Methanol cracking gas device for automobile and control method thereof

A technology for methanol cracking gas and methanol for vehicles is applied to a methanol cracking gas device for vehicles. The control used in the device is in the field of internal combustion engine fuel supply. Methanol fuel switching problems, etc., to alleviate the tension of petroleum energy, improve fuel economy, and convert flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Through this embodiment, the flow direction of methanol in the exhaust pipe is determined, so that the direction of methanol is opposite to that of engine exhaust gas, and the pyrolysis effect is the best.

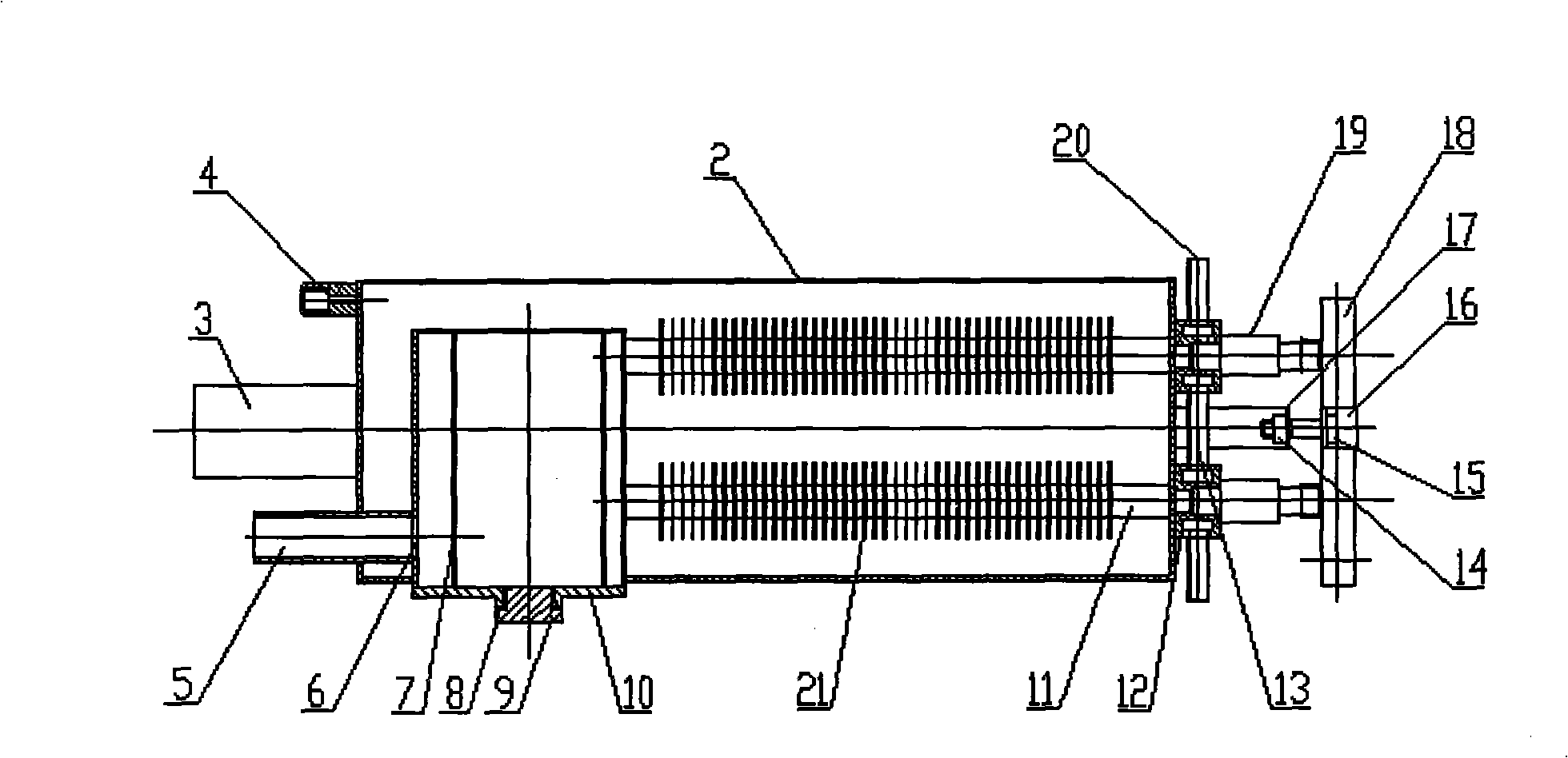

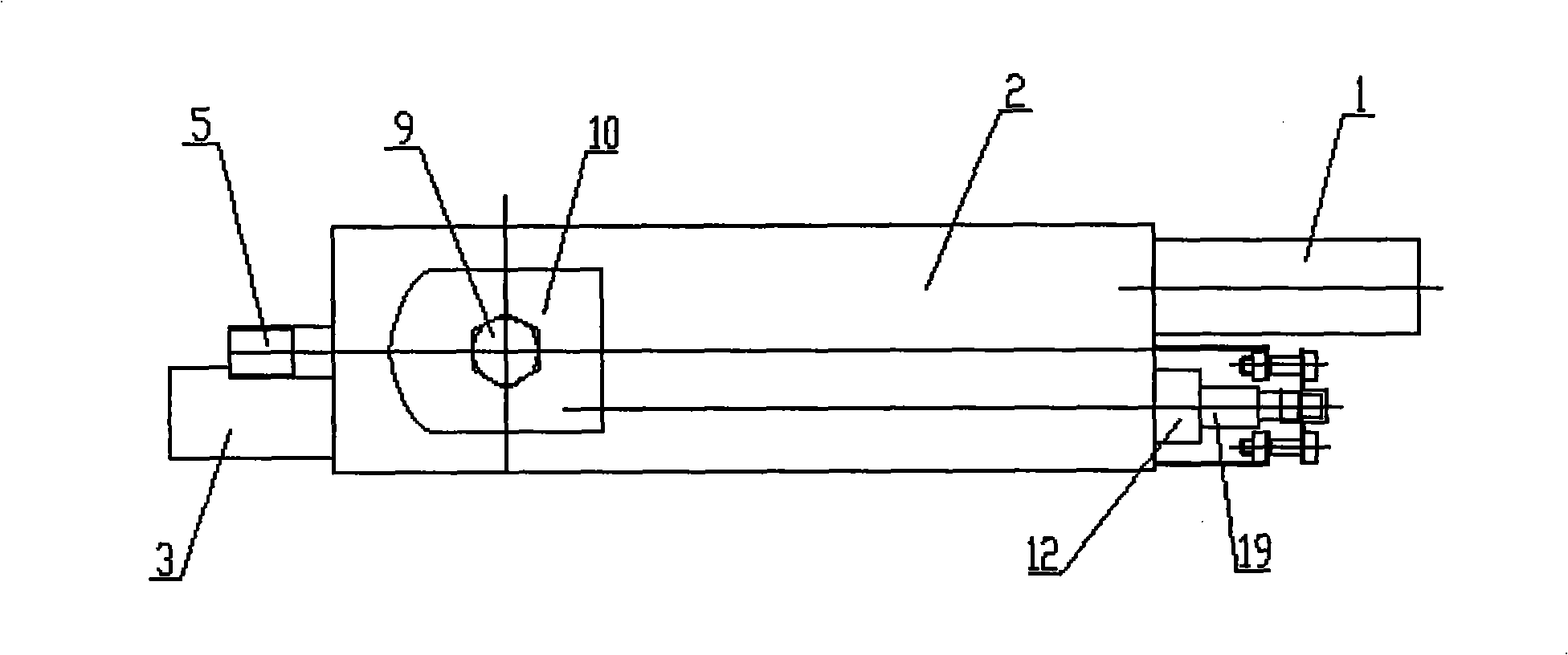

[0037] like figure 1 and figure 2 As shown, the methanol flow pipeline of the methanol cracking gas device is arranged in the cracking gas device shell 2, and its structure is: one end of the rear exhaust pipe 1 is set on the cracking gas device shell 2, and the methanol The nozzle 19 communicates with the catalytic converter outer cylinder 6 through the preheating pipe 11 in the shell 2 of the cracking gas device, and the cracking gas outlet pipe 5 is set on the catalytic converter outer cylinder 6, and the cracking gas outlet pipe 5 is connected from the cracking gas device. One end of the front exhaust pipe 3 is arranged on the shell 2, which leads to the cracked gas device shell 2 and is connected to the fuel injection system of the engine.

[0038]The methan...

Embodiment 2

[0044] The outer surface of the preheating pipe 11 is provided with a plurality of heat transfer fins 21 with good thermal conductivity.

[0045] Through this embodiment, the heat transfer effect of the preheating pipe is improved. The heat transfer fins 21 are integrated with the preheating tube 11 by welding or other techniques.

