Manufacturing method of low-consumption silver heterojunction solar cell

The technology of a solar cell and a manufacturing method, which is applied in the field of solar cells, can solve the problems of increasing the consumption of silver paste and increasing the production cost of heterojunction solar cells, and the high cost, so as to reduce the amount of silver paste used, reduce the cost of electrodes, and ensure the welding ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

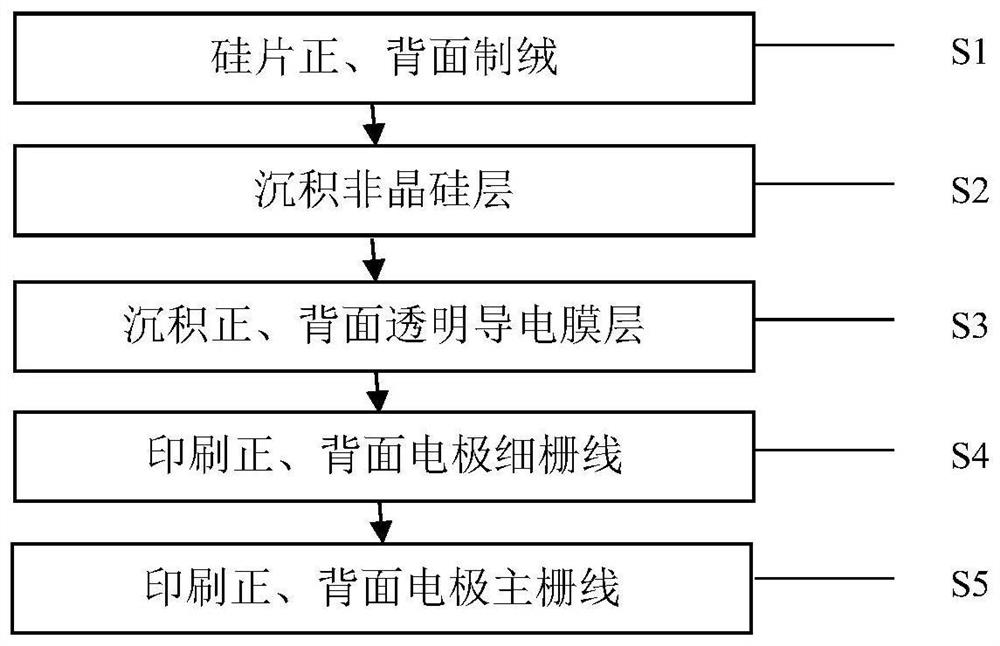

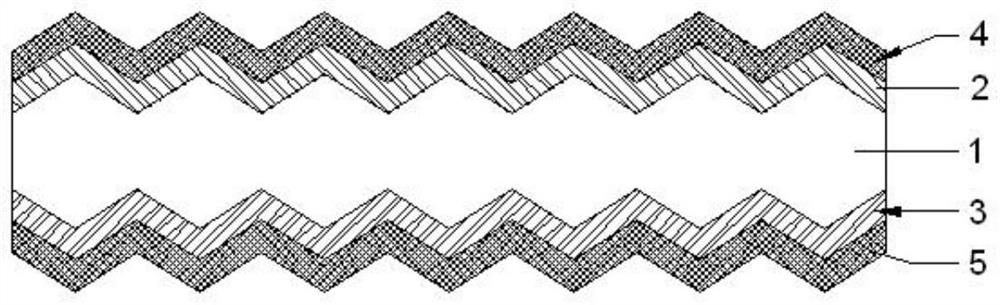

[0021] A method for manufacturing a low-consumption silver heterojunction solar cell, the steps of which are as follows:

[0022] A, preparing a heterojunction solar cell to be formed with a metal grid line;

[0023] B. Using silver paste with a silver content of 90%-97% to form the first silver paste electrode thin grid line and the second silver paste on the first main surface and the second main surface of the heterojunction solar cell obtained through step A Slurry electrode fine grid line;

[0024] C. Use silver-copper paste, nickel paste, copper paste or silver paste with a silver content of 30%-60% to form the second main surface and the second main surface of the heterojunction solar cell treated in step B respectively. A silver paste electrode main grid line and a second silver paste electrode main grid line.

[0025] The first silver paste electrode main grid lines and the first silver paste electrode thin grid lines are crossed horizontally and vertically, so that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com