Two-stroke large diesel engine

A two-stroke, diesel engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as high manufacturing costs and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

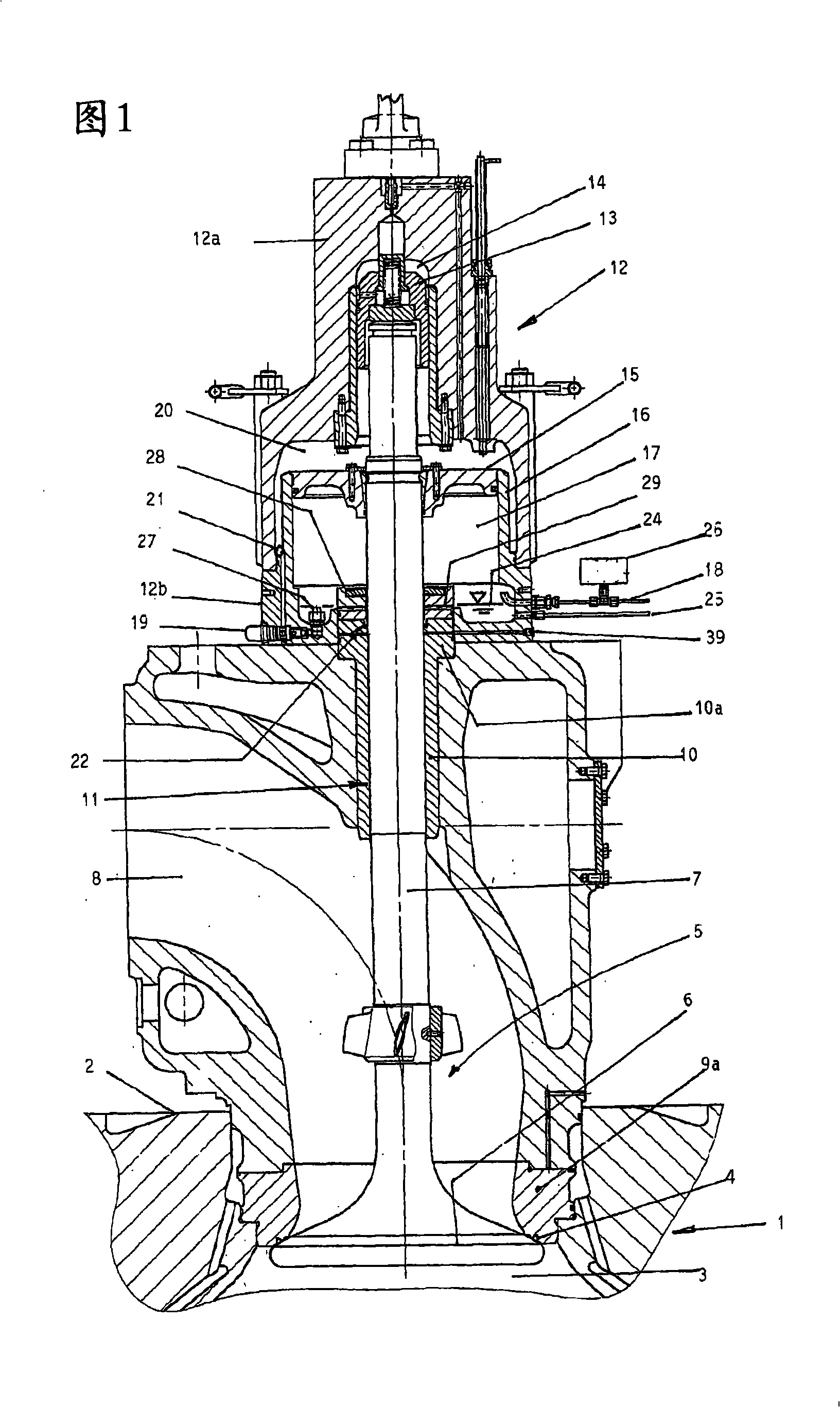

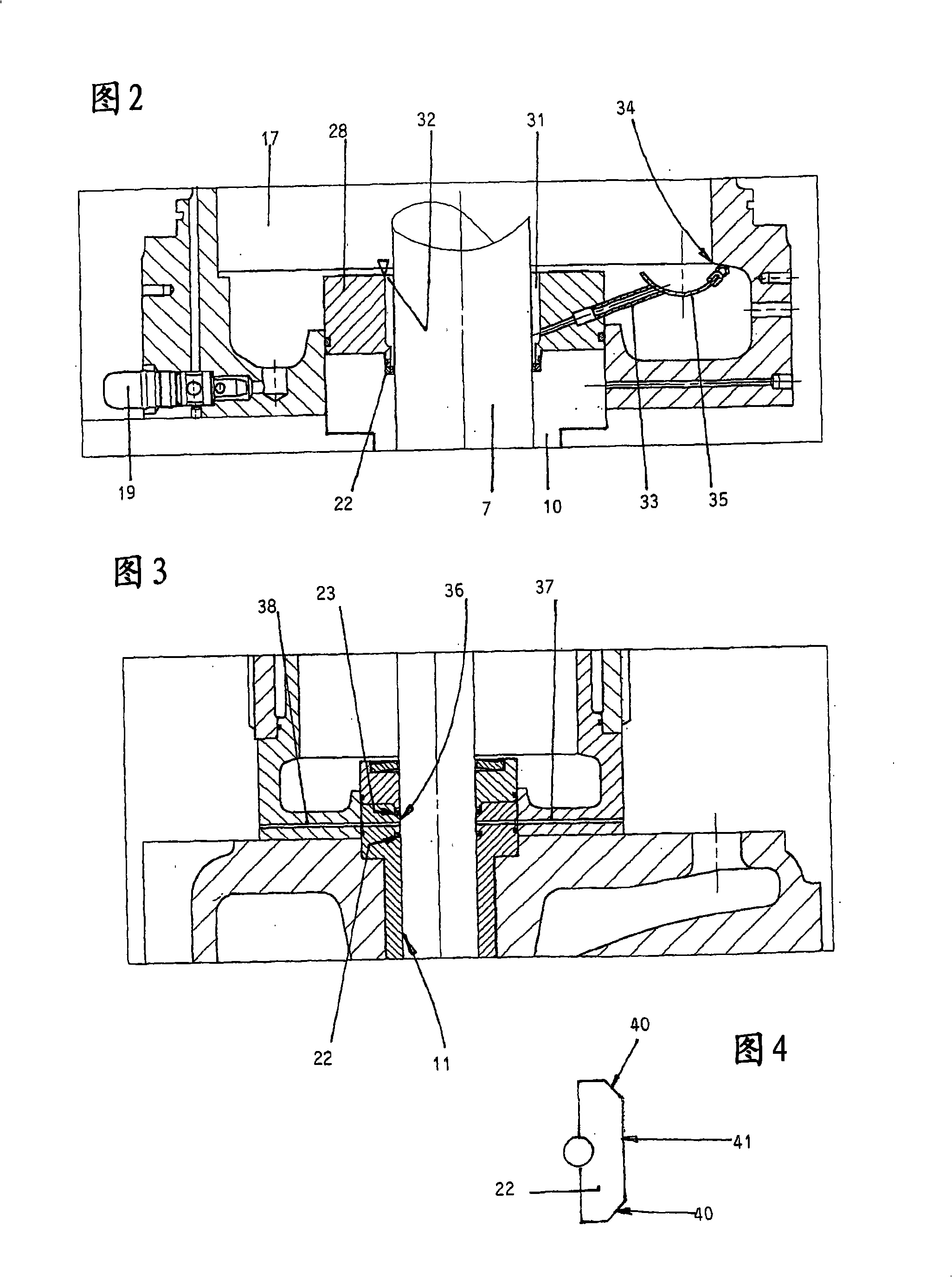

[0022] The main field of application of the invention is the use of two-stroke large diesel engines such as those on marine drives. The structure and principle of action of such devices are known per se.

[0023] Such motors usually have a plurality of cylinders 1 arranged side by side. In FIG. 1 , the upper region of one such cylinder 1 is shown. It comprises a cylinder liner (not shown in FIG. 1 ) and a cylinder head 2 fitted thereon. In the cylinder there is a combustion chamber 3 which is provided with an upper coaxial exhaust port 4 which can be controlled by means of an associated exhaust valve 5 .

[0024] The exhaust valve 5 has a valve disk 6 which interacts with a valve seat arranged in the region of the exhaust opening 4 and which is mounted on the lower end of a spindle-shaped valve stem 7 . Connected to the exhaust port 4 is an exhaust channel 8 which opens towards the combustion chamber 3 when lifted from the seat to which the exhaust valve is assigned, or vic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com