Cathode electrodeposition coating method

A technology of cathode deposition and coating method, which is used in the direction of electrolytic coatings, coatings, electro -plating, etc., can solve the problems of complex control technology and cannot control the thickness of the membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

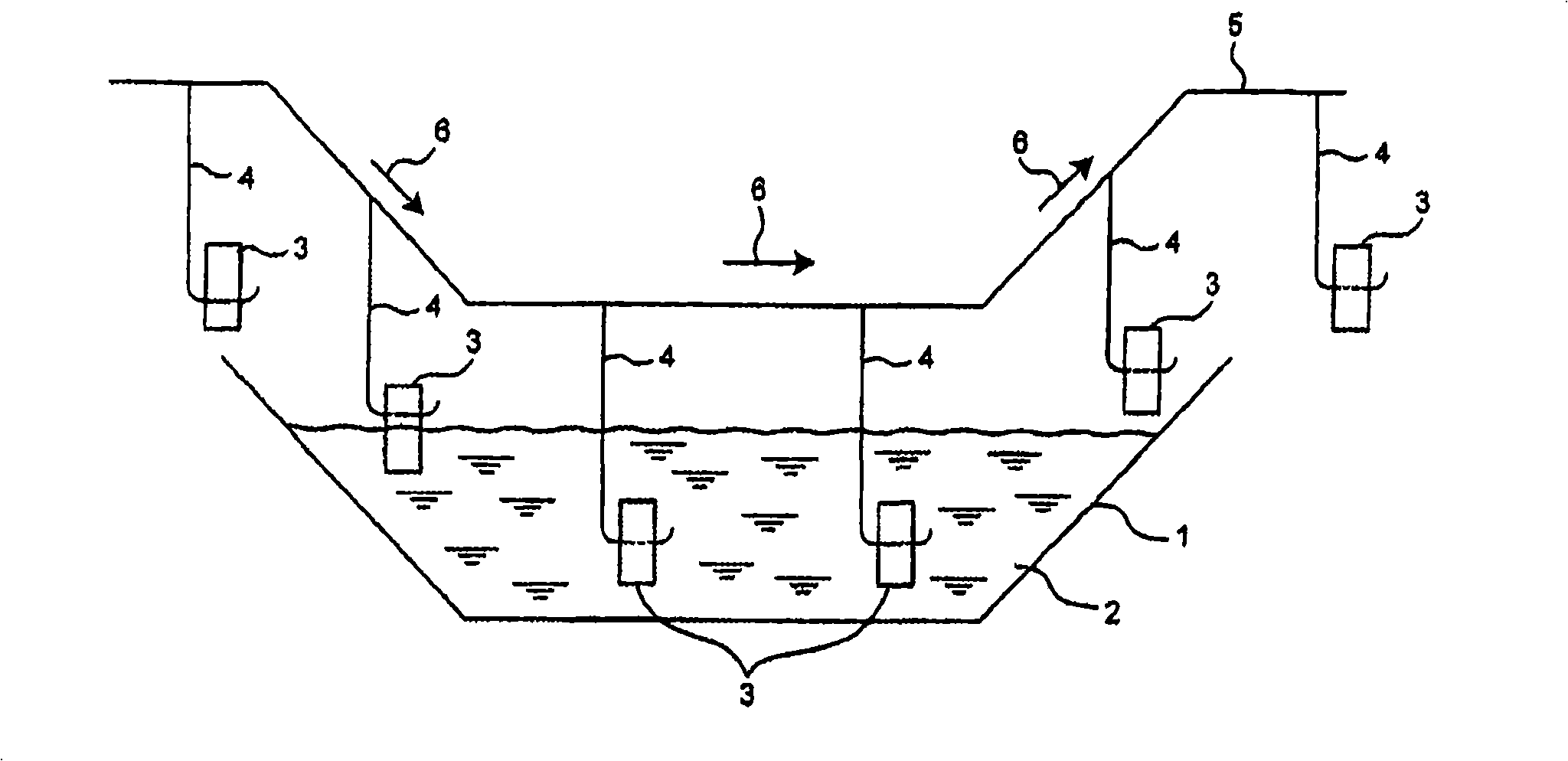

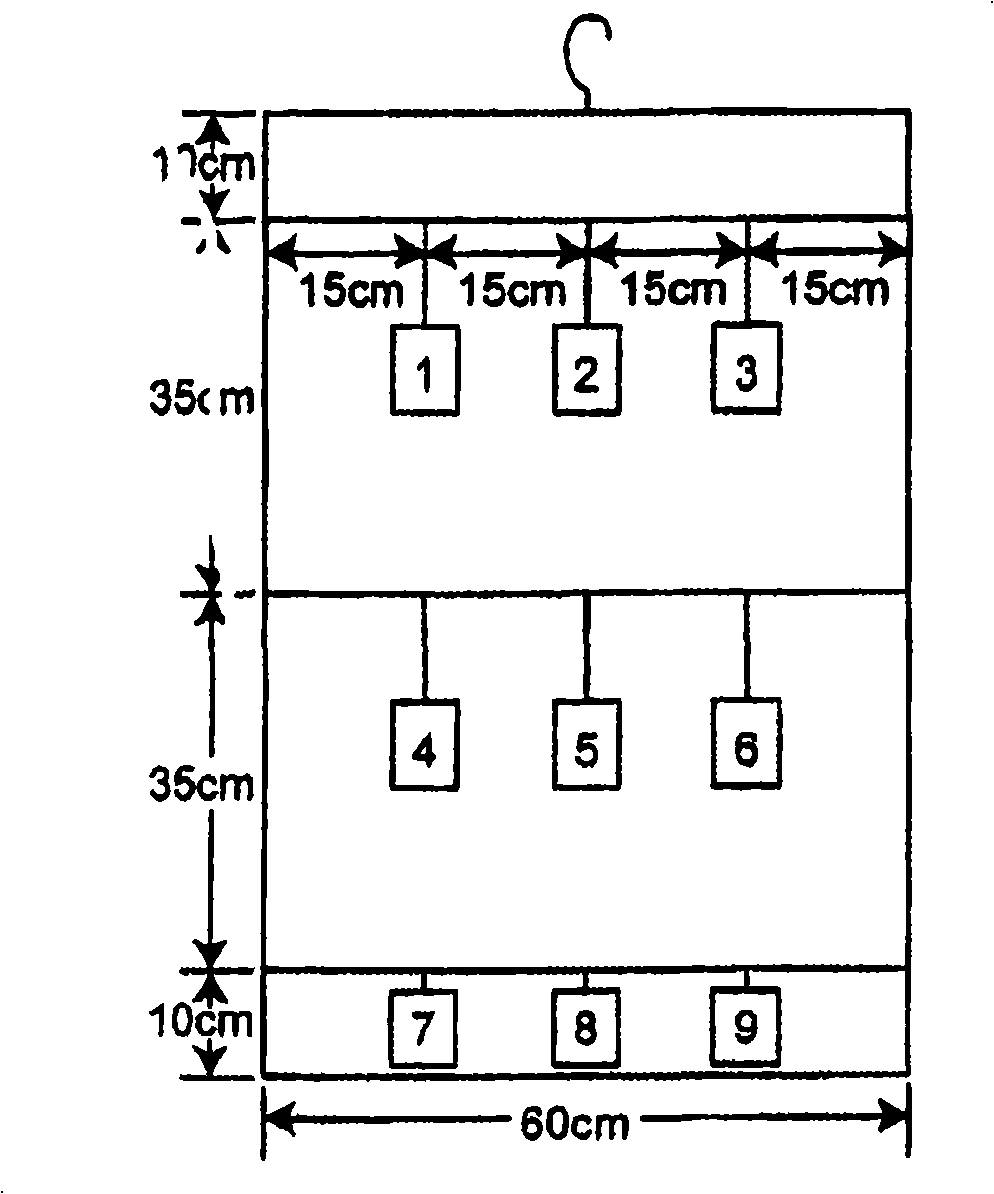

Method used

Image

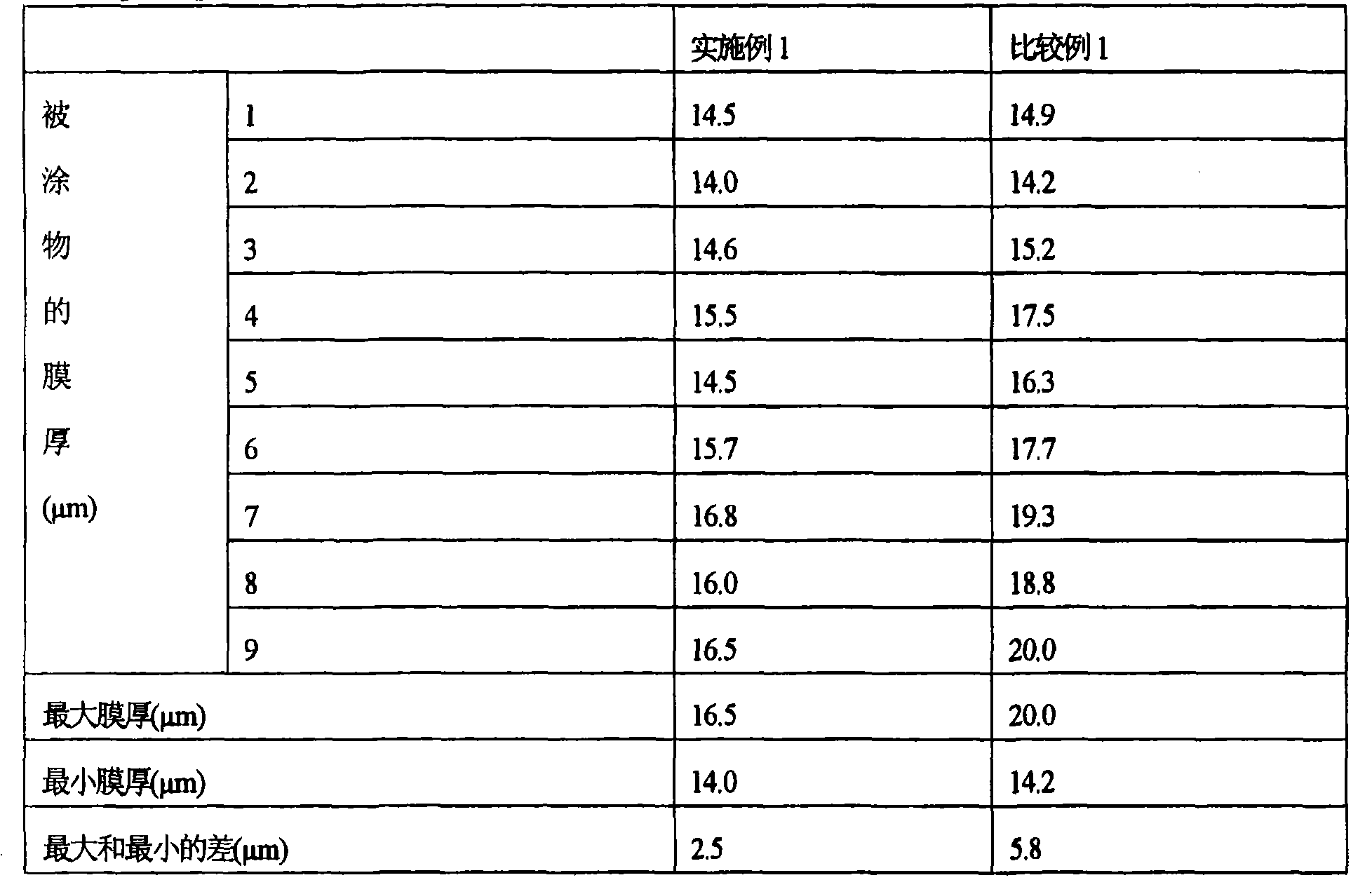

Examples

manufacture example 1

[0100] Manufacture of Blocked Isocyanate Curing Agent

[0101] 1,250 parts of diphenylmethane diisocyanate and 266.4 parts of methyl isobutyl ketone (hereinafter referred to as "MIBK") were added to the reaction vessel, and after heating at 80°C, 2.5 parts of dibutyltin dilaurate were added . Here, the solution in which 226 parts of ε-caprolactams were melt|dissolved in 944 parts of butyl cellosolves was dripped at 80 degreeC for 2 hours. After further heating at 100°C for 4 hours, it was confirmed that the absorption due to the isocyanate group disappeared in the measurement of 1R spectrum, and after natural cooling, 36.1 parts of MIBK were added to obtain a blocked isocyanate curing agent.

