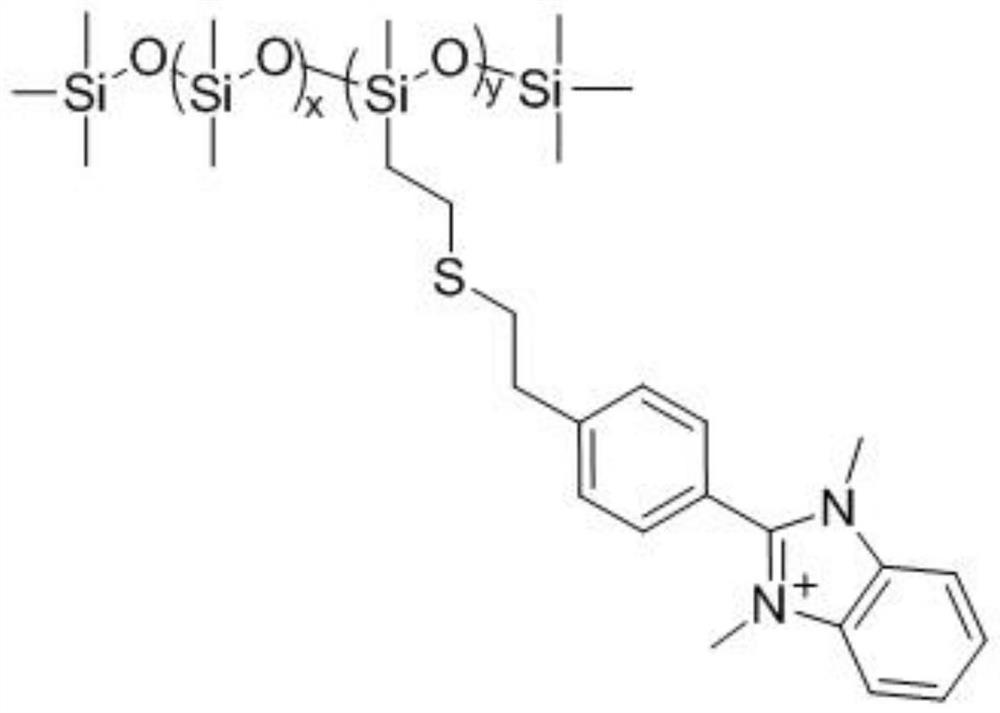

Organosilicon benzimidazole corrosion inhibitor and preparation method thereof

A technology of silicon benzimidazole and benzimidazole, which is applied in the field of silicone benzimidazole corrosion inhibitor and its preparation, can solve the problems of insufficient water solubility, harsh conditions, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of 2-(4-(1-methylbenzimidazol-2-yl)phenyl)ethanethiol (BZHS).

[0039] In a three-necked flask equipped with a water separator and a condenser, add 4-(2-bromoethyl)benzoic acid (25.37g, 0.11mol), N-methyl-1,2-phenylenediamine (16.24g, 0.13mol) and 200mL xylene, fed nitrogen, refluxed acylation reaction at 140°C for 12h, the water separator continuously separated water; continued to heat up to 200°C for cyclization reaction, and ended the reaction after 5h. After distilling off low-boiling substances at 100°C under reduced pressure, recrystallize with acetone, and dry in vacuo to obtain 2-(4-bromoethylphenyl)-1-methylbenzimidazole with a yield of 87.24%.

[0040] Weigh 2-(4-bromoethylphenyl)-1-methylbenzimidazole (14.01g, 0.11mol) and sodium hydrosulfide hydrate (14.83g) into a single-necked flask, add 100mL methanol, and The reaction was stirred for 24 hours, and the reaction solution was filtered and rotary evaporated to dryness at 80°C, 100 mL of dichloro...

Embodiment 2

[0042] Preparation of vinyl silicone oil (PVMS).

[0043] Put D into the single-necked flask according to the feeding ratio 4 V 、D 4 , MM and catalyst tetramethylammonium hydroxide (D 4 mass 0.2%), stirred and reacted at 90°C for 9h, then raised the temperature to 150°C and stirred for 1h to decompose the catalyst at high temperature, and the obtained crude product was distilled under reduced pressure at 150°C to remove raw materials that did not participate in the reaction to obtain PVMS.

[0044] PVMS has the following general molecular structure formula:

[0045] The raw material ratio, molecular structure characterization data and number of each PVMS are shown in Table 1.

[0046] Table 1

[0047]

[0048] The number-average molecular weight (Mn) was measured by a Waters 515-2414 gel permeation chromatograph, the mobile phase was chloroform, the flow rate was 1mL / min, the detector temperature was 35°C, the column temperature was 40°C, and the standard sample was ...

