Industrial production sling safety system and security protection method

A technology of safety protection and spreader, applied in the direction of safety device, load hanging element, fluid pressure actuating device, etc., can solve the problems of increasing system failure, gas circuit control failure, lack of concentration, etc., to ensure safety performance, The effect of eliminating misoperation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

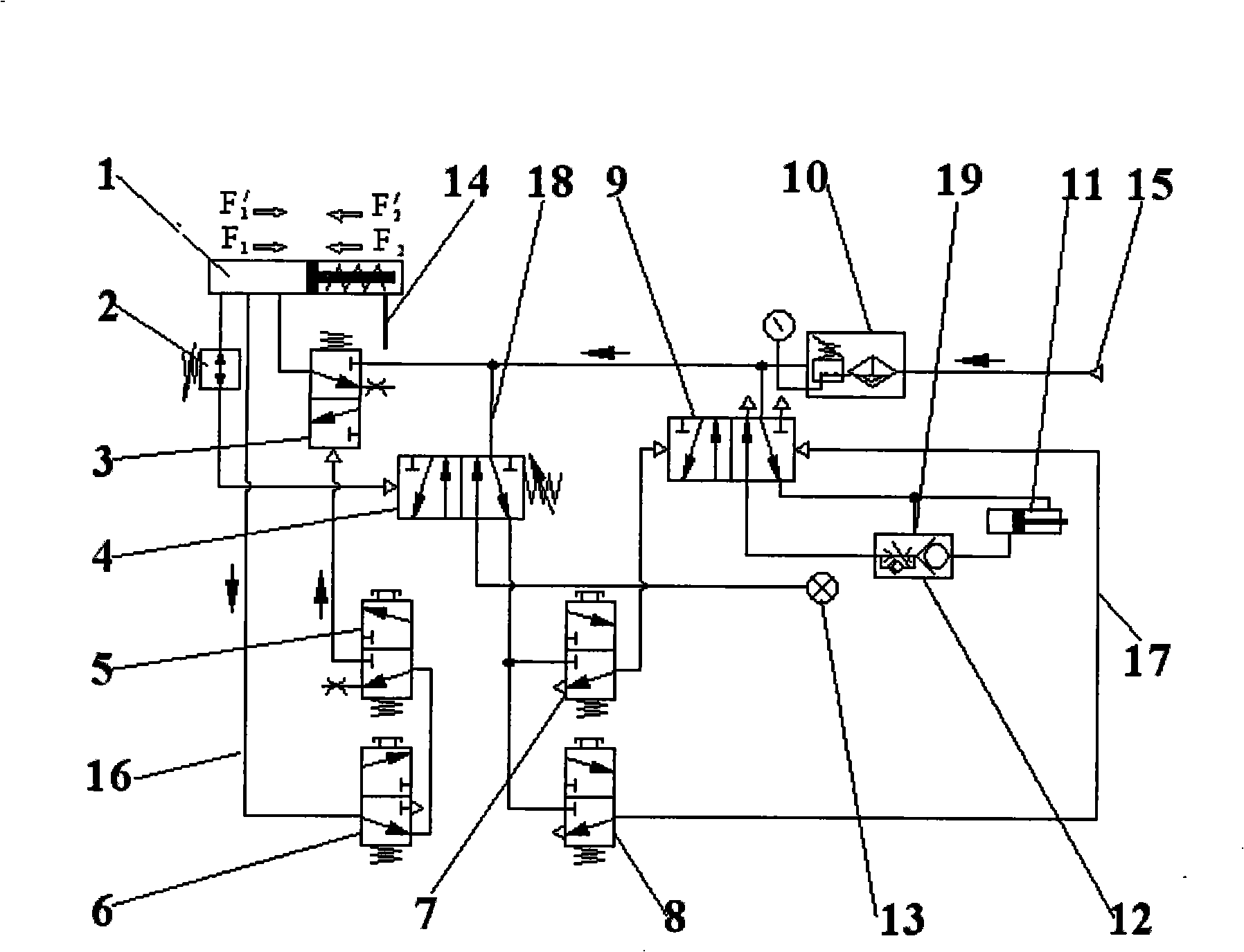

[0042] Embodiment 1. The structure and components of the lifting control air circuit 16 of the spreader:

[0043] In the lifting control air circuit 16 of the spreader described in the above scheme, an up button 5, a down button 6 and an air balancer air intake control valve 3 are set, and the air cavity of the air balancer 1 is controlled by the air intake of the air balancer. When the valve 3 is in the working position, the intake air is from the main air source 15, the air intake control valve 3 of the pneumatic balancer is controlled by the up button 5 to make the air chamber of the pneumatic balancer 1 intake air, and the air balancer 1 is controlled by the down button 6 to make the air flow of the air balancer 1 Cavity throttling exhaust.

[0044] The above-mentioned structure makes the lift of the spreader controlled by the main air source 15 to provide the required power, and the air balancer air intake control valve 3 realizes the on-off of the lift air circuit, so as...

Embodiment 2

[0045] Embodiment 2, the specific structure of the pneumatic balancer intake control valve 3, the up button 5 and the down button 6:

[0046] The pneumatic balancer intake control valve 3 described in Embodiment 1 is a two-position three-way valve whose working position is controlled by pneumatics and the normal position is reset by a spring; Control and normal position are spring-returned two-position three-way valves.

[0047] This embodiment solves the structural forms of the above three pneumatic control elements. Its structure is a two-position three-way valve with spring return, which is simple in structure and good in versatility. In particular, the up button 5 and the down button 6 are actually two pneumatic valves, which are in the form of buttons to directly control the gas circuit, reduce the number of control links, and improve their reliability.

Embodiment 3

[0048] Embodiment 3. The gas path connection relationship of the lifting control gas path 16 of the spreader is as follows:

[0049] The air cavity of the pneumatic balancer 1 described in the above two embodiments, the down button 6, the up button 5, and the working position of the air balancer air intake control valve 3 are sequentially connected through the air circuit;

[0050] When the down button 6 is in the normal position, the air cavity of the pneumatic balancer 1 communicates with the up button 5, and when it is in the working position, the air cavity of the pneumatic balancer 1 communicates with the throttle exhaust port on the down button 6;

[0051] When the up button 5 is in the normal position, the air port connected with the down button 6 is closed, and when it is in the working position, the gas path of the down button 6 is connected with the working position of the air intake control valve 3 of the pneumatic balancer;

[0052] When the pneumatic balancer inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com