foam, the size of the foam body is: the thickness is 358mm×135mm×22mm. The shell is made of 2.5mm thick non-alkali needle felt + 0.2mm thick surface felt as the reinforcement material, using DSM430LV vinyl injection resin as the matrix material, the ratio of reinforcement material and resin is: 40:60, and it is obtained by injection molding with RTM injection molding machine Composite shell anti-acoustic baffle, under the condition of satisfying the acoustic performance, its preparation process is compared with the current rubber shell anti-acoustic baffle technology as shown in Table 1:

[0024] Table 1 Contrast table between existing baffle manufacturing technology and the technology of the present invention

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com