Oxygen-entering type two cycle engine

A two-stroke, engine technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of insufficient combustion, reducing effective working stroke, rough work, etc. complete burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