Embodiment 3

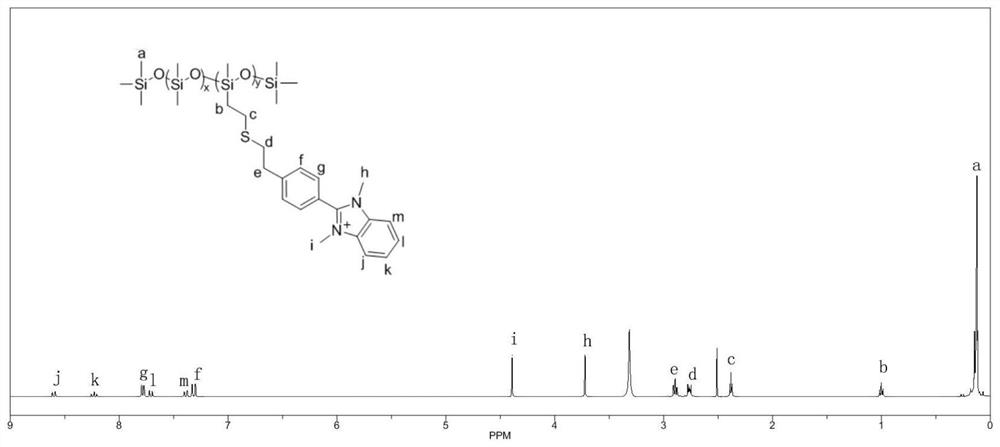

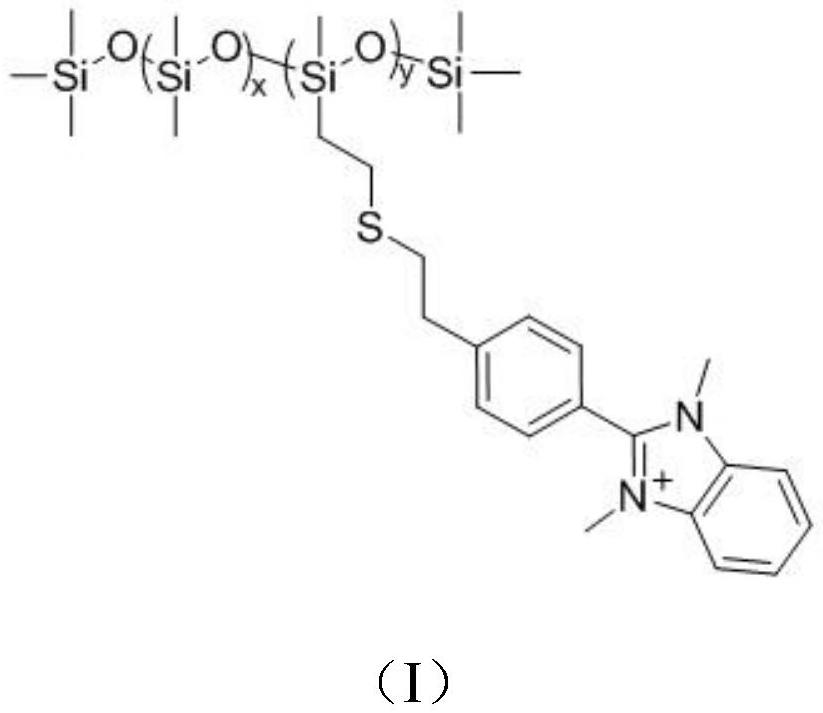

[0053] Preparation of silicone benzimidazole corrosion inhibitor (PDMS-g-BZQA).

[0054]Weigh PVMS, BZHS, benzoin dimethyl ether (DMPA) dissolved in 400mL tetrahydrofuran, and add to the quartz reaction flask, turn on the 365nm ultraviolet light, react at room temperature for 2h under irradiation, finish the reaction, and distill the crude product under reduced pressure Re-dissolved in chloroform, extracted 3 times with a mixed solvent of methanol and water (V:V=1:1), and obtained a light yellow oily substance obtained by volatilizing the organic phase, which was PDMS-g-BZ.

[0055] Put the PDMS-g-BZ obtained above into a reaction bottle equipped with a condenser tube, add methyl iodide and 50mL toluene to dissolve, raise the temperature to 60°C, and keep it under reflux for 48 hours. After the reaction, remove the solvent and methyl iodide by rotary evaporation. The organosilicon benzimidazole corrosion inhibitor (PDMS-g-BZQA) was obtained.

[0056] The raw material dosage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com