Method for preparing 1,4-di(2,4-diaminophenoxy)benzenoid form self-plasticizing unsaturated polyimides powder

A kind of technology of diaminophenoxy, polyimide powder, applied in 1 field

Inactive Publication Date: 2008-10-22

DONGHUA UNIV +1

View PDF4 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

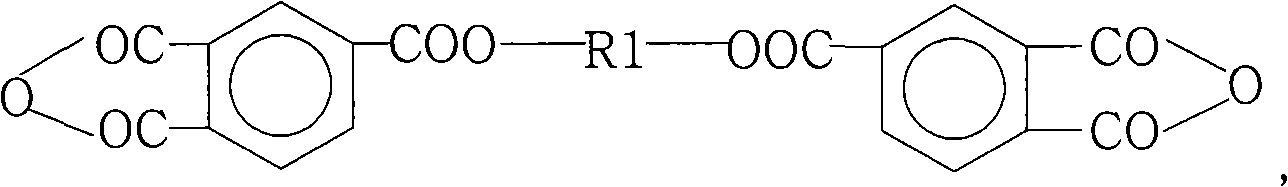

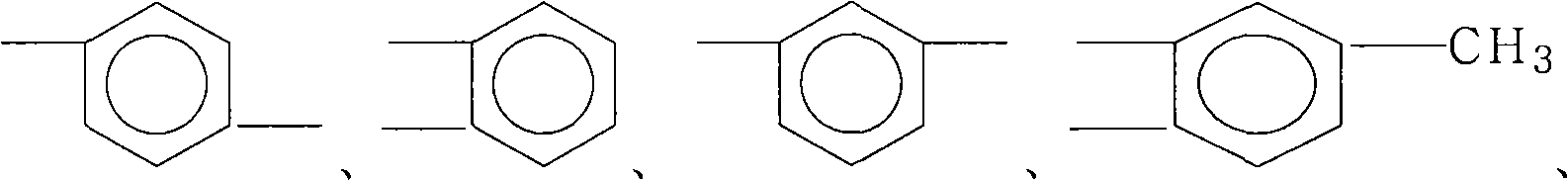

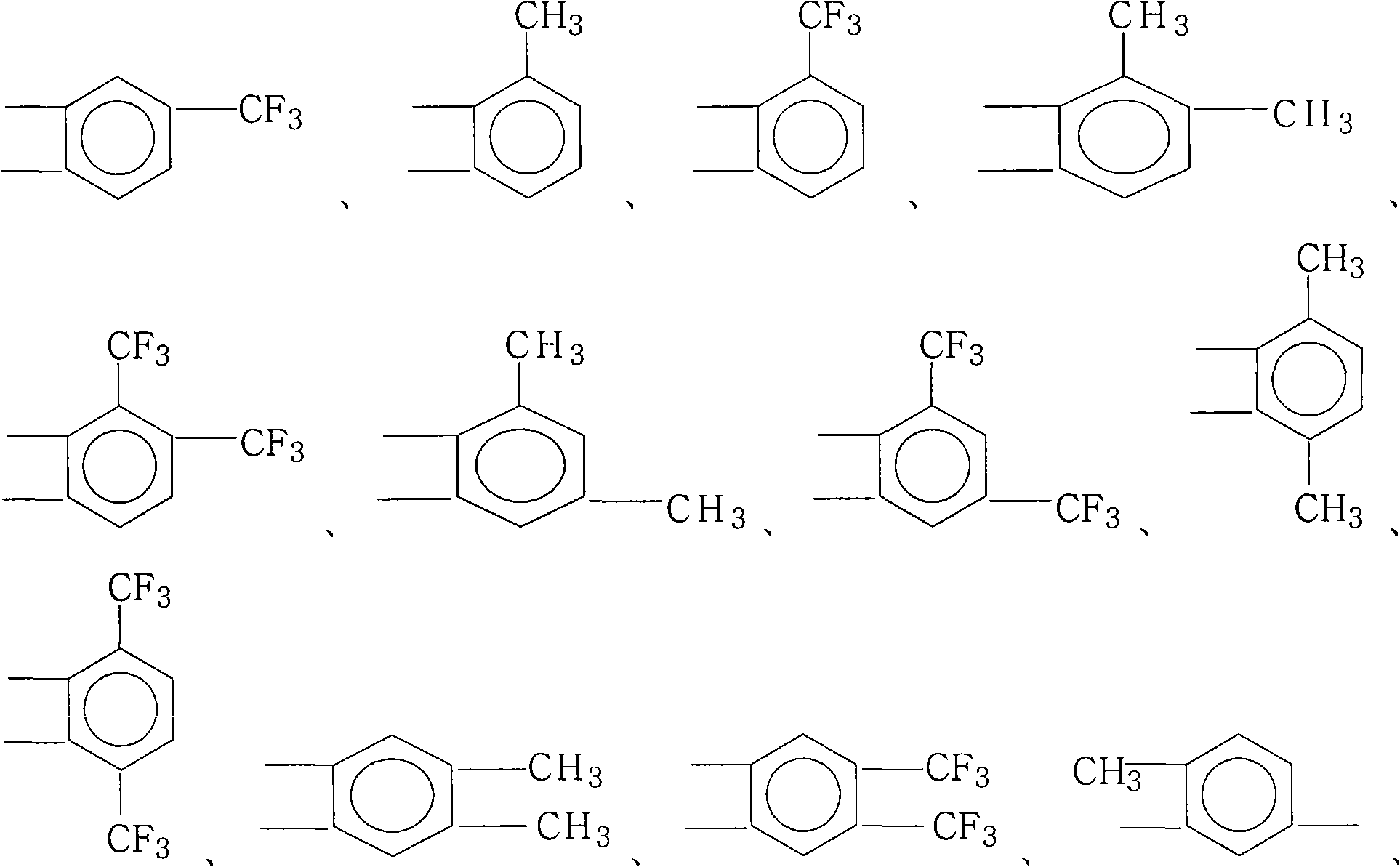

The invention discloses a method for making 1, 4-double (2,4-diamino phenoxy) phenyl type self-toughening unsaturated polyimide powder. The method mainly comprises the following steps that: 1) 1, 4-double (2,4-diamino phenoxy) phenyl, aromatic series binary primary amine and aromatic series binary anhydride as well as an organic compound containing unsaturated double bond are stirred and react in a strong polar aprotic organic solvent system at a temperature of between 20 and 140 DEG C to obtain a brown and ropy thermoset polyamide acid solution capable of cross bonding and curing; 2) the obtained polyamide acid solution is dehydrated, mild-aminated, powdered, filtered, washed and dried to obtain the 1,4-double (2,4-diamino phenoxy) phenyl type self- toughening unsaturated polyimide powder.

Description

1,4-bis(2,4-diaminophenoxy)benzene-type self-reinforced toughness unsaturated polyimide powder preparation method technical field The invention relates to a preparation method of a high-temperature-resistant organic polymer film, in particular to a preparation method of 1,4-bis(2,4-diaminophenoxy)benzene-type self-reinforcing toughness unsaturated polyimide powder. Background technique Polyimide is a class of polymers with excellent comprehensive properties. It has excellent heat resistance, low temperature resistance, solvent resistance, self-lubrication, radiation resistance and flame retardancy. At the same time, it also has very good mechanical and dielectric properties. Therefore, it is widely used in high-temperature and radiation-resistant materials such as spacecraft, satellites or space vehicles; advanced structural composite materials in aerospace, automotive, electromechanical, etc., C-level or 200-level and above electrical insulation materials, resistance Hig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G73/10C08G73/12

Inventor 虞鑫海陈梅芳

Owner DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com