Process for the separation of gaseous mix products in chloro-pyridine compounds production

A chloropyridine and separation method technology, applied in fractionation, organic chemistry and other directions, can solve problems such as unfavorable occupational health and safety, low space utilization rate, unfavorable environmental protection, etc., and achieve the advantages of being beneficial to industrialized scale-up production, short residence time, and simplified operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

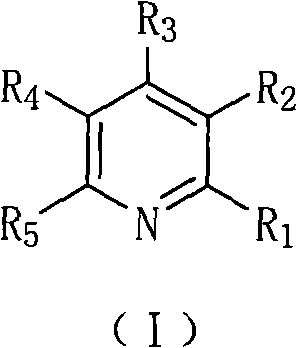

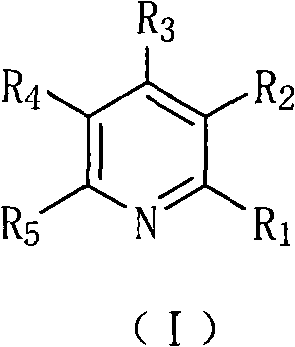

Image

Examples

Embodiment 1

[0016] This example is for pentachloropyridine (bp.283℃~285℃), tetrachloropyridine (bp.251℃~252℃), low chloropyridine (bp.≤235℃, containing trichloropyridine, dichloropyridine, Monochloropyridine, pyridine, etc.) separation, pentachloropyridine content 12.61% in the mixture, tetrachloropyridine content 85.38%, low chloropyridine mixture content 1.82%, other substances 0.19% (all are mass %, the same below).

[0017] In the mixing chamber of the pyridine reactor, put nitrogen at 300°C, pyridine at 120°C, and chlorine at 300°C. After mixing evenly, enter the reactor. The temperature of the reactor is 330°C. The product enters the first rectification through the connecting pipe. The rectification tank and the rectification tower in the unit are separated, the temperature of the connecting pipe is 300°C, the temperature of the rectification tank and the rectification tower is 260°C, and the pentachloropyridine in the product remains in the rectification tank in liquid form . The ...

Embodiment 2

[0019] This example is p-2-chloropyridine (bp.168℃~170℃), 2,6-dichloropyridine (bp.210℃~211℃), 2,3,6-trichloropyridine (bp.232℃) ~233℃), separation of polychloropyridine (bp.≥251℃, including tetrachloropyridine and pentachloropyridine, etc.). The content of polychloropyridine in the mixture is 19.63%, that of triclopyridine is 66.28%, that of dichloropyridine is 11.75%, that of 2-chloropyridine is 1.76%, and that of other substances is 0.58% (both by mass %).

[0020] In the mixing chamber of the pyridine reactor, put nitrogen at 300°C, 2-chloropyridine at 170°C, and chlorine at 300°C. After mixing evenly, enter the reactor. The temperature of the reactor is 350°C. The product enters the first The rectification tank and rectification tower in the rectification unit are separated, the temperature of the connecting pipe is 300°C, the temperature of the rectification tank and the rectification tower is 235°C, and polychloropyridine remains in the rectification tank in liquid form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com