Engine system and control method of the engine

A control method and engine technology, applied in the direction of engine control, engine starting, engine components, etc., can solve problems such as engine quality or reliability, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

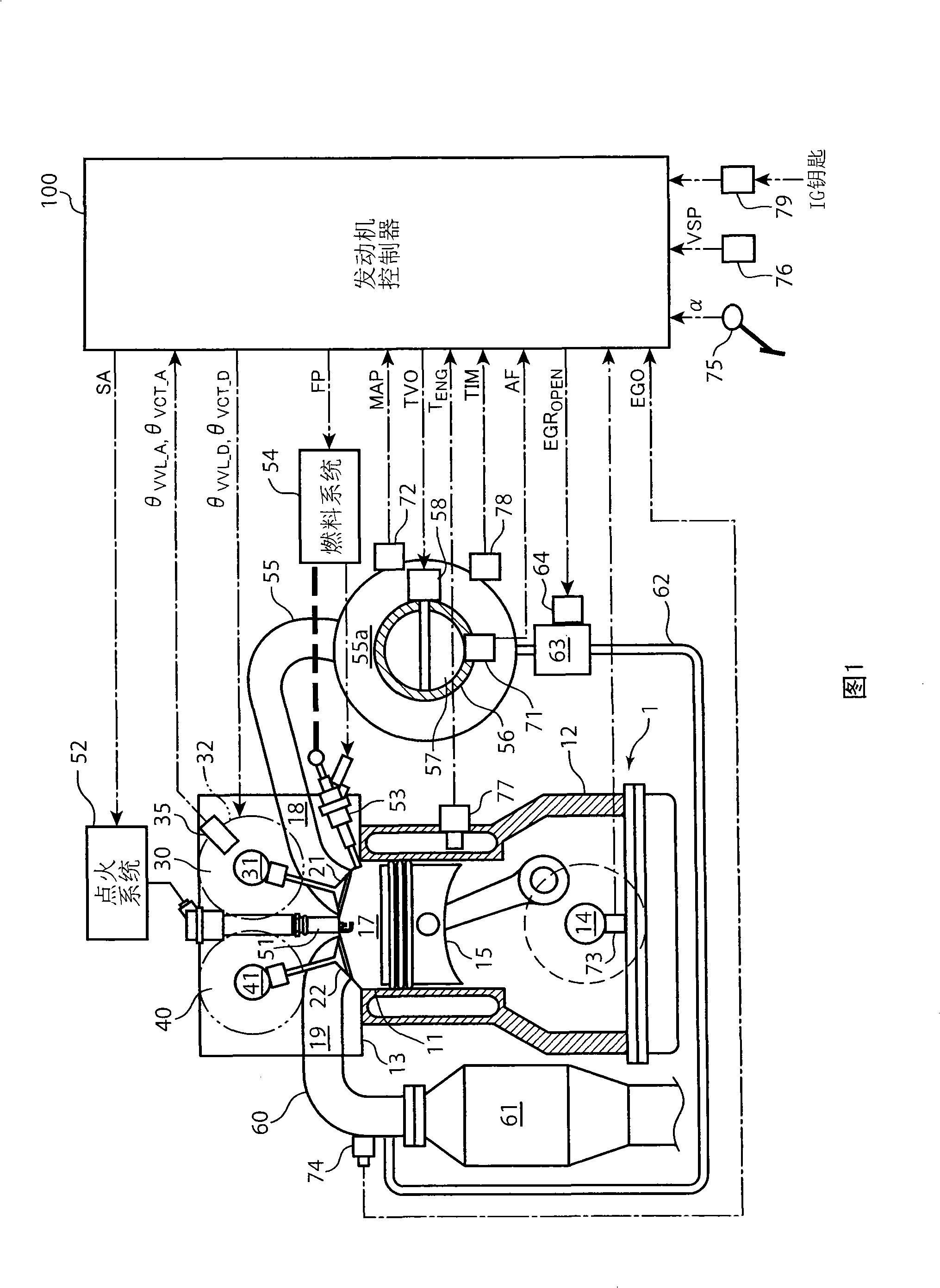

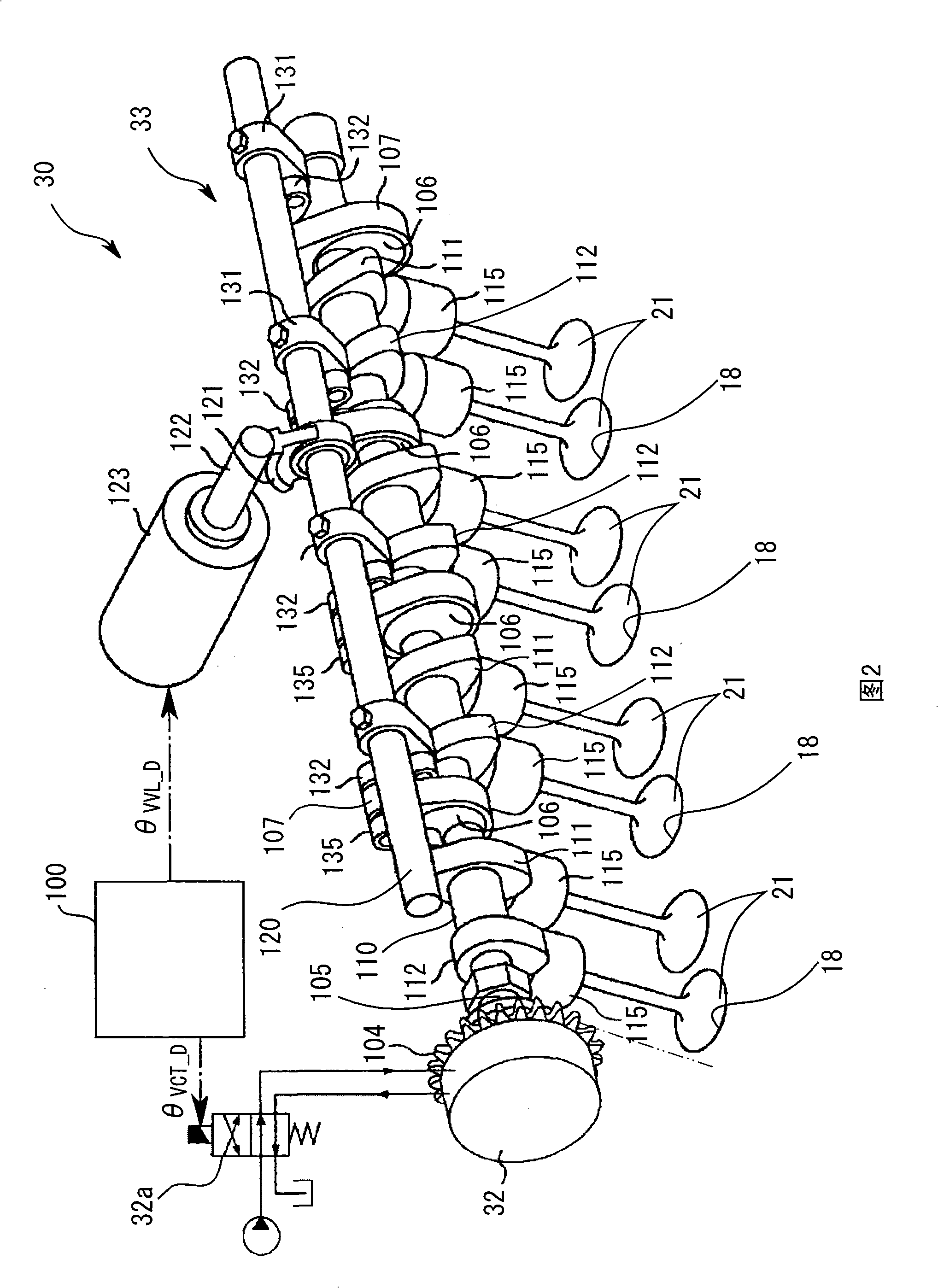

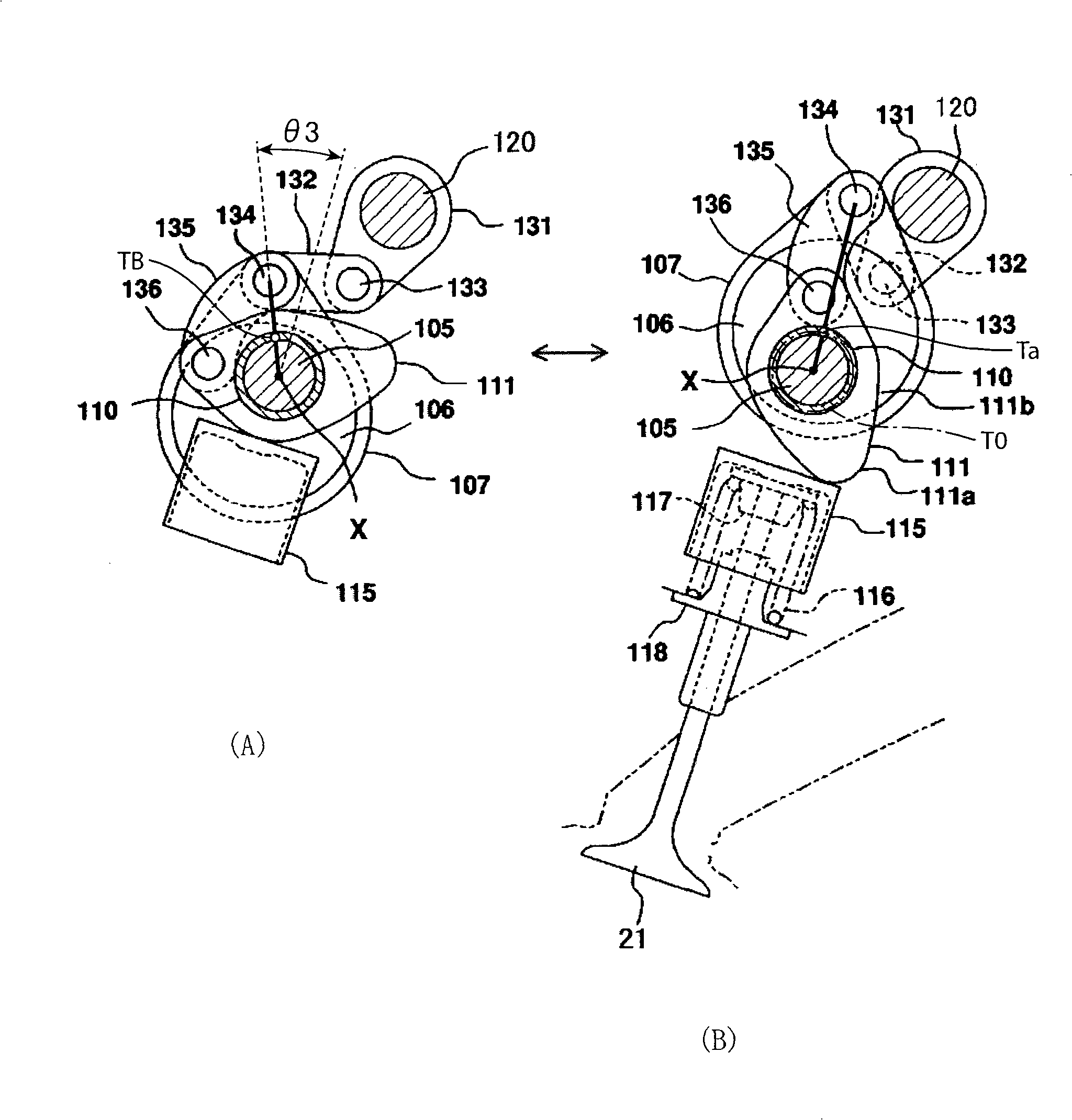

[0045] Fig. 1 schematically shows the overall structure of an engine system to which the present invention is applied. This engine system includes an engine 1 as an internal combustion engine, and an engine controller 100 as a control device for controlling various actuators attached to the engine 1 .

