Water processing reactor integrating photocatalysis and biological degradation and method thereof

A technology of biodegradation and photocatalysis, which is applied in the field of water treatment reactor and its treatment integrating photocatalysis and biodegradation, can solve the problems of reduced efficiency, increased treatment cost, and complicated treatment process, so as to change the structure, The effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The treatment of embodiment one refractory organic waste water

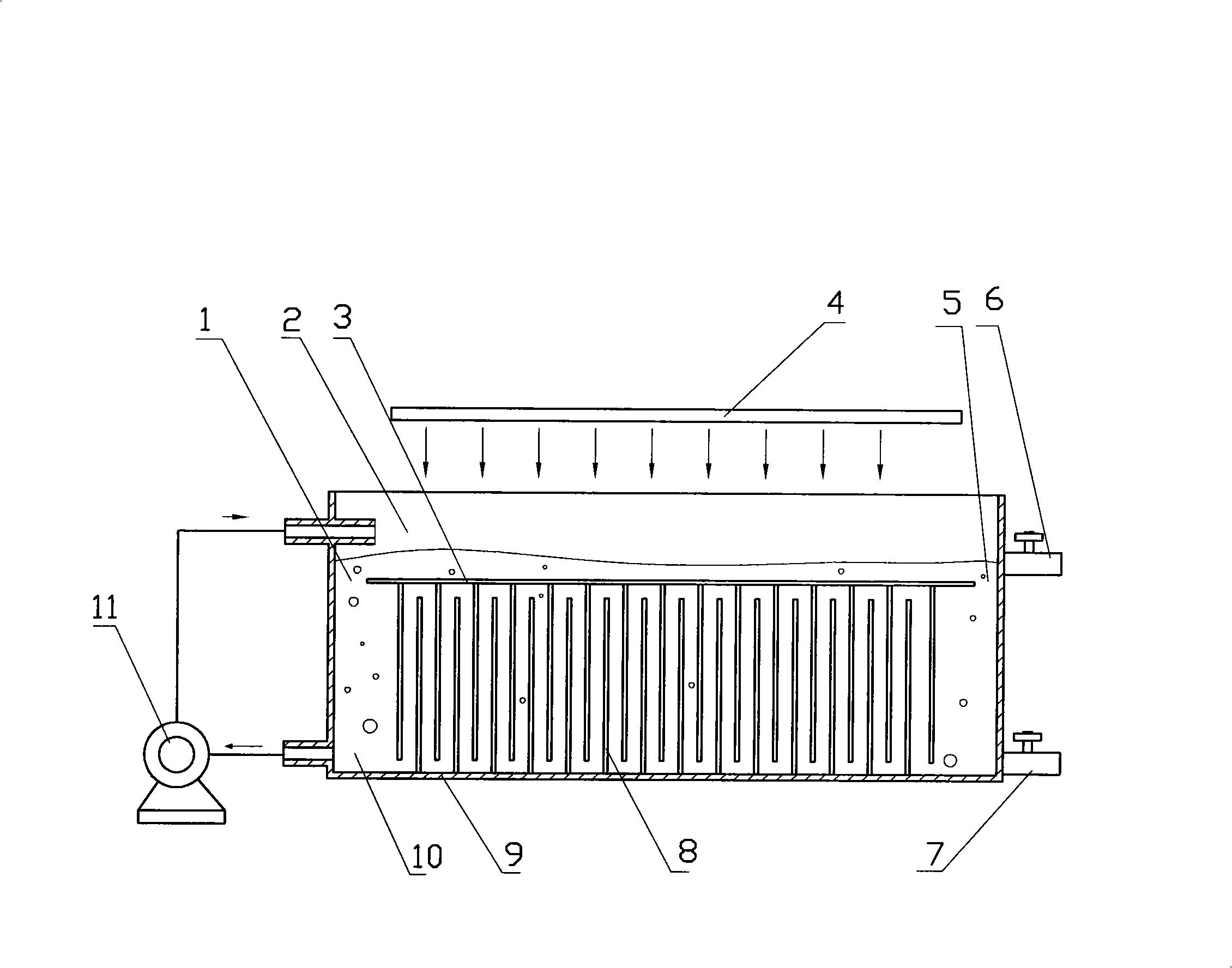

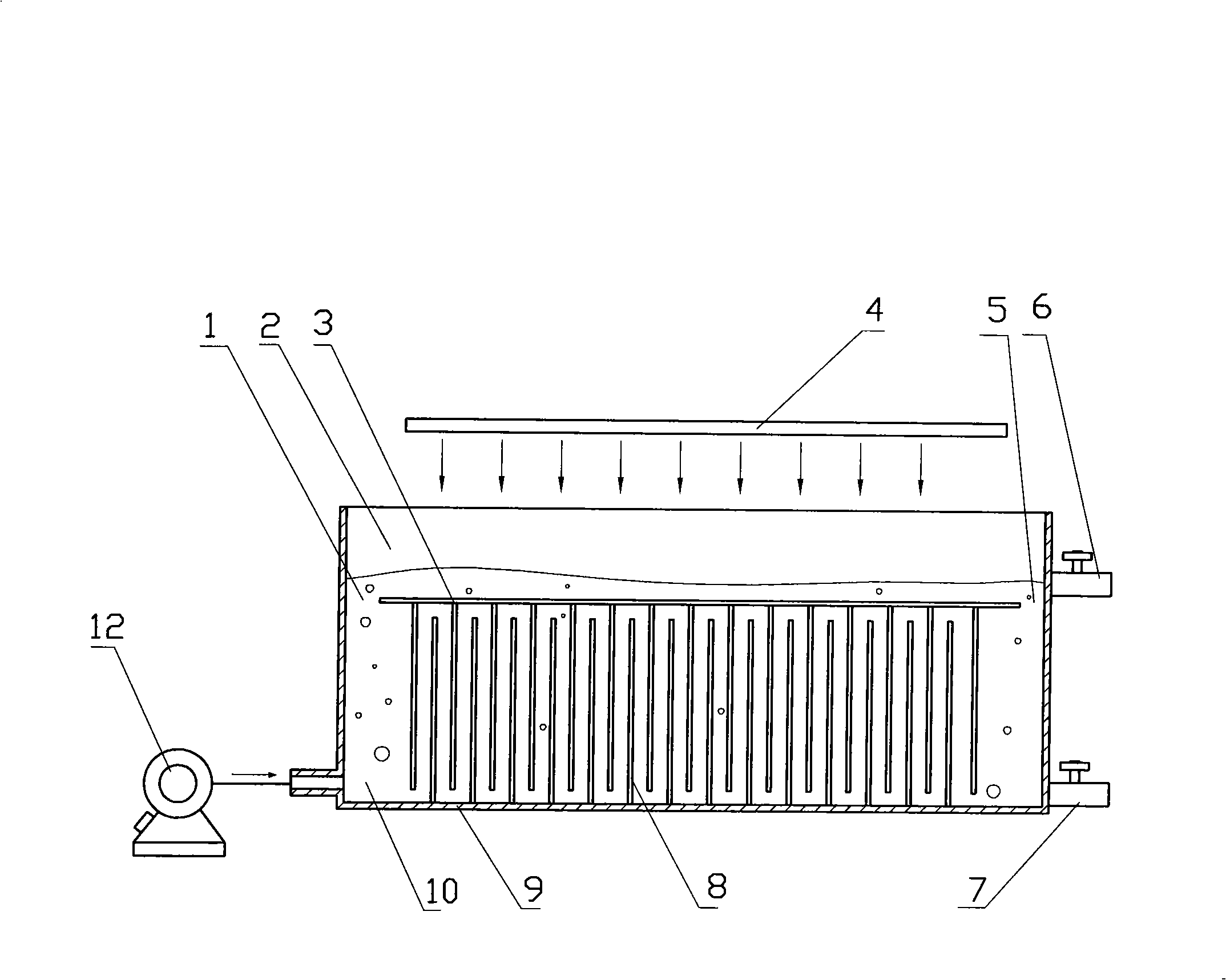

[0039] Coating TiO on the surface of ceramic materials 2 , the fabricated photocatalytic plate 3 is horizontally placed in the reactor 9, and the reactor 9 is divided into an upper photocatalytic zone 2 and a lower biodegradation zone 10.

[0040] Add the domesticated activated sludge solution or the special microbial bacterial solution cultivated for refractory organic wastewater into the reactor 9 and submerge the biofilm carrier 8, and circulate in the reactor 9, turn off the ultraviolet light source 4, and inoculate it through adsorption After 2-3 days, a mature biofilm is formed, and excess activated sludge or bacterial liquid is discharged.

[0041]After the biofilm is formed, continuous treatment is carried out, and another water pump is used to control the flow rate, and the water to be treated is pumped into the reactor to realize continuous treatment. The upper part of the reactor 9, and the wa...

Embodiment 2

[0042] The surface water remediation of embodiment two composite pollution

