Physiotherapy electrode plate clamping self-pasting medicine carrying membrane and manufacture method thereof

A drug-loaded film and self-adhesive technology, which is applied in the direction of electrodes, electrotherapy, and pharmaceutical formulations, can solve the problems of reducing the adhesive performance of conductive adhesives, reducing application flexibility, and increasing production costs, so as to overcome the problem of high price, The effect of reducing competition transmission and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

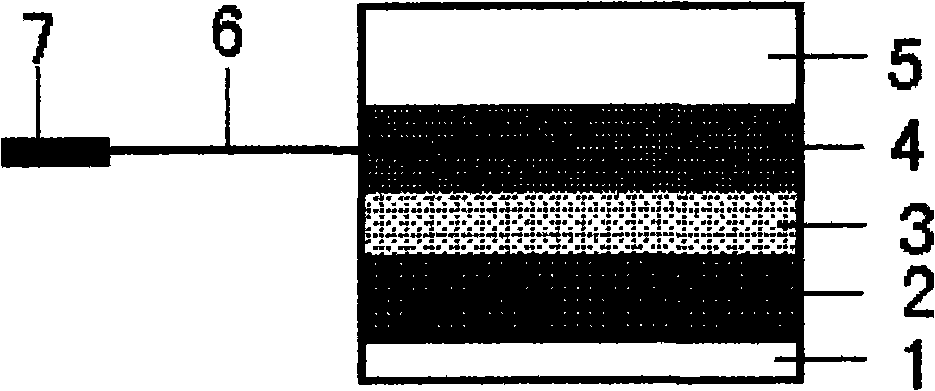

[0029] 1. Preparation of buffer layer gel material

[0030] 2 grams of chitosan with a molecular weight of 300,000 and 3 grams of polyvinyl alcohol 17-99 were dissolved in 100 mL of lactic acid solution with a mass concentration of 2% and 30 mL of distilled water, and then the two solutions were mixed until uniform. While stirring, 32 grams of mass concentration are 25% gelatin (molecular weight is 150,000) solution, 40mL pH6.5 acetate buffer solution, 50 grams of mass concentration are 30% maltooligosaccharide, 50 grams of mass concentration are 40% Sucrose oligosaccharides, 3 grams of glycerin, 0.1 grams of sodium benzoate and 10 grams of KCl solution with a mass concentration of 10% were added to the mixed solution, thoroughly mixed at 40-45° C. and then degassed.

[0031] 2. Preparation of drug release layer gel material

[0032] Dissolve 2 grams of carbomer 940 in 50 mL of distilled water, add 4 grams of triethanolamine under stirring to gel the carbomer solution, and mi...

Embodiment 2

[0036] The preparation process of the buffer layer gel material is the same as that of Example 1, except that the pH6.5 acetate buffer solution is changed to the pH7.2 phosphate buffer solution.

[0037] The preparation process of the drug release layer gel material is the same as that of Example 1.

[0038] The preparation process of the physiotherapy electrode sheet sandwiching the self-adhesive drug-loaded film is the same as that of Example 1. In the physiotherapy electrode sheet sandwiched with the self-adhesive drug-loaded film, the thickness of the buffer layer is 0.5 mm, and the thickness of the drug-releasing layer is 0.5 mm. 0.5mm.

Embodiment 3

[0040] The preparation process of the buffer layer gel material is the same as that of Example 1, except that the pH6.5 acetate buffer solution is changed to the pH7.6 phosphate buffer solution.

[0041] The preparation process of the drug release layer gel material is the same as that of Example 1.

[0042] The preparation process of the physiotherapy electrode sheet sandwiching the self-adhesive drug-loaded film is the same as that of Example 1. In the physiotherapy electrode sheet sandwiched with the self-adhesive drug-loaded film, the thickness of the buffer layer is 0.5 mm, and the thickness of the drug-releasing layer is 0.5 mm. 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com