Preparation for monodisperse, argentic sulfide and silver selenide nanocrystal

A silver nanocrystal, monodisperse technology, applied in the direction of alkali metal sulfide/polysulfide, copper sulfide, nanotechnology, etc., can solve the problems of poor product quality stability, high reaction toxicity, difficult mass production, etc., to achieve reaction toxicity Small size, short reaction time and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A method for preparing monodisperse silver nanocrystals, which specifically includes the following steps: putting 0.1 g to 1 g of silver nitrate into 10 ml of octadecylamine solvent, and reacting at a temperature of 160° C. to 300° C. for 1 to 10 minutes ; After the reaction precipitate is washed with ethanol, it is dried at a temperature of 40° C. to 80° C. to obtain monodisperse silver nanocrystals with a particle size of 6 to 12 nanometers.

[0016] The chemical equation of the above reaction is as follows:

[0017]

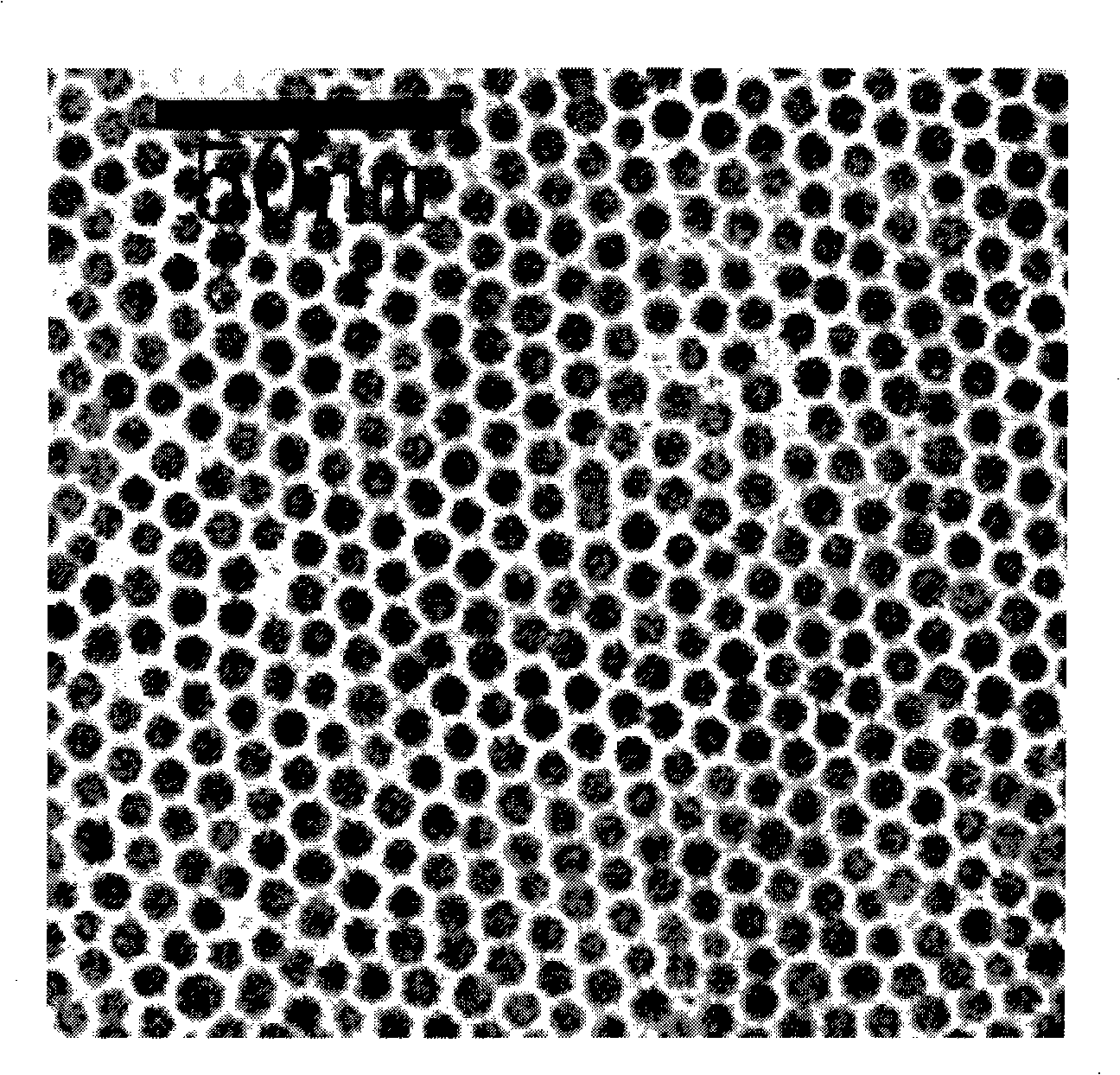

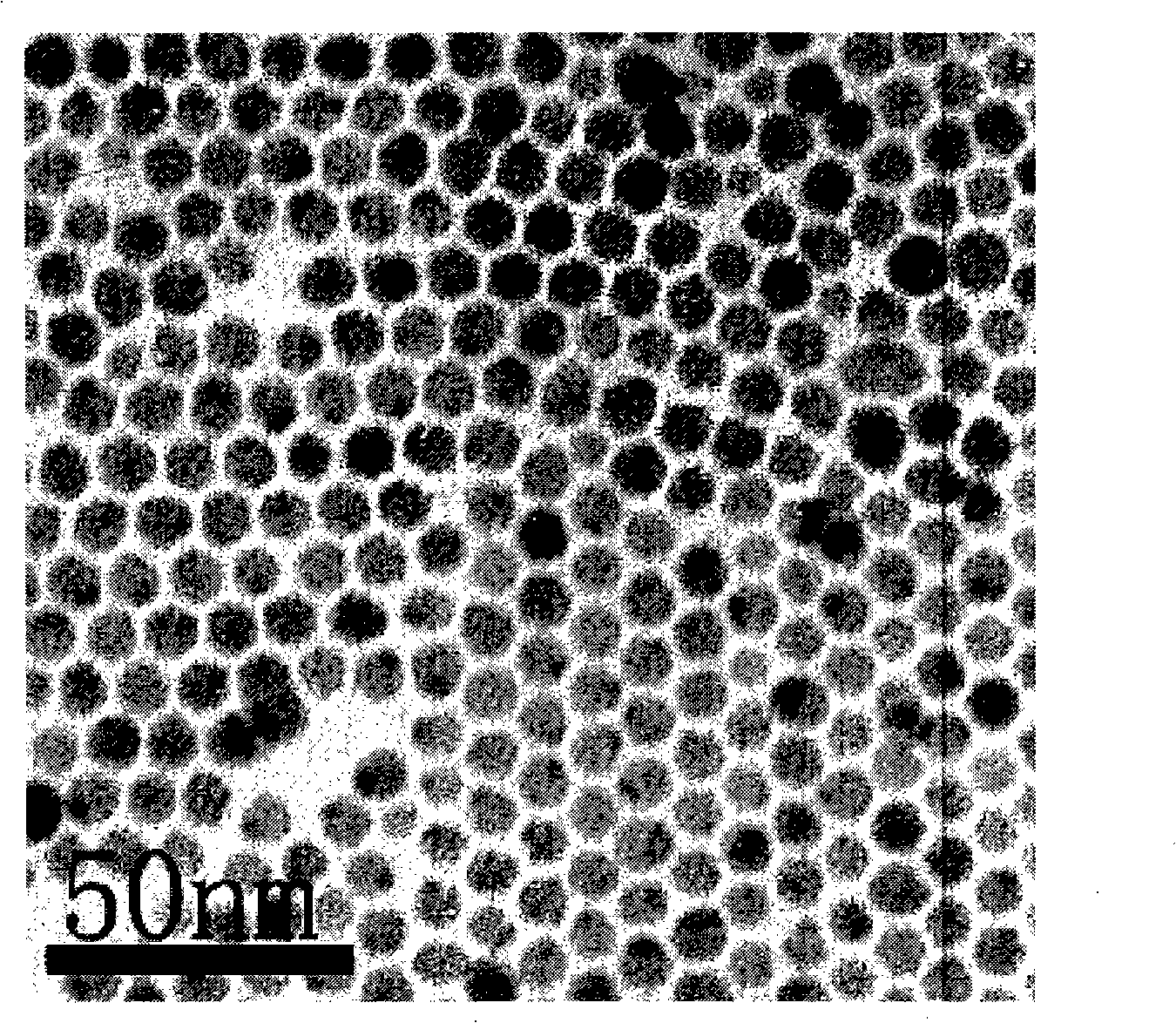

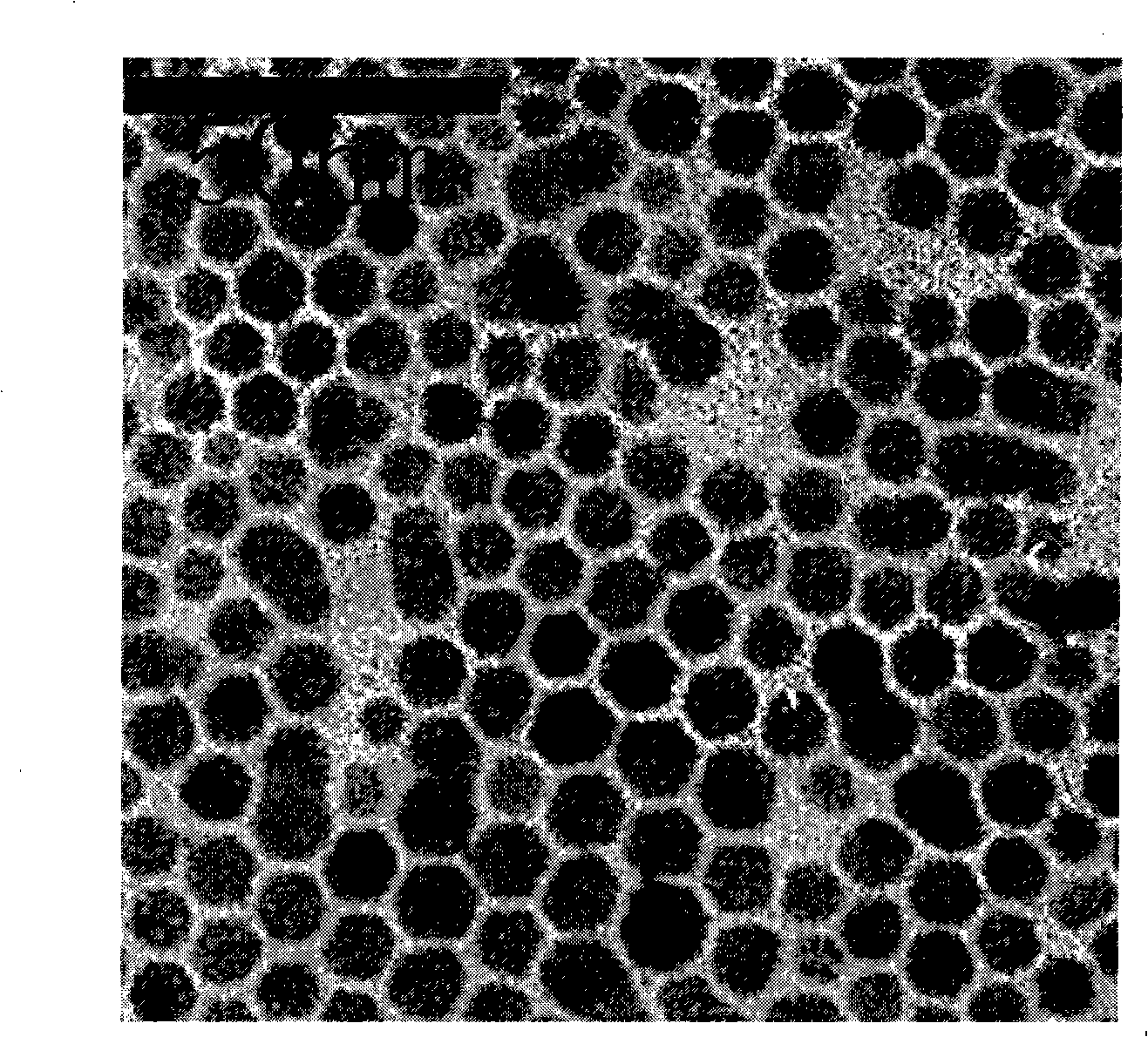

[0018] see figure 1 Transmission electron microscope (TEM) photographs of monodisperse silver nanocrystals prepared for the examples of the present invention.

[0019] A method for preparing monodisperse silver sulfide nanocrystals, comprising the following steps: putting 0.1 gram to 1 gram of silver nitrate into 10 milliliters of octadecylamine solvent, and reacting at a temperature of 160°C to 300°C for 1 to 10 minutes ; Put the sulfur powder int...

Embodiment 1

[0032] Take 10 milliliters (ml) of octadecylamine and heat it to 200°C, add 1 gram (g) of silver nitrate solid to it, keep it at 200°C for 10 minutes, wash the precipitate obtained by the reaction with ethanol, Dry at a temperature of 80° C. to obtain monodisperse silver nanocrystals with a particle size of 4.7 nm.

Embodiment 2

[0034] Take 10ml of octadecylamine and heat it to 200°C, add 0.85g of silver nitrate solid into it, keep it at 200°C for 10 minutes, and then add 0.08g of sulfur powder to react for 10 minutes. The precipitate obtained from the reaction is washed with ethanol and dried at a temperature of 40° C. to 80° C. to obtain monodisperse silver sulfide nanocrystals with a particle size of 7.3 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com