Spent meal for treating surface of non-ferrous metal and method for preparing same

A surface treatment and non-ferrous metal technology, which is applied in the field of degreasing powder preparation, can solve problems such as unsatisfactory use effect, limited application range, single oil removal, etc., and achieve good removal and cleaning effect, which is beneficial to environmental protection and easy to handle.

Inactive Publication Date: 2008-10-15

JIANGSU DEMEI TECH

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Various degreasing agents currently used for surface treatment of nonferrous metals have unsatisfactory application effects due to their components, content and preparation methods.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

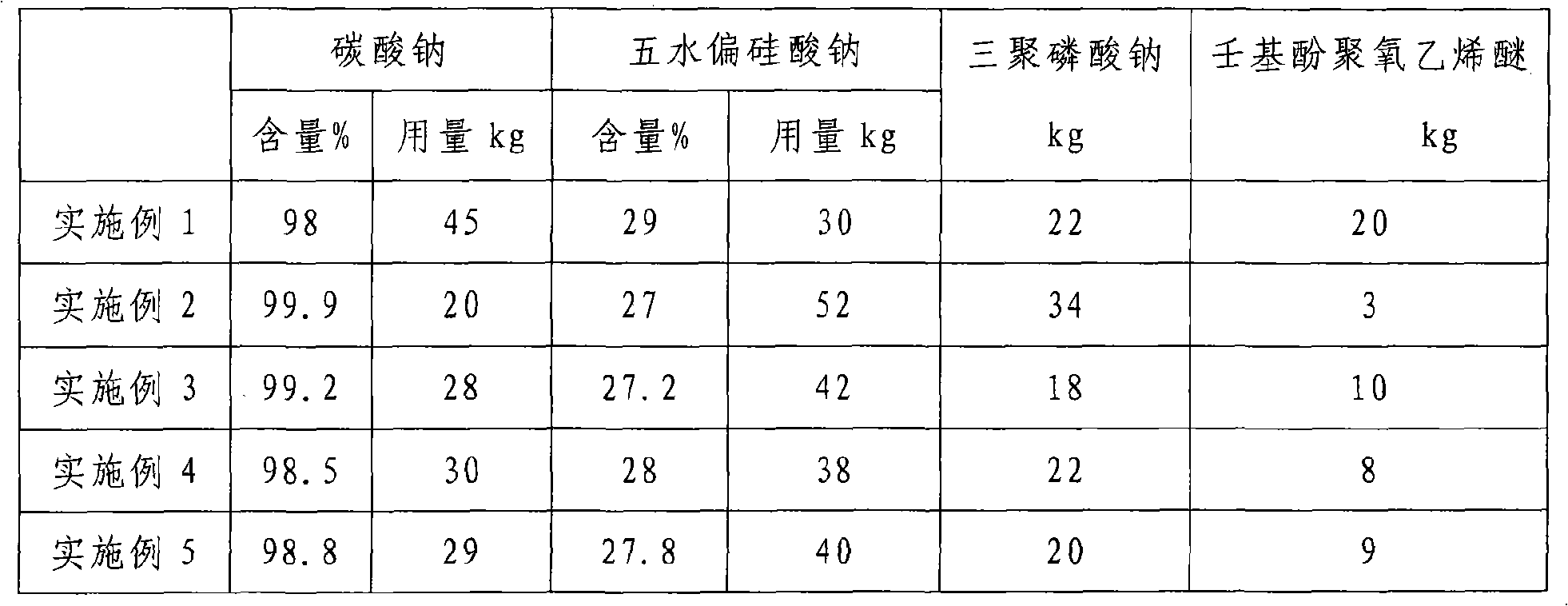

The invention discloses degreasing powder used for surface treatment of nonferrous metals and a method for preparing the same. The compositions by weight portion of the degreasing powder are: 20 to 45 portions of sodium carbonate, 30 to 55 portions of sodium metasilicate pentahydrate, 20 to 35 portions of trimeric sodium phosphate, and 3 to 20 portions of nonyl phenol polyethenoxy ether. The method for preparing the degreasing powder is as follows: firstly, the sodium carbonate and the trimeric sodium phosphate are uniformly mixed and stirred; secondly, the nonyl phenol polyethenoxy ether and the sodium metasilicate pentahydrate are added, and then the finished product is obtained after uniform stirring. The degreasing powder has strong inhabitation ability, is applied to surface treatment of copper, zinc and a plurality of nonferrous metals and alloys of the nonferrous metals, has good cleaning effect on various oil stains such as engine oil, lubricating oil, anticorrosive oil, animal and vegetable oil and so on, and is nontoxic, nonflammable, wide in application range, easy to process waste solution and favorable for environmental protection.

Description

Degreasing powder for non-ferrous metal surface treatment and preparation method thereof technical field The invention relates to a degreasing powder used for degreasing and decontaminating the surface of nonferrous metals and their alloy products, and also relates to a preparation method of the degreasing powder. Background technique In the production of copper, zinc, aluminum, magnesium and other non-ferrous metals and their alloy products, especially in the electroplating production, surface treatment for degreasing and decontamination is often required, which directly affects the electroplating quality of non-ferrous metal products. Various degreasing agents currently used for surface treatment of non-ferrous metals have unsatisfactory effects due to their components, content and preparation methods. They cannot simultaneously inhibit corrosion of various non-ferrous metals, and the degreasing agent is single, and the application range is limited. Contents of the inve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23G1/24C23G5/00

Inventor 瞿德勤

Owner JIANGSU DEMEI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com