Method for preparing thin-film transistor array substrate and liquid crystal display panel

A technology of thin film transistors and array substrates, which is applied in the field of manufacturing thin film transistor array substrates, can solve problems such as reduction, insufficient polysilicon film thickness, and distortion of measurement results, so as to increase the photosensitive area, improve light sensing performance, and avoid noise influence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

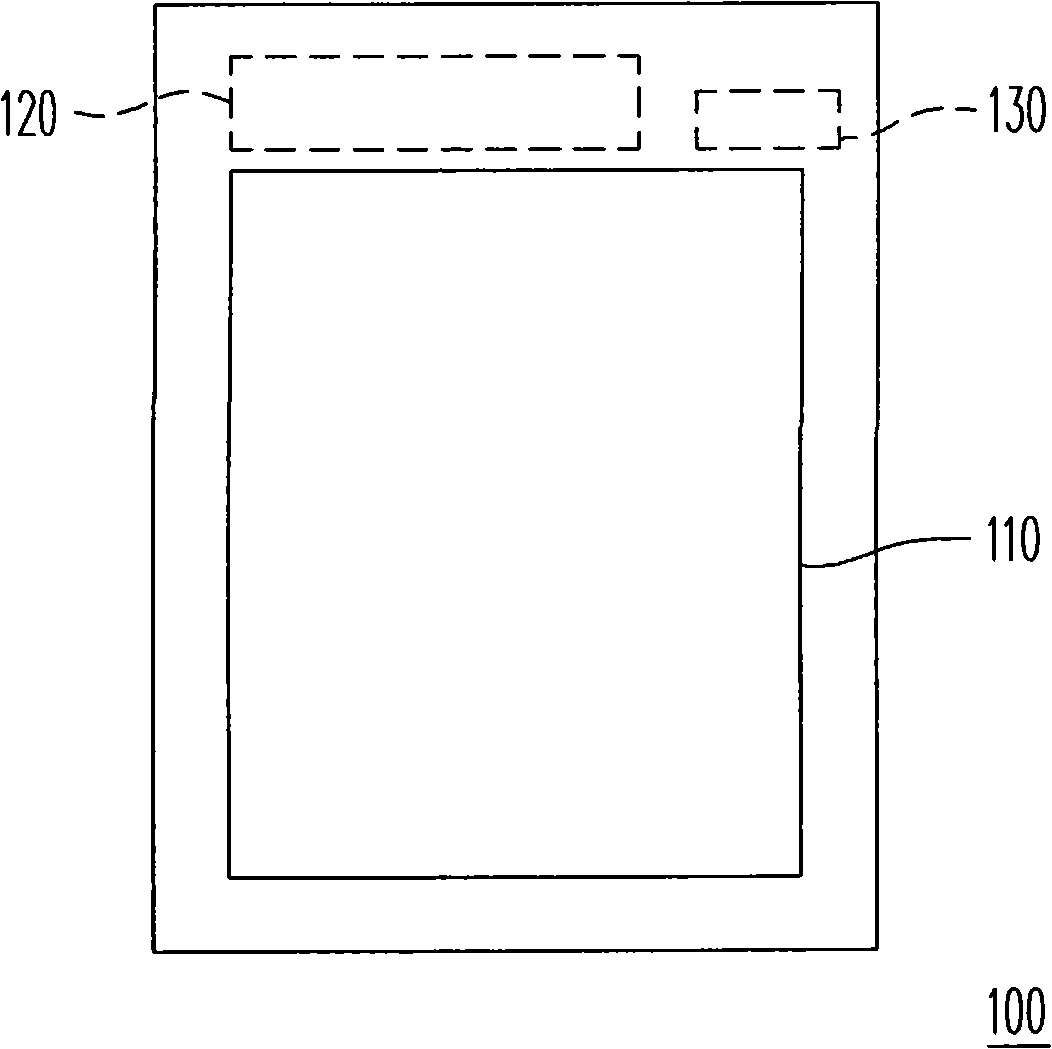

[0110] Please refer to figure 1 , which shows a layout of a liquid crystal display panel integrated with light sensors according to an embodiment of the present invention. like figure 1 As shown, the liquid crystal display panel 100 has at least a display area 110 and a peripheral circuit area 120 and a sensing area 130 located on the periphery of the display area 110 . There are a plurality of pixel units in the display area 110 to display a picture frame. Possible driving components, such as a scan driver or a data driver, are arranged in the peripheral circuit area 120 . The sensing area 130 is used to configure a light sensor to detect the intensity of ambient light, and accordingly adjust the brightness of the back-light of the display to achieve the effect of power saving. At the same time, by detecting the intensity of ambient light, the brightness and contrast of the liquid crystal display panel can also be automatically adjusted, which can not only alleviate eye fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com