Preparation method of hydrogenation catalyst

A hydrotreating and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. Action, performance improvement, and aggregation-suppressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] In the preparation process of the catalyst of the present invention, the organic compound additive is loaded on the catalyst carrier first, so that the organic compound and the carrier form a certain combination, and then during and / or after the carrier loaded with the organic compound additive is combined with the active metal, The organic compound additive is added again to improve the dispersibility of the active metal component and further improve the performance of the catalyst.

[0015] A kind of concrete preparation process of catalyst of the present invention comprises the following steps:

[0016] 1. Preparation of porous carrier;

[0017] 2. impregnating the carrier described in step 1 with the organic compound additive solution;

[0018] 3. Drying the carrier carrying the organic additive described in step 2 at a condition lower than the calcination temperature;

[0019] 4. During and / or after combining the dried organic matter-loaded carrier described in s...

Embodiment 1

[0039] The catalyst is prepared using ethylene glycol.

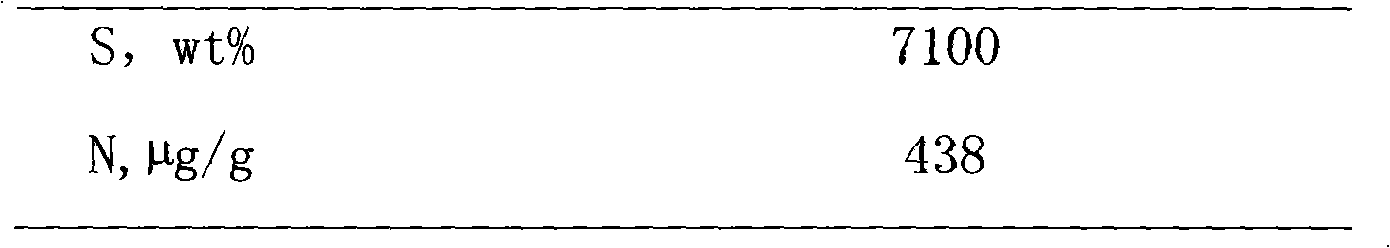

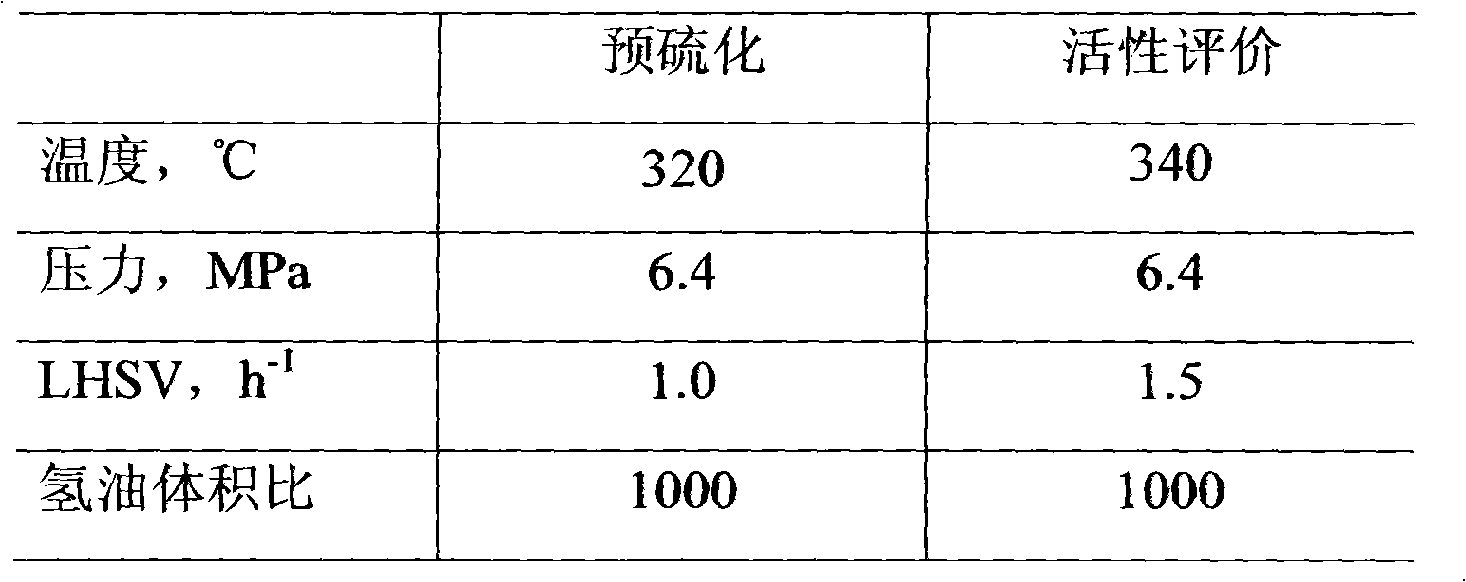

[0040] Reference catalyst CA was prepared as follows. Catalysts were prepared using gamma-alumina carrier ZT (1.2mm, clover) with the following properties:

