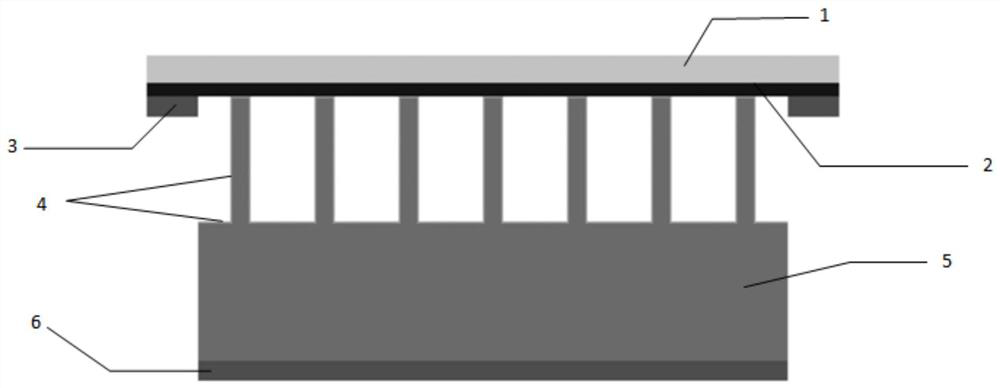

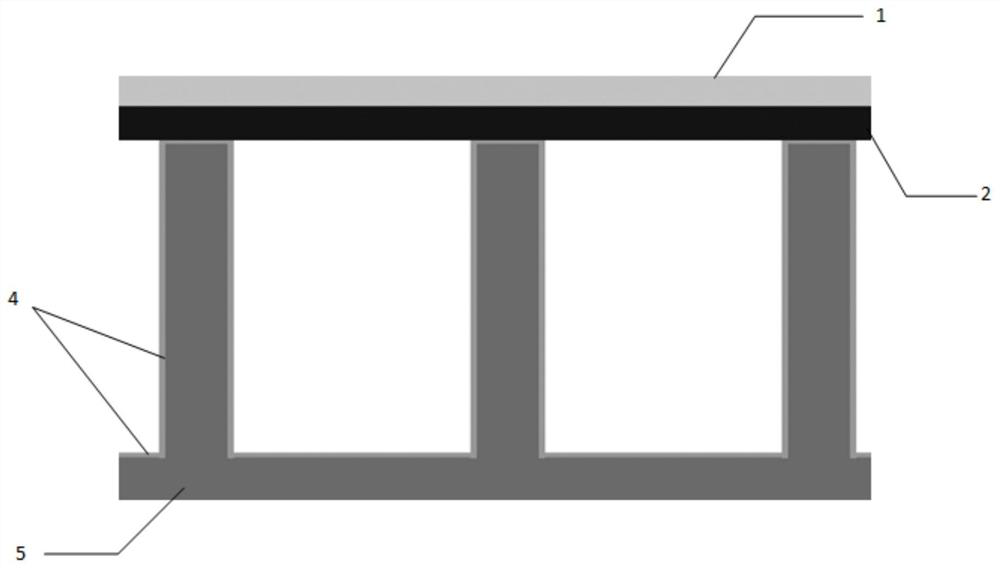

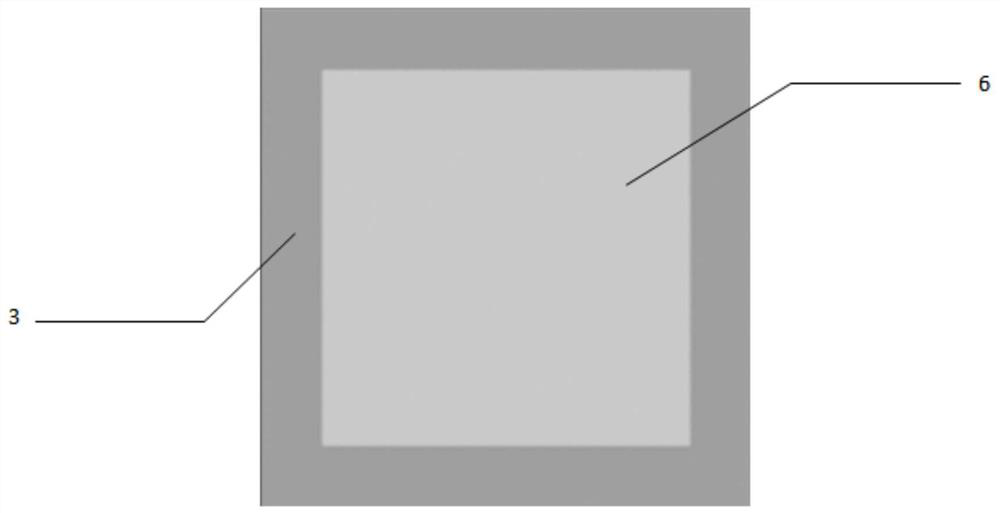

Photoelectric detector based on PtSe2 and silicon nanorod array and preparation method of photoelectric detector

A photodetector, silicon nanopillar technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for sensing, can solve the problem of low photoresponsivity of photodetector, small effective area of heterojunction, and degradation of device performance and other problems, to achieve the effect of improving the photoelectric conversion efficiency, increasing the effective contact area, and improving the integral sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Soak the cut copper foil (thickness 25 μm, purity 99.99%) in acetone for 5 minutes, then put it in an ultrasonic machine for 10 seconds, pour off the acetone and use ethanol to ultrasonically clean it for 5 minutes, and finally rinse it several times with deionized water. And blow off the surface moisture with a nitrogen gun. The treated copper foil is placed on the quartz slide and pushed to the position near the thermocouple in the heating zone in the middle of the outer end of the quartz tube. After evacuating to about 4Pa, argon is introduced to normal pressure, and the above process is repeated to reduce the oxygen content and prevent the copper foil from being oxidized under high temperature conditions. Keep the first path of Ar gas (Ar1, 500mL / min), H 2 (30mL / min) The flow rate remains unchanged, the program control is started for 90min, and the temperature is raised to 1000°C at a constant speed. Subsequent heat preservation and preheating treatment for 2 h...

Embodiment 2

[0065] 1. Cut the copper foil (thickness 25μm, purity 99.99%) into the required size, then ultrasonically clean it with acetone and alcohol for 15 minutes, then treat it with 20% dilute hydrochloric acid for 20 minutes, and finally add acetone, alcohol and Ultrasonic cleaning in deionized water for 10 min and blowing off the surface moisture with a nitrogen gun. The cleaned and dried copper foil is placed in the constant temperature zone of the tube furnace, and the sealed quartz tube is fed with Ar gas with a flow rate of 1100 sccm and hydrogen gas with a flow rate of 20 sccm, and the tube furnace is heated to 1000 °C at a heating rate of 10 °C / min. Subsequently, the hydrogen flow rate was adjusted to 100 sccm for heat preservation and preheating treatment for 60 minutes, so that the arrangement of copper atoms tended to be consistent, and at the same time, the surface activity of copper foil was improved, thereby promoting the deposition of carbon atoms. After the heat prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com