Exhaust gas purifier for diesel engine

An exhaust purification device, diesel engine technology, applied in exhaust devices, exhaust treatment, mufflers and other directions, can solve problems such as DPF blockage and burning, and achieve the effect of rapid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

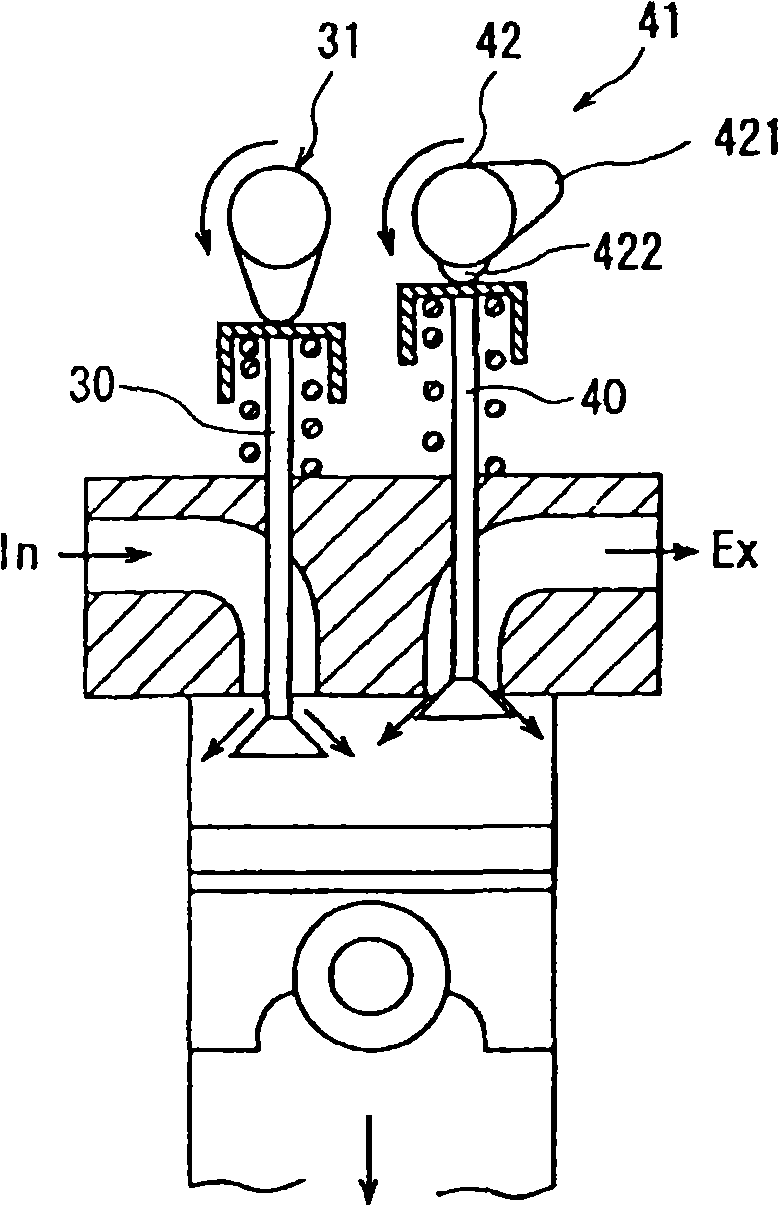

[0029] Next, an exhaust purification device for a diesel engine embodying the present invention will be described with reference to the drawings.