[0041] Pore volume: 0.75mL / g

[0042] Specific surface area: 320m 2 / g

[0043] Bulk density: 0.55g / mL

[0044] The gamma-alumina carrier was impregnated with an equal volume of aqueous impregnating solution containing an appropriate amount of molybdenum trioxide, nickel carbonate and phosphoric acid, and the impregnated carrier was dried at 100°C for 16 hours, and then the dried strip was calcined at 470°C for 3 hours in an air atmosphere. The prepared catalyst contains 12(w)% molybdenum (calculated as oxide), 3.2(w)% nickel (calculated as oxide) and 2(w)% phosphorus (calculated as P 2 o 5 count).

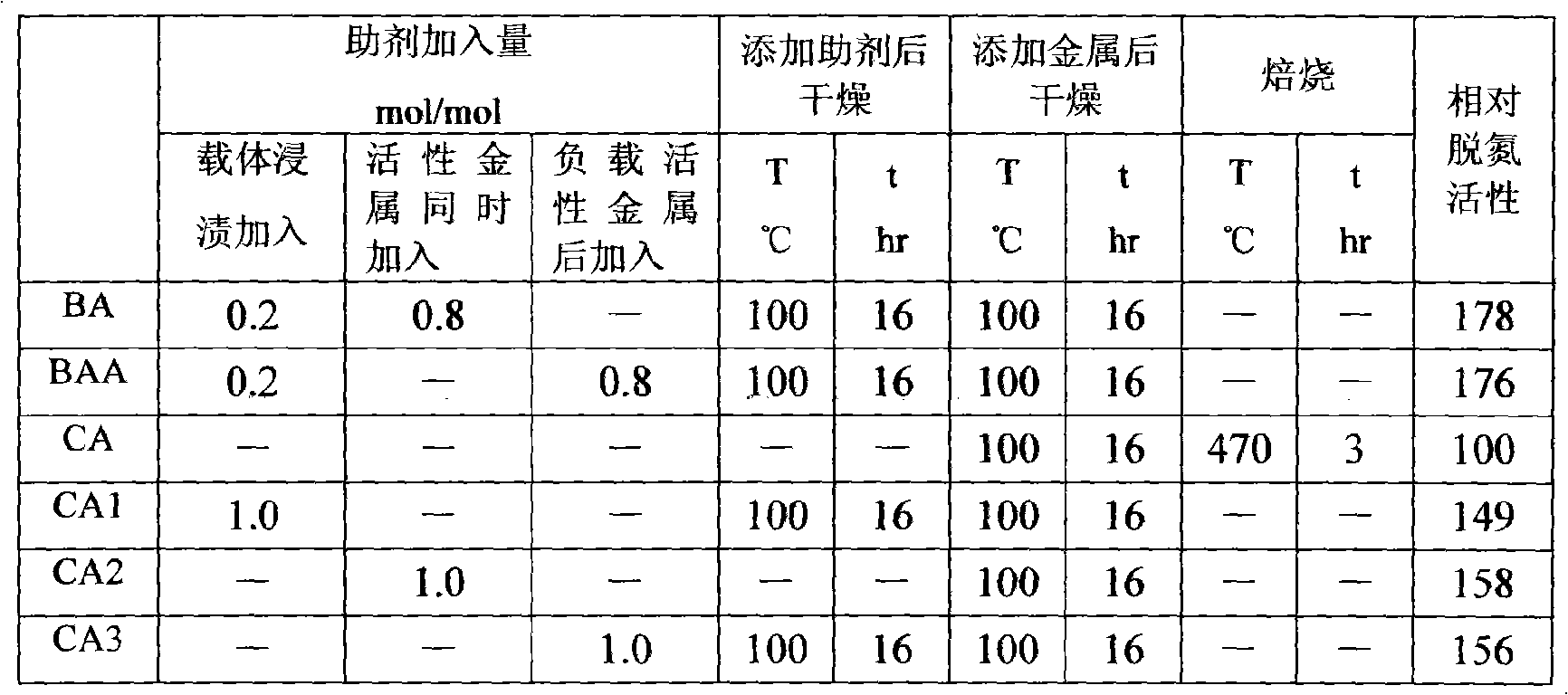

[0045] Catalyst BA of the present invention is to impregnate carrier ZT with equal volume of aqueous solution containing appropriate amount of ethylene glycol,...

Embodiment 2

[0060] Diethylene glycol was used to prepare the catalyst.

[0061] Diethylene glycol was used as an organic compound additive. The preparation method was repeated in Example 1.

[0062] According to the method described in Example 1, the catalyst was presulfided and evaluated for activity. The results are listed in Table 4.

[0063] Table 4 Catalyst Preparation Conditions and Activity Evaluation Results of Example 2

[0064]

[0065] Seen from Table 4, also, the present invention is obviously higher than the reference catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com