manufacture example 2

[0103] Manufacture of Matte Modified Epoxy Resin

[0104] Add 87 parts of 2,4 / 2,6-toluene diisocyanate (mass ratio = 8 / 2), 85 parts of MIBK and dilauric acid di 0.1 parts of butyl tin. While stirring the reaction mixture, 32 parts of methanol were added dropwise. The reaction started at room temperature and was exothermic to 60°C. The reaction proceeds mainly in the range of 60 to 65° C., and the reaction is continued until the absorption due to the isocyanate group disappears in the measurement of 1R spectrum.

[0105] Next, 550 parts of epoxy resins having an epoxy equivalent of 188 synthesized from bisphenol A and epichlorohydrin by a known method were added to the reaction mixture, and the temperature was raised to 125°C. Then, 1.0 parts of benzyldimethylamine was added, and it was made to react at 130 degreeC until the epoxy equivalent became 330.

[0106] Next, after adding 100 parts of bisphenol A and 36 parts of octanoic acid and making it react at 120 degreeC, epo...

manufacture example 3

[0109] Manufacture of Amine Modified Epoxy Resin

[0110] Add 87 parts of 2,4 / 2,6-toluene diisocyanate (mass ratio = 8 / 2), 85 parts of MIBK and dilauric acid di 0.1 parts of butyl tin. While stirring the reaction mixture, 32 parts of methanol were added dropwise. The reaction started at room temperature and was exothermic to 60°C. The reaction proceeds mainly in the range of 60 to 65° C., and the reaction is continued until the absorption due to the isocyanate group disappears in the measurement of the IR spectrum.

[0111] Next, 650 parts of an epoxy resin having an epoxy equivalent of 188 synthesized from bisphenol A and epichlorohydrin by a known method was added to the reaction mixture, and the temperature was raised to 125°C. Then, 1.0 parts of benzyldimethylamine was added, and it was made to react at 130 degreeC until the epoxy equivalent became 300.

[0112] Next, after adding 165 parts of bisphenol A and 29 parts of octanoic acid, and making it react at 120 degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com