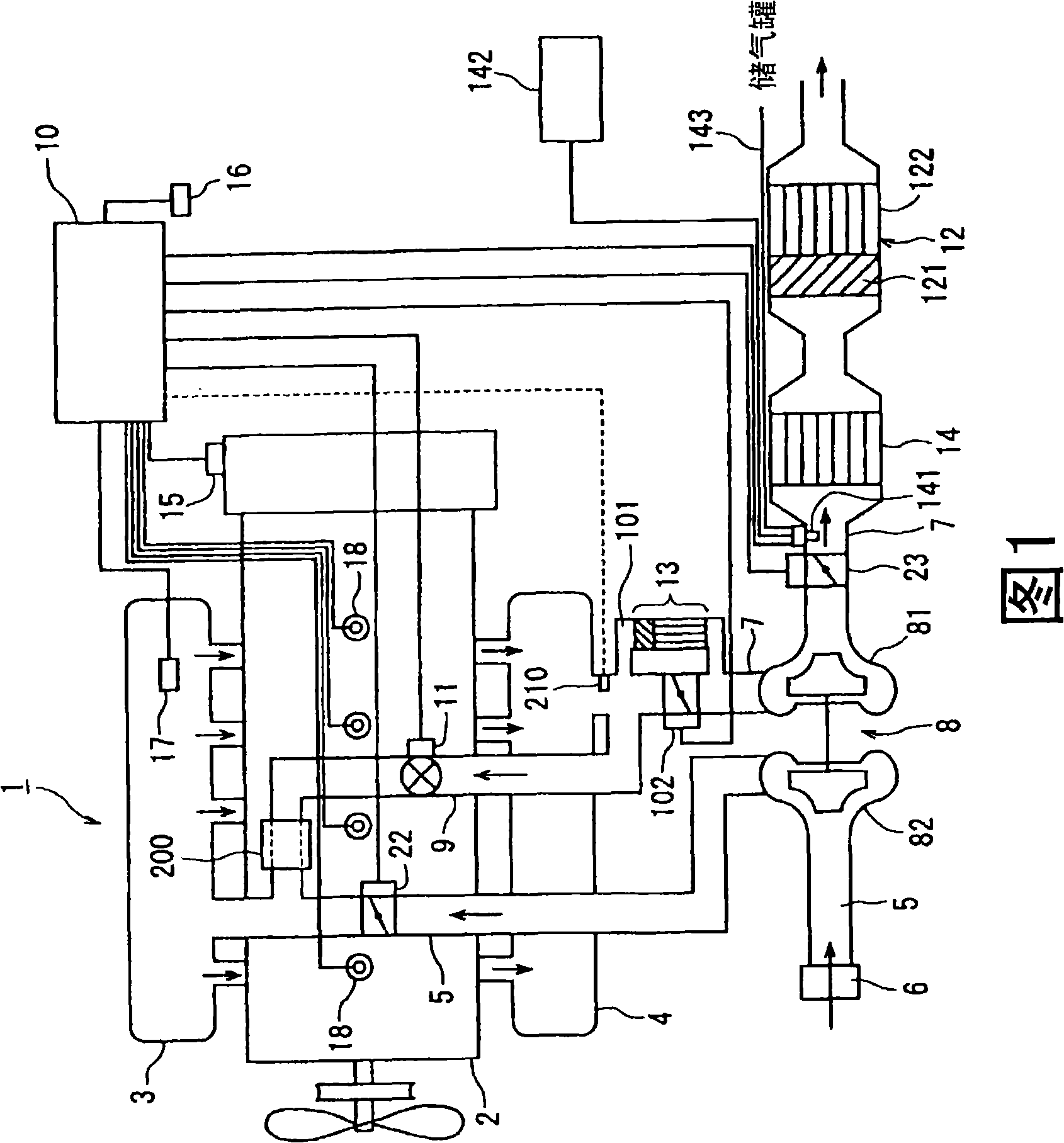

[0030] First, in FIG. 1 showing an overall schematic view of a diesel engine 1 according to the present invention, an intake manifold 3 constituting a part of an intake passage 5 and components are arranged in an engine main body 2 composed of a cylinder block and a cylinder head. Exhaust passage 7 is part of the exhaust manifold 4 . An air filter 6 for purifying intake air is provided at the most upstream portion of the intake passage 5 , and the intake air purified by the air filter 6 is supplied to the cylinder through the intake manifold 3 via the intake passage 5 . An exhaust passage 7 is connected to the exhaust manifold 4 , and the exhaust gas generated in the cylinder is discharged through the exhaust manifold 4 and the exhaust passage 7 .

[0031] The illustrated diesel engine includes a turbocharger 8 that supercharges i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com