Bamboo splints side compression batten type clothes stand and manufacturing method thereof

A production method and technology of bamboo slices, which are applied in the field of hangers, can solve the problems of not being able to occupy a large number of hangers, unfavorable resource safety and environmental protection, and being unable to make fashionable shapes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

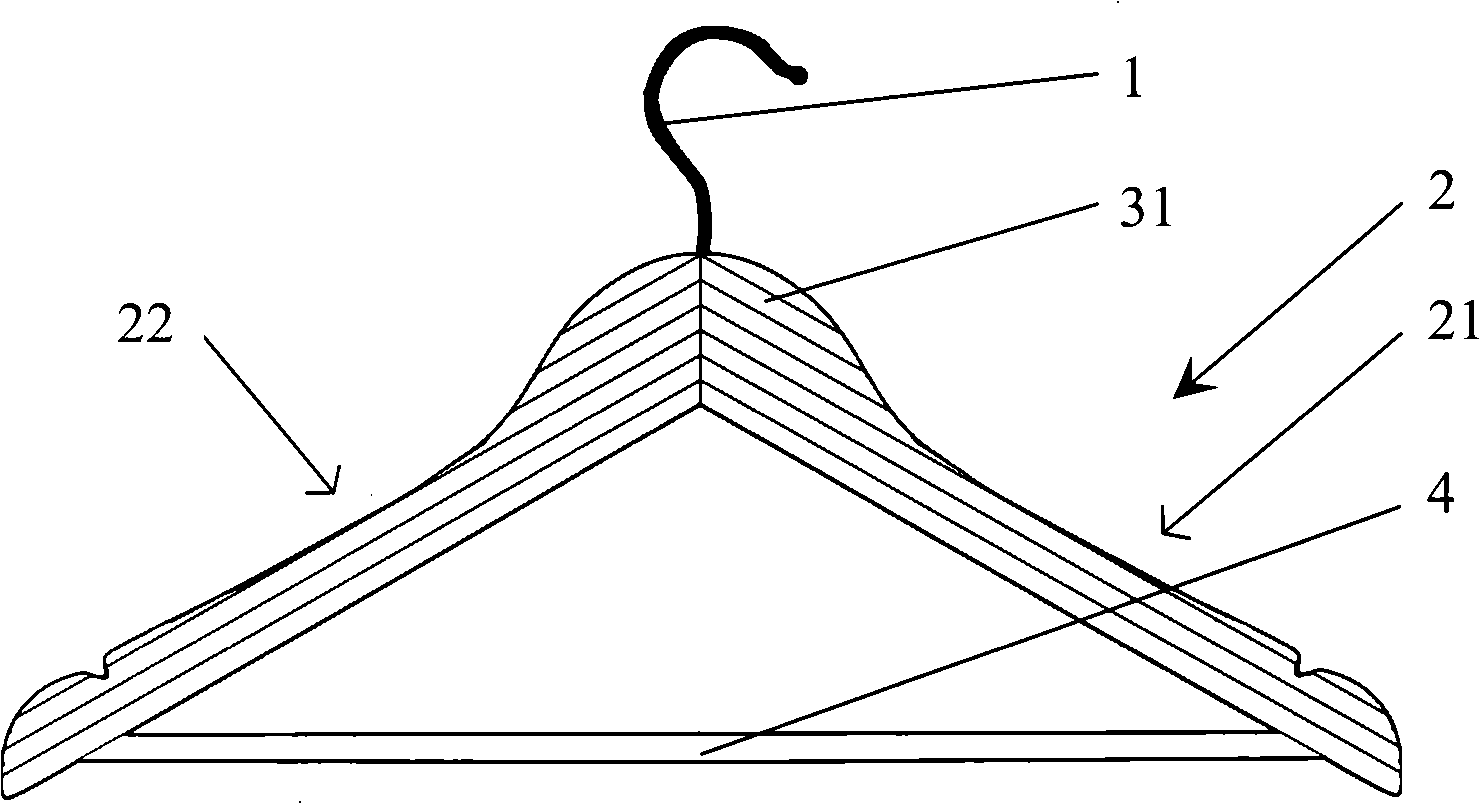

[0030] Such as figure 1 Shown is a schematic diagram of a preferred implementation of the first embodiment of the present invention. In this embodiment, the body 2 is made of side-pressed panels of primary-colored bamboo slices 31 .