[0046] The engine 1 is a 4-cycle spark ignition internal combustion engine loaded on vehicles such as automobiles, and its output shaft can be connected with the drive wheels through a drive system including a transmission to drive the vehicle. The engine 1 includes a cylinder bank 12 and a cylinder head 13 placed thereon. A plurality of cylinders 11 are formed inside both the cylinder bank 12 and the cylinder head 13 . The engine 1 is, for example, an inline 4-cylinder engine for driving a vehicle, and includes four cylinders 11 . On the other hand, in the cylinder group 11 , the crankshaft 14 is rotatably supported by radial bearings or the like.

[0047] A piston 15 is sl...

no. 2 approach

[0096] Refer below Figure 7 and Figure 8 Control in the second embodiment will be described.

[0097] Figure 7 A routine for overall control of the engine 1 is shown. Initially, the launch control flag F is determined in step S31 发动 Whether the value (initial value: 0) is 1. This determination is set to No, that is, the launch control flag F 发动 When the value is 0, the following control during normal operation is performed.

[0098] First, various signals such as the depression amount α of the accelerator pedal are read (step S32). Next, according to the read accelerator pedal depression amount α, the rotational speed N of the engine 1 ENG (Number of revolutions per unit time, the same below), vehicle speed VSP to calculate the target torque TQ D (step S33), according to the calculated target torque TQ D and engine 1 speed N ENG Calculation of fuel injection amount FP, target air charge amount CE D , and ignition timing SA (step S34).

[0099] Next, according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com