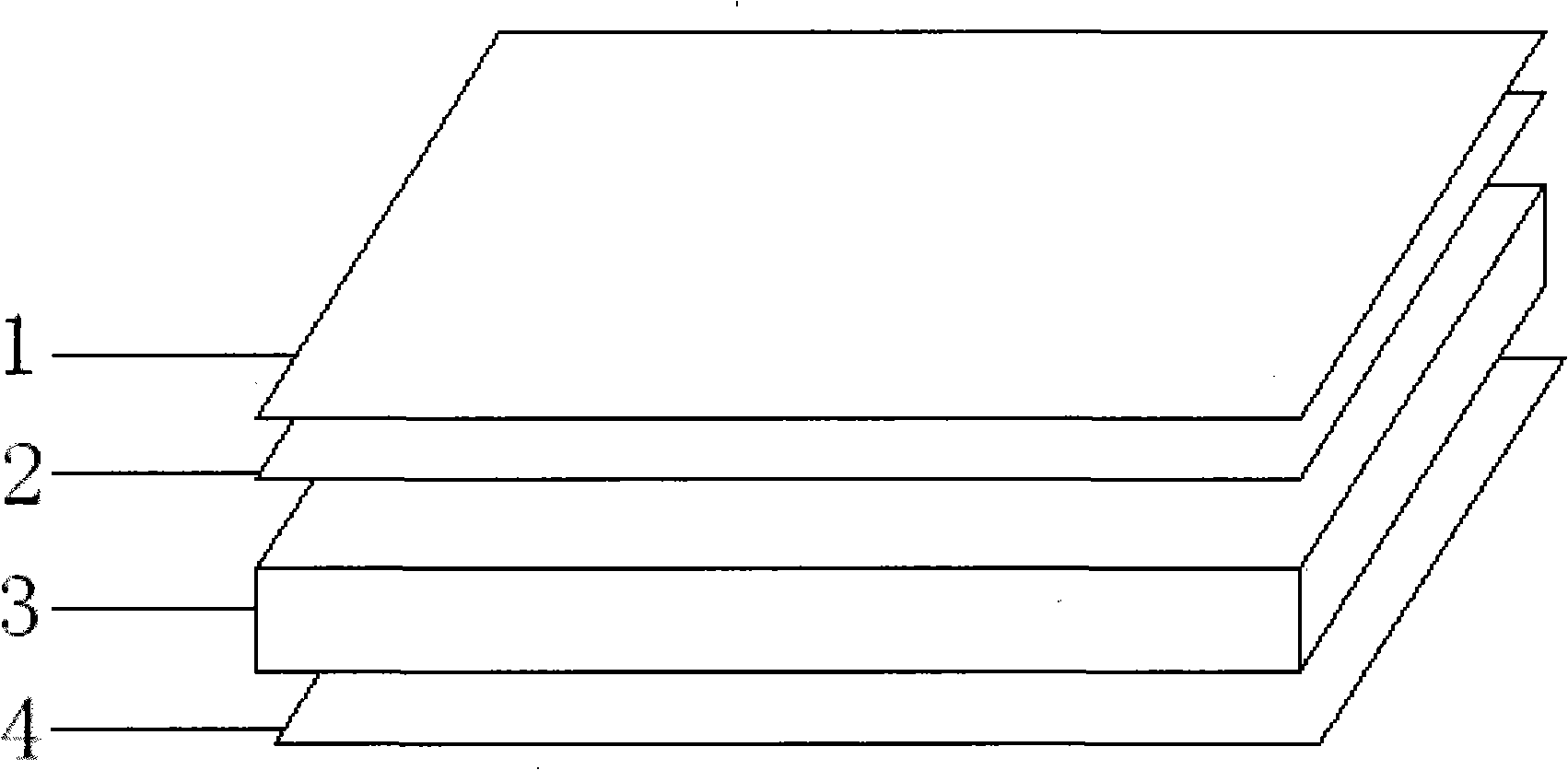

Steel face type phenolic aldehyde heat preserving composite board and manufacturing method and application thereof

A technology of phenolic heat preservation and manufacturing method, which is applied in the directions of heat preservation, pipeline protection, and pipeline protection by heat insulation, etc., can solve the problems of easy bumping, easy to be damaged, insufficient strength, etc. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The prefabricated 0.1mm thick galvanized steel sheet with the adhesion-promoting layer is entered into an oven at 80° C. for preheating. Toughening agent: curing agent = 100: 1: 8: 5: 10) is poured on it (to ensure that the thickness of the foam is 20mm), and enters the composite insulation board continuous production line together with the aluminum foil as the other surface layer for foaming and curing. Finally, according to the specifications, it is cut into a certain length of composite board and trimmed and packaged. This product is used as an air duct plate for the air supply duct of the central air conditioner in a large building.

[0032] The surfactant is silicone oil, the foaming agent is 141b, the toughening agent is polyethylene glycol, and the curing agent is 10% sulfuric acid.

Embodiment 2

[0034] The prefabricated 0.5mm thick tinplate plate with the tackifying layer is entered into an oven at 80°C for preheating, and after preheating, the proportioned mixture (expandable phenolic resin: surfactant: foaming agent: Toughening agent: curing agent = 100: 2: 1: 8: 4) is poured on it (to ensure that the thickness of the foam is 20mm), and enters the composite insulation board continuous production line together with the aluminum plate as the other surface layer for foaming and curing. Finally, according to the specifications, it is cut into a certain length of composite board and trimmed and packaged. This product is used as an air duct plate for the air supply duct of the central air conditioner in a large building.

[0035]The surfactant is an EL emulsifier, the foaming agent is a hydrocarbon foaming agent, the toughening agent is polyethylene glycol, and the curing agent is 10% p-toluenesulfonic acid.

Embodiment 3

[0037] Put the prefabricated 0.15mm thick color steel plate with an adhesion-promoting layer into an oven at 80°C for preheating. Toughening agent: curing agent = 100: 3: 6: 7: 12) is poured on it (to ensure that the thickness of the foam is 20mm), and enters the composite insulation board continuous production line together with the aluminum foil paper as the other surface layer for foaming and curing. Finally, according to the specifications, it is cut into a certain length of composite board and trimmed and packaged. This product is used as an air duct plate for the air supply duct of the central air conditioner in a large building.

[0038] The surfactant is silicone oil, the foaming agent is 141b, and the toughening agent is polyvinyl alcohol. The curing agent is 13% phosphoric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com