Supersonic reaction plasma spray gun

A plasma and supersonic technology, applied in the field of spraying guns and ion spraying guns, can solve the problems of not realizing the supersonic plasma spraying function, the coating hardness not reaching the expected results, and the lack of reactive plasma spraying equipment, etc., to reduce raw materials. Cost and spraying energy consumption, increase service life and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

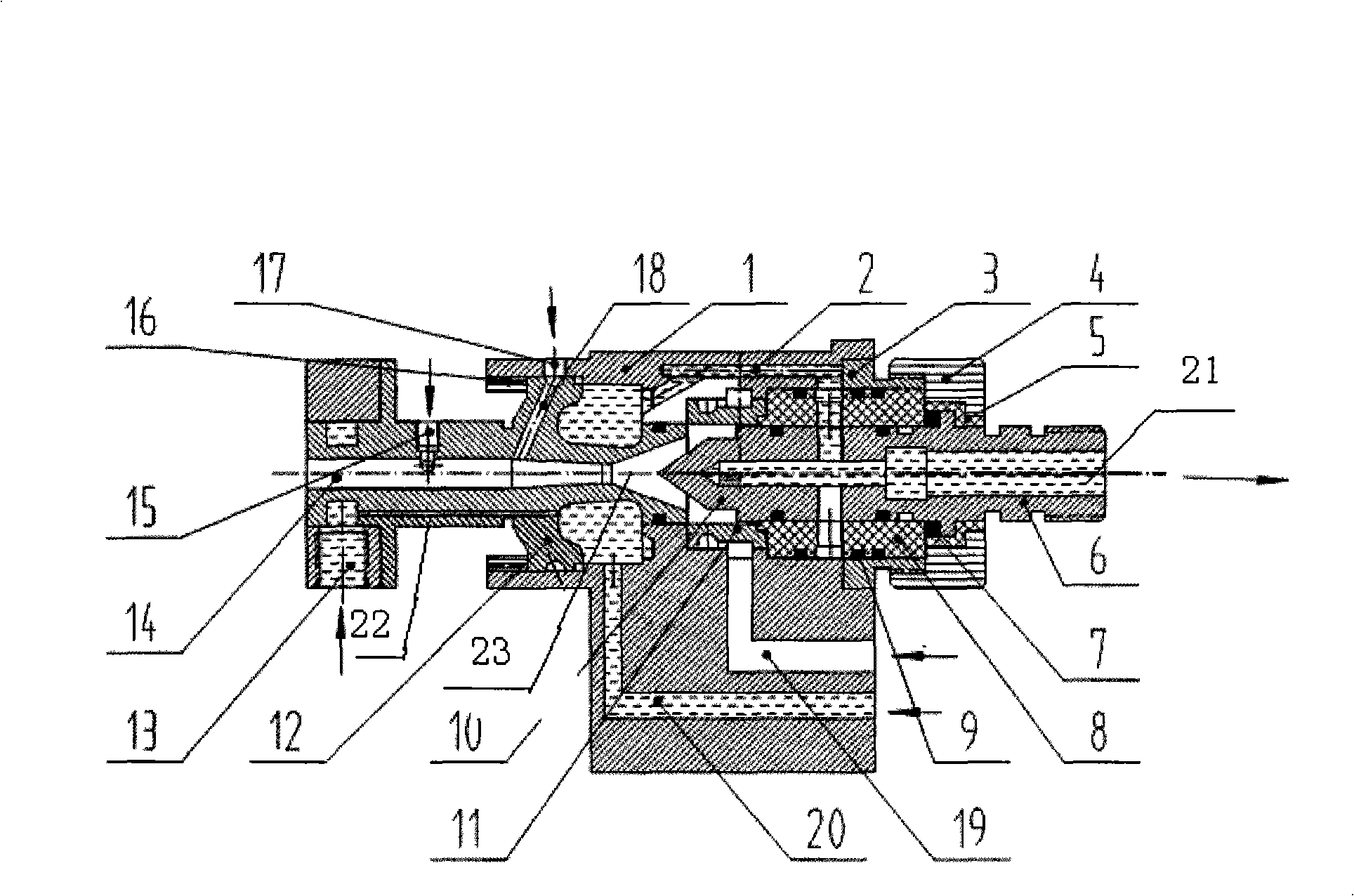

[0011] Such as figure 1 As shown, the present invention includes:

[0012] Including: gun body (1), insulator (8), gas swirl ring (11), cathode body (6), in-situ reaction Laval anode nozzle (12), fastening sleeve (3), front fixing cap ( 16) and back pressure cap (14), insulating spacer (5). Its connection mode: in-situ reaction Laval anode nozzle (12) is connected with the gun body (1) through the front pressure cap (16), and the gas swirl ring (11) and the insulator (8) are fixed through the fastening sleeve (3) Inside the gun body (1), the fastening sleeve (3) is connected with the gun body (1) through tight fit. The cathode body (6) is fixed inside the gun body (1) through an insulator (8), a fastening cap (3), a back pressure cap (14), and an insulating gasket (5).

[0013] The rear portion of the gun body (1) is provided with an ion gas inlet (19) and a water inlet cable inlet (9), and the rear portion of the cathode body (6) is provided with a water outlet cable inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com