Fluid-filled type vibration damping device and method of manufacturing the same

一种减振装置、流体填充的技术,应用在减振器、动力装置、喷气推进装置等方向,能够解决分开、肉眼检查评价预处理质量、粘合缺陷等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

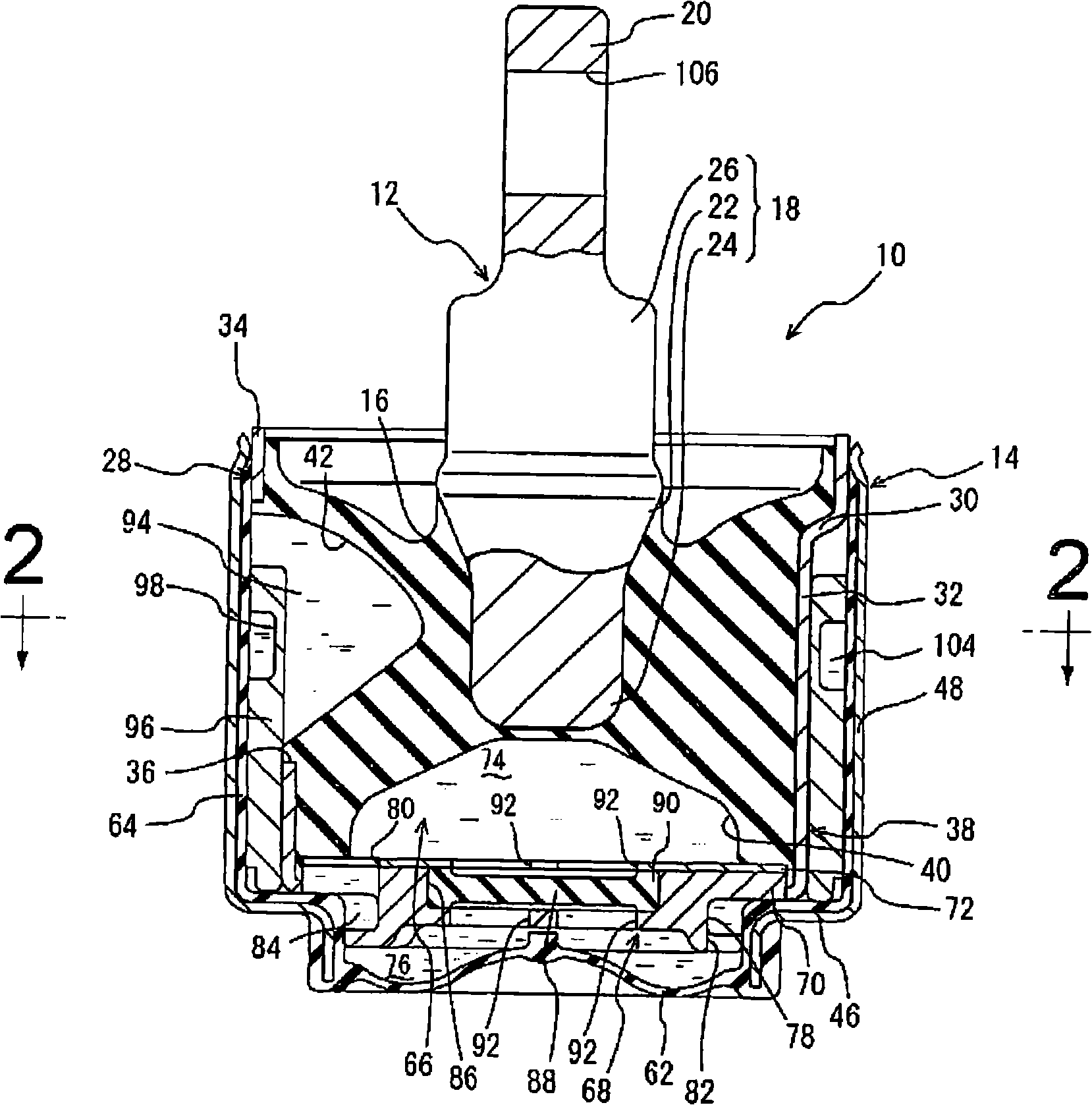

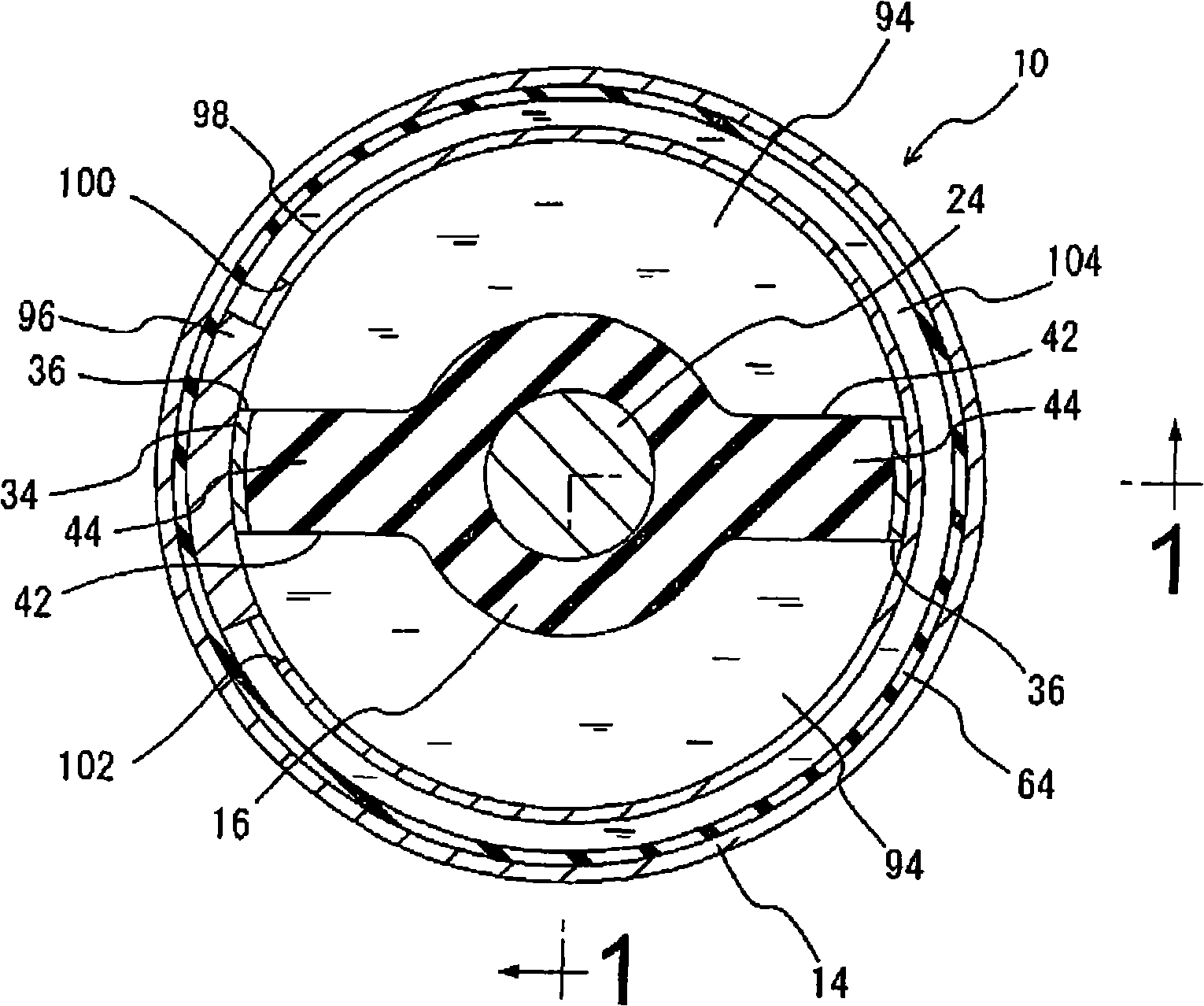

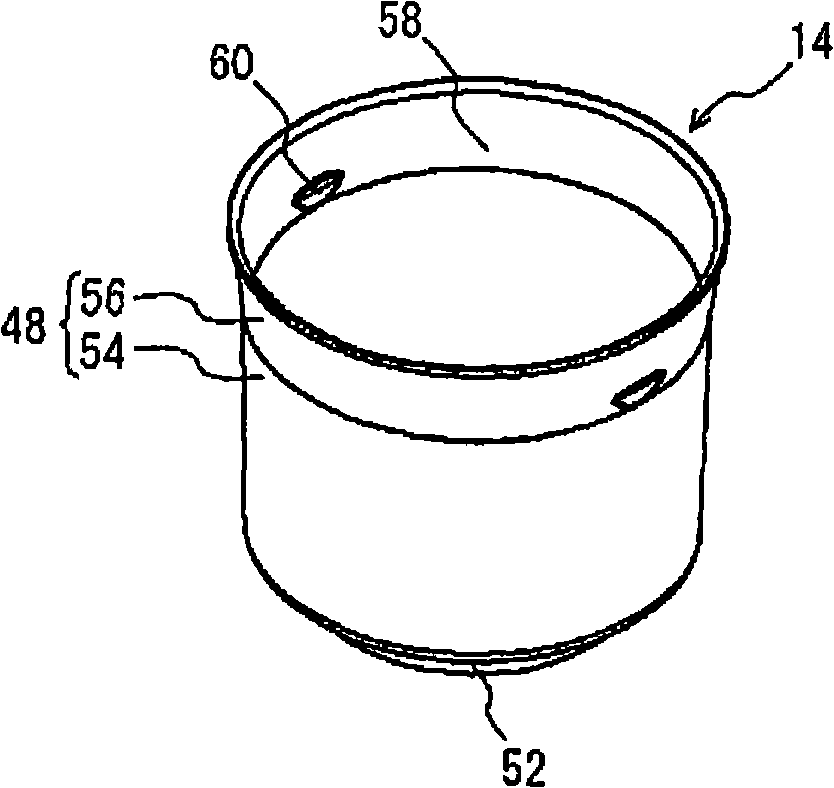

[0045] figure 1 and figure 2 A vehicle engine mount 10 is shown as a fluid-filled vibration damping device according to an embodiment of the present invention. This engine mount 10 has a structure in which a metal inner shaft member 12 serving as an inner mounting member and a metal outer cylindrical member 14 serving as an outer cylindrical mounting member are positioned to be spaced apart from each other, and the inner shaft member 12 and the outer cylinder The shape members 14 are connected by a main rubber elastic body 16 . The inner shaft member 12 is mounted to the power plant of the vehicle, while the outer cylindrical member 14 is mounted to the vehicle body to provide vibration-damping support of the power plant on the vehicle body. exist figure 1 The engine mount 10 of the present embodiment is installed in an orientation in which the vertical direction is substantially aligned with the vertical direction. Here, the vertical direction in principle means figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com