[0043] Coating TiO on the surface of ceramic or glass materials 2 , the fabricated photocatalytic plate 3 is placed on the upper part of the reactor 9, and the reactor 9 is divided into a photocatalytic zone 2 and a biodegradation zone 10. According to the method described in Example 1, the film-hanging and operation are carried out. After the film-hanging is successful, the complex polluted surface water is continuously pumped in for continuous treatment. The water to be treated is continuously circulated through the photocatalysis under the action of the circulating water pump 11 or the air pump 12. Zone and biological reaction zone, when passing through the photocatalytic zone 2, the water body is under the action of photocatalysis, and the refractory organic pollutants are partially degraded into organic carbon sources that can be effectively used by microorganisms, which promotes the smooth remov...

Embodiment 3

[0044] The treatment of embodiment three source water

[0045] Coating TiO on the surface of ceramic or glass materials 2 , the fabricated photocatalytic plate 3 is placed on the upper part of the reactor 9, and the reactor 9 is divided into a photocatalytic zone 2 and a biodegradation zone 10. Continuously pump the source water to be treated into the reactor 9, turn off the ultraviolet light source 4, and circulate the water in the reactor 9 through the circulating water pump 11 or the air pump 12 under the condition of no ultraviolet irradiation. After 7-14 days, let it naturally form a biofilm on the biofilm carrier 8. After the film is successfully formed, turn on the ultraviolet light source 4 to continuously perform advanced treatment on the source water to remove trace organic pollutants in the water body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com