Embodiment 3

[0047] One end of the front exhaust pipe 3 is set on the cracked gas device shell 2, and a temperature sensor joint 4 is established. A temperature sensor is established on the temperature sensor joint 4, and is connected with the engine electronic control unit through a signal line.

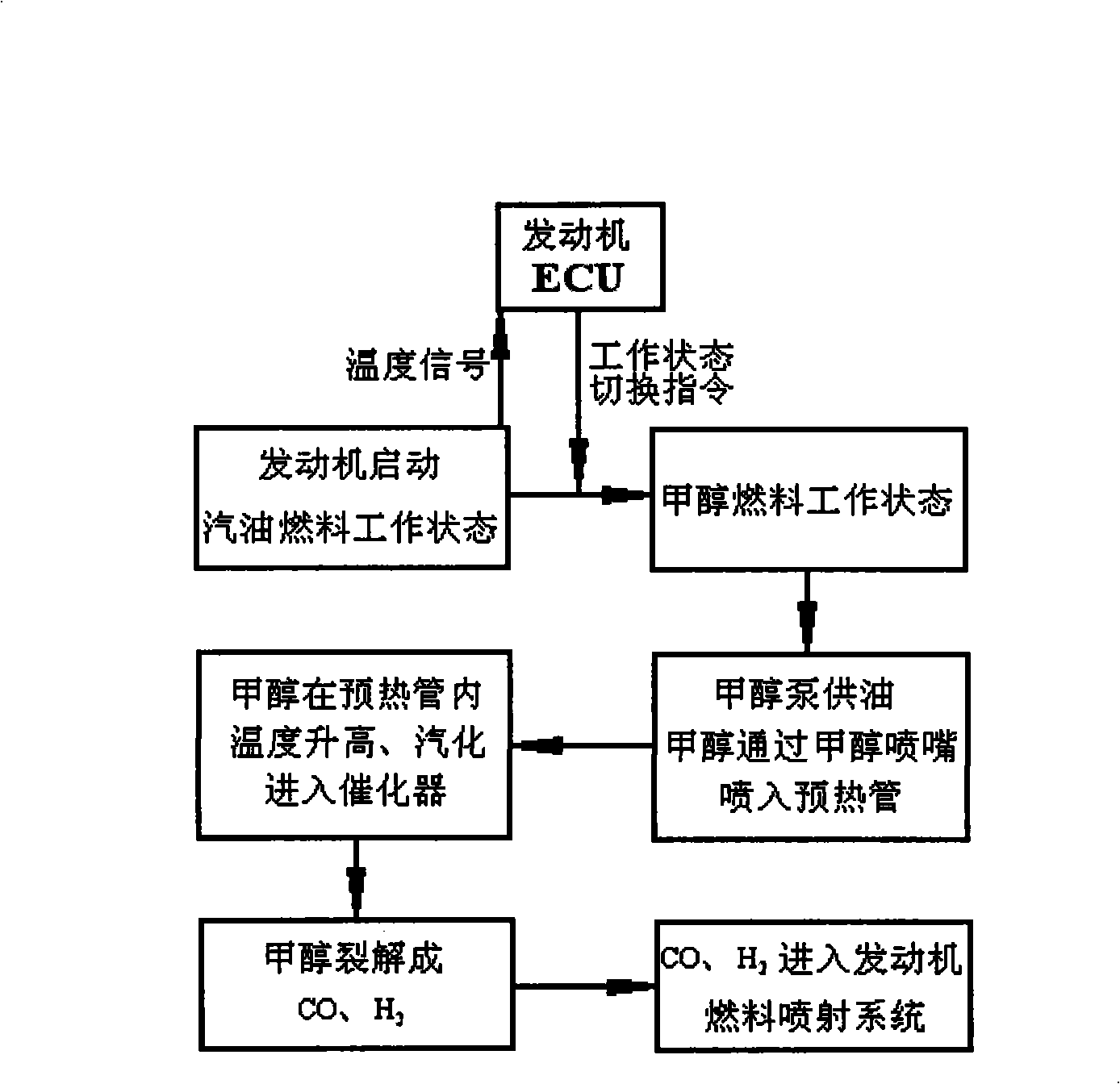

[0048] Through the signal sent by the temperature sensor and the control command of the engine ECU, the system can conveniently and flexibly switch the mode of the working state, and make the engine switch from the gasoline working state to the methanol fuel working state according to the set conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com