[0031] Such as Figure 4 , 7 As shown, the manufacturing method of the above-mentioned primary color bamboo slice 31 side-pressed jigsaw puzzle type clothes hanger comprises the following steps: the original bamboo is cut into bamboo blanks of different specifications by different cutting tools according to needs, and then the bamboo green and green bamboo on the bamboo blanks are removed. Bamboo sacs, after chemical antiseptic treatment, are dried in a drying room for 24 hours to 48 hours to become 31 pieces of primary color bamboo slices, and then glued on the side planes of bamboo slices, arranged into plates (square materials), and arranged Align the bamboo green side with the bamboo green side, and align the bamboo yellow side with the bam...

no. 2 example

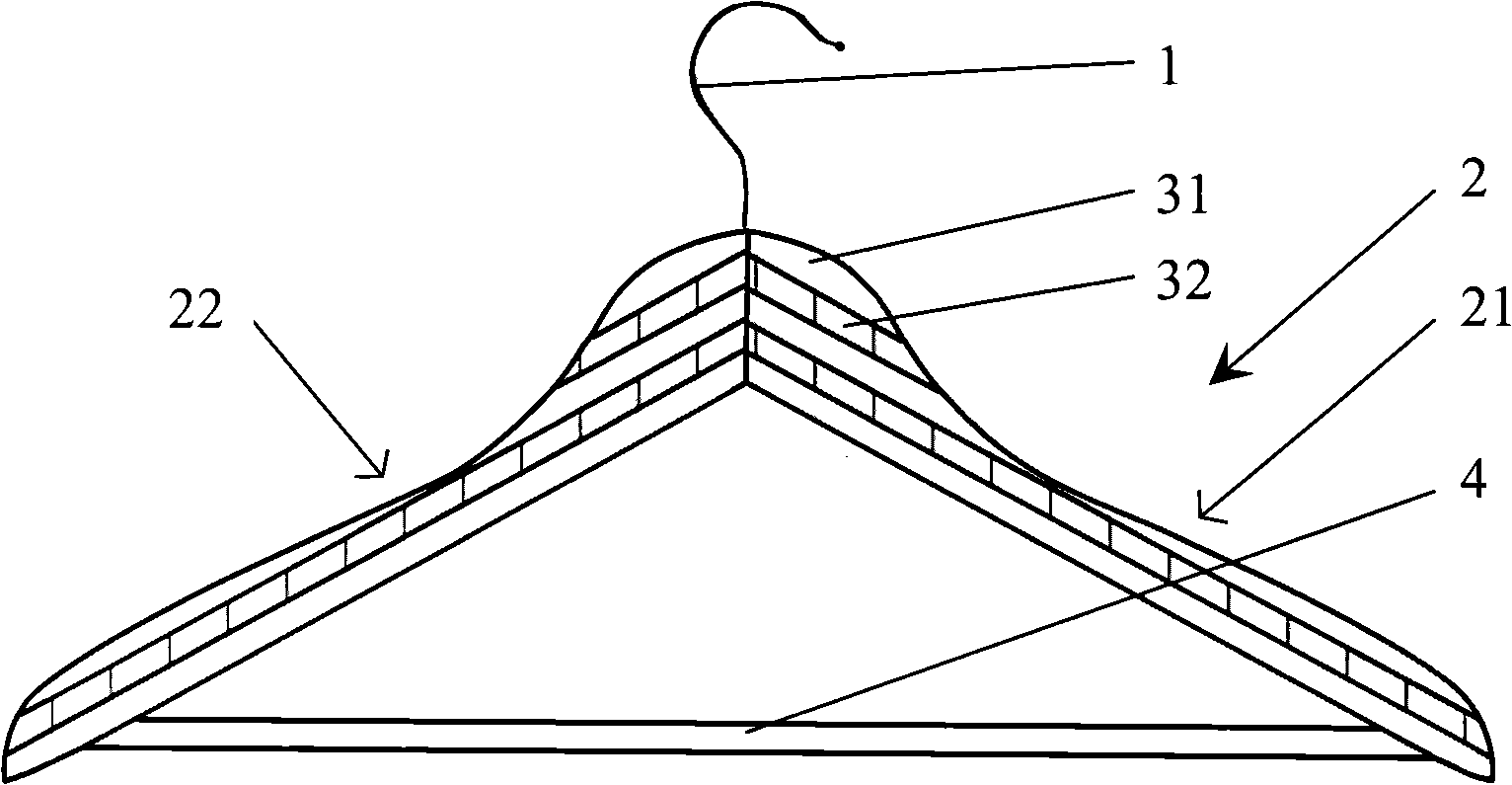

[0034] Such as figure 2 Shown is a schematic diagram of a preferred implementation of the second embodiment of the present invention. In this embodiment, the main body 2 is made of side-pressed panels of primary-colored bamboo pieces 31 and carbonized-colored bamboo pieces 32 .

