A micro belt aperture shaping wave bundle antenna with serial ladder impedance line feedback

A technology of series feeding and step impedance, which is applied to slot antennas, antennas, antenna arrays, etc., can solve the problems of high processing and manufacturing costs, long feed lines, and large feed line losses, and achieve good impedance matching characteristics, low manufacturing costs, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention is not limited to the scope involved in the embodiments.

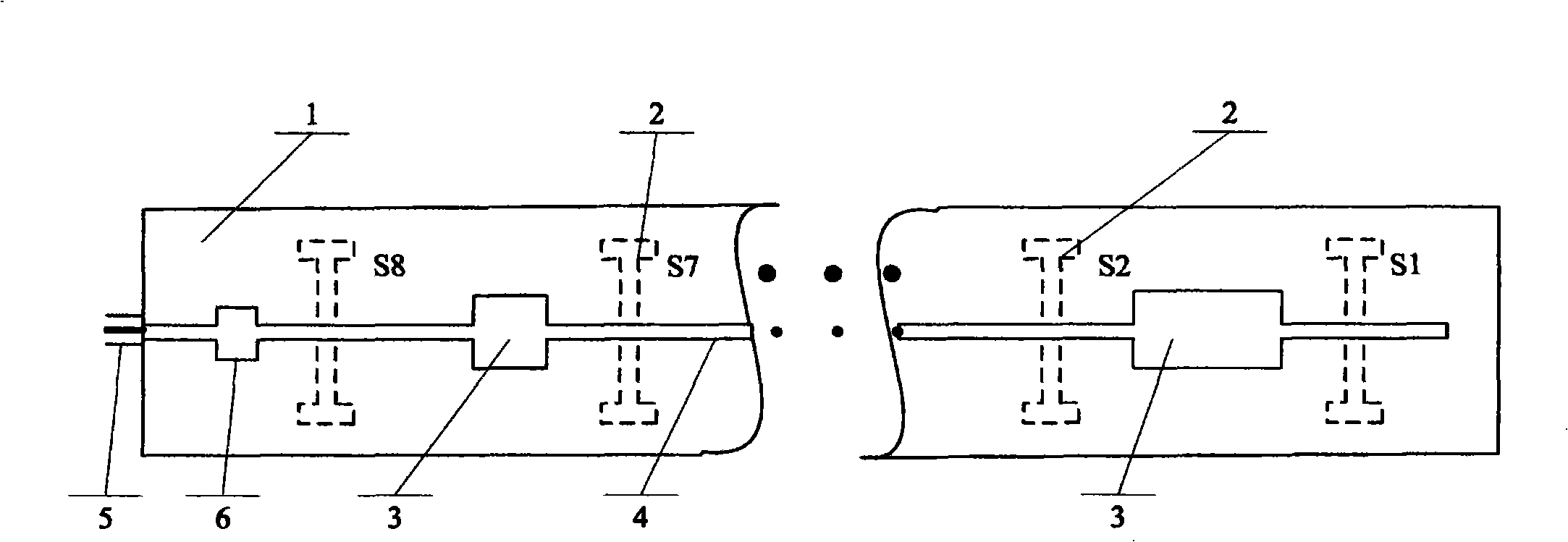

[0018] The antenna structure provided by the present invention is as figure 1 As shown, the antenna is fabricated on a double-sided metal-clad microstrip dielectric board 1 in the form of a printed circuit board. One side of the microstrip dielectric board 1 is a metal-clad ground plane, and more than 3 slot radiation units are etched. 2. The shape of the slot radiation unit 2 can be H-shaped or straight. On the other side of the microstrip plate dielectric plate 1 is a microstrip line formed by series connection of two microstrip lines 3 and 4 with different characteristic impedances. Between every two slot radiation units 2, there is one and only one section of microstrip line 3, and the other microstrip lines are all microstrip lines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com