Nitrogen gas conveying device

A nitrogen delivery and liquid nitrogen storage tank technology, applied in boiling devices, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the problem of large loss of liquid nitrogen, damage to pipelines, and increase the extra work of workers load and other problems, to achieve the effect of improving the evaporation effect and the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

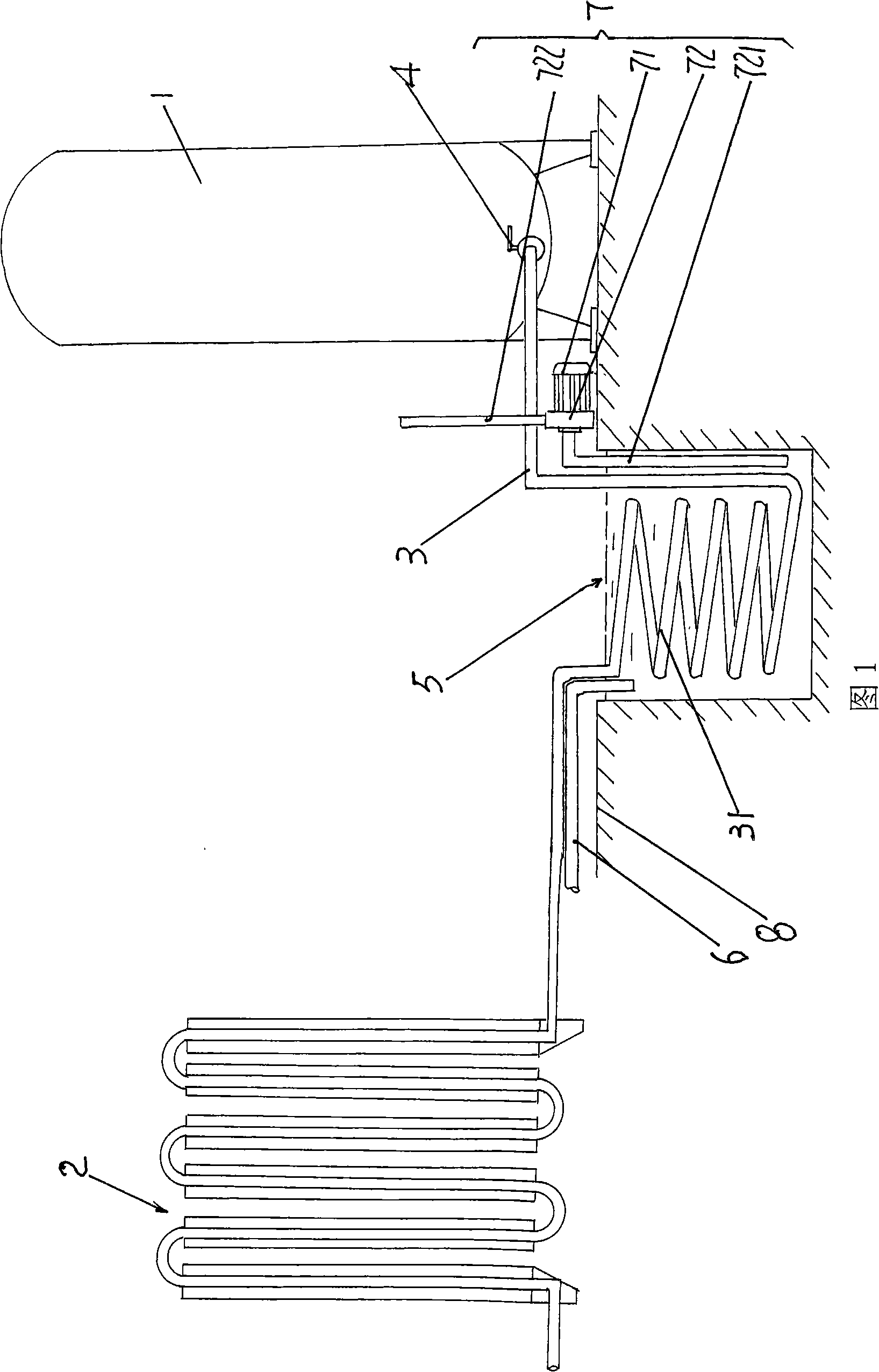

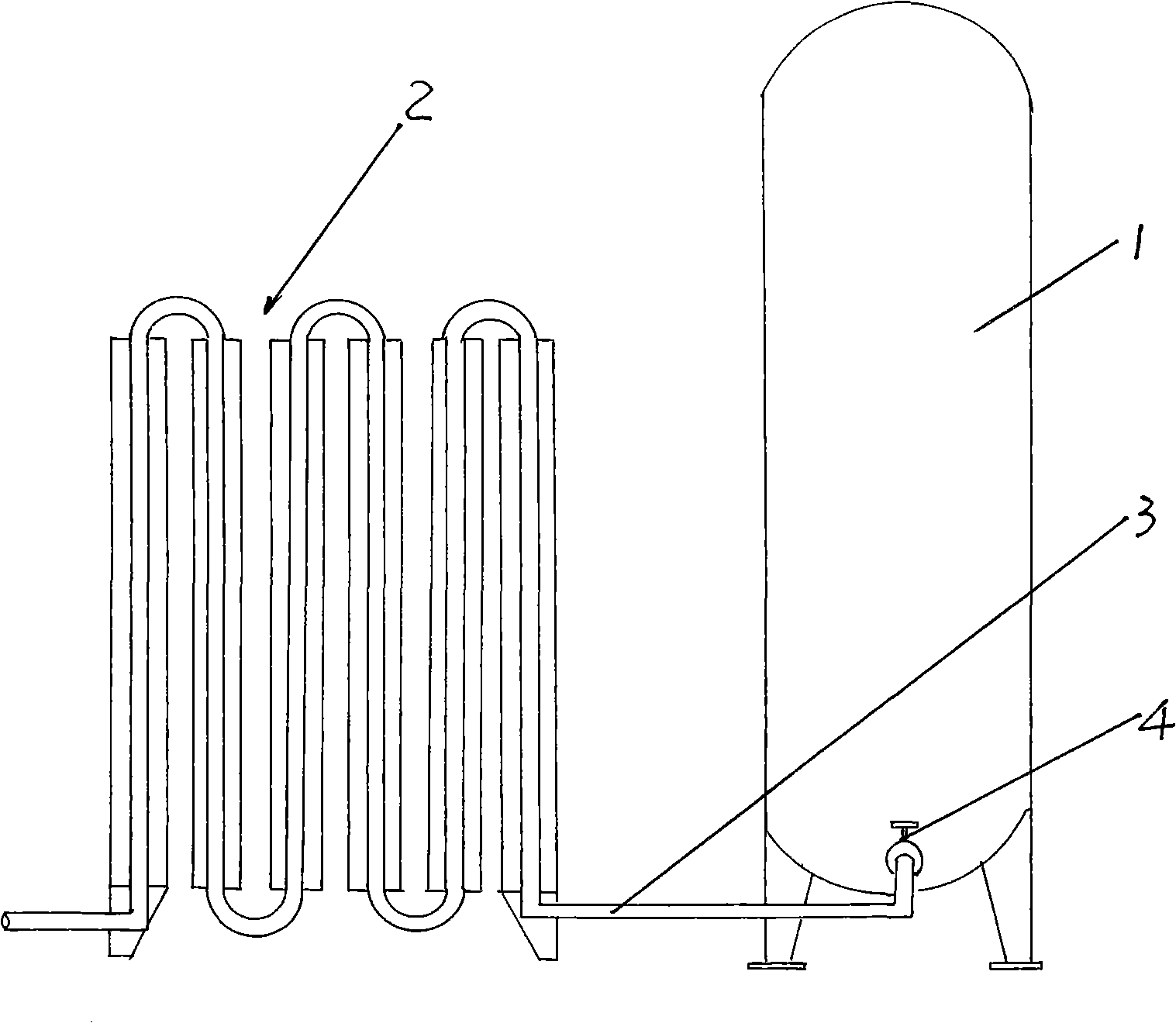

[0017] Please see Figure 1. Under normal circumstances, the liquid nitrogen storage tank 1 and the evaporator 2 are installed and fixed on the outdoor floor 8. One end of the pipeline 3 is connected to the liquid nitrogen storage tank 1, and the other end is connected to the evaporator 2. , open the valve 4, the liquid nitrogen in the liquid nitrogen storage tank 1 can be introduced into the evaporator 2 for evaporation through the pipeline 3, and the evaporation of the evaporator 2 makes the liquid nitrogen into gaseous nitrogen, that is, nitrogen, and introduces it into the furnace of the sintering kiln middle.

[0018] In the technical solution recommended by the present invention, the middle part of the pipeline 3 for transporting liquid nitrogen is processed into a curved pipe section 31 , and the curved pipe section 31 is placed into the equipped heat exchange tank 5 . In this embodiment, the selected heat exchange tank 5 is directly processed on the floor 8, that is, a ...

Embodiment 2

[0020] The figure is omitted, only the curved pipe section 31 is processed into a U shape, wherein the total length of the curved pipe section 31 is the same as that of Embodiment 1, and the rest are the same as the description of Embodiment 1.

Embodiment 3

[0022] The figure is omitted, and the curved shape of the curved pipe section 31 with the same total length as that of Embodiment 1 is formed into an S shape, and the rest are the same as the description of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com