[0035] The difference between this embodiment and the first embodiment is: after the original color bamboo blanks 31 have been treated with anti-corrosion and drying, a part of the original color bamboo chips 31 have been carbonized, and different temperatures, times, and pressures have been set in the carbonization furnace. Bamboo slices are carbonized in batches to obtain bamboo slices with different carbonized colors. The technical requirements for carbonization are: the temperature is between 120 degrees Celsius and 150 degrees Celsius, the boiler pressure is greater than 8 kg, and the processing time is 60-90 minutes. After the carbonization of the bamboo chips in the furnace is completed and co...

no. 3 example

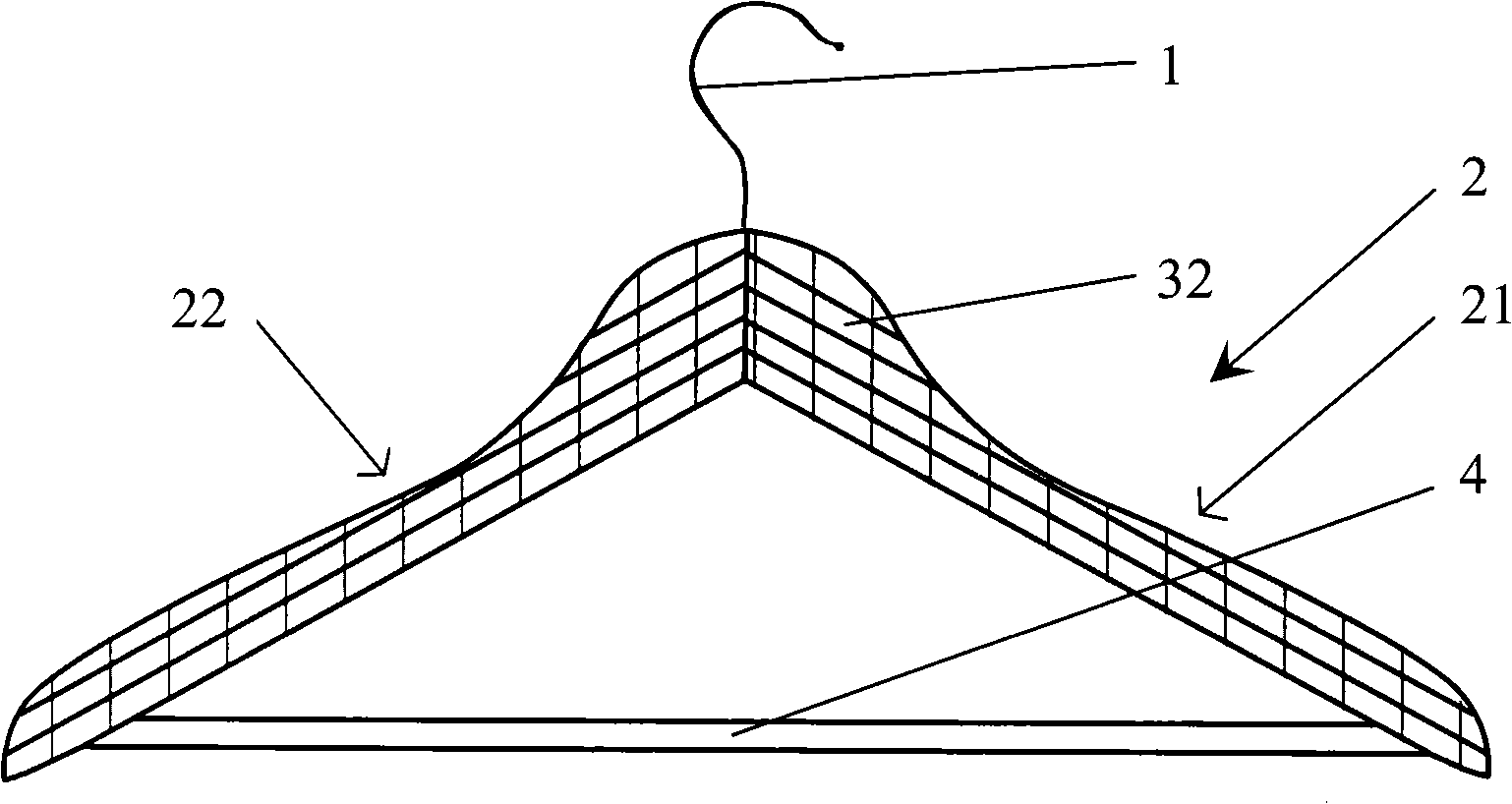

[0037] Such as figure 2 Shown is a schematic diagram of a preferred implementation of the third embodiment of the present invention. In this embodiment, the body 2 is made of side-pressed panels of primary-colored bamboo 31 and carbonized-colored bamboo 32 .

[0038] The difference between this embodiment and the second embodiment is: after the original color bamboo chips 31 are subjected to anti-corrosion and drying treatment, carbonization treatment is carried out, and different temperatures, times and pressures are set in the carbonization furnace to carbonize the bamboo chips in batches. In order to obtain bamboo chips with different carbonization colors, the technical requirements for carbonization treatment are as follows: the temperature is between 120 degrees Celsius and 150 degrees Celsius, the boiler pressure is greater than 8 kg, and the treatment time is 60-90 minutes. After the carbonization of the bamboo pieces in the furnace is completed and cooled, the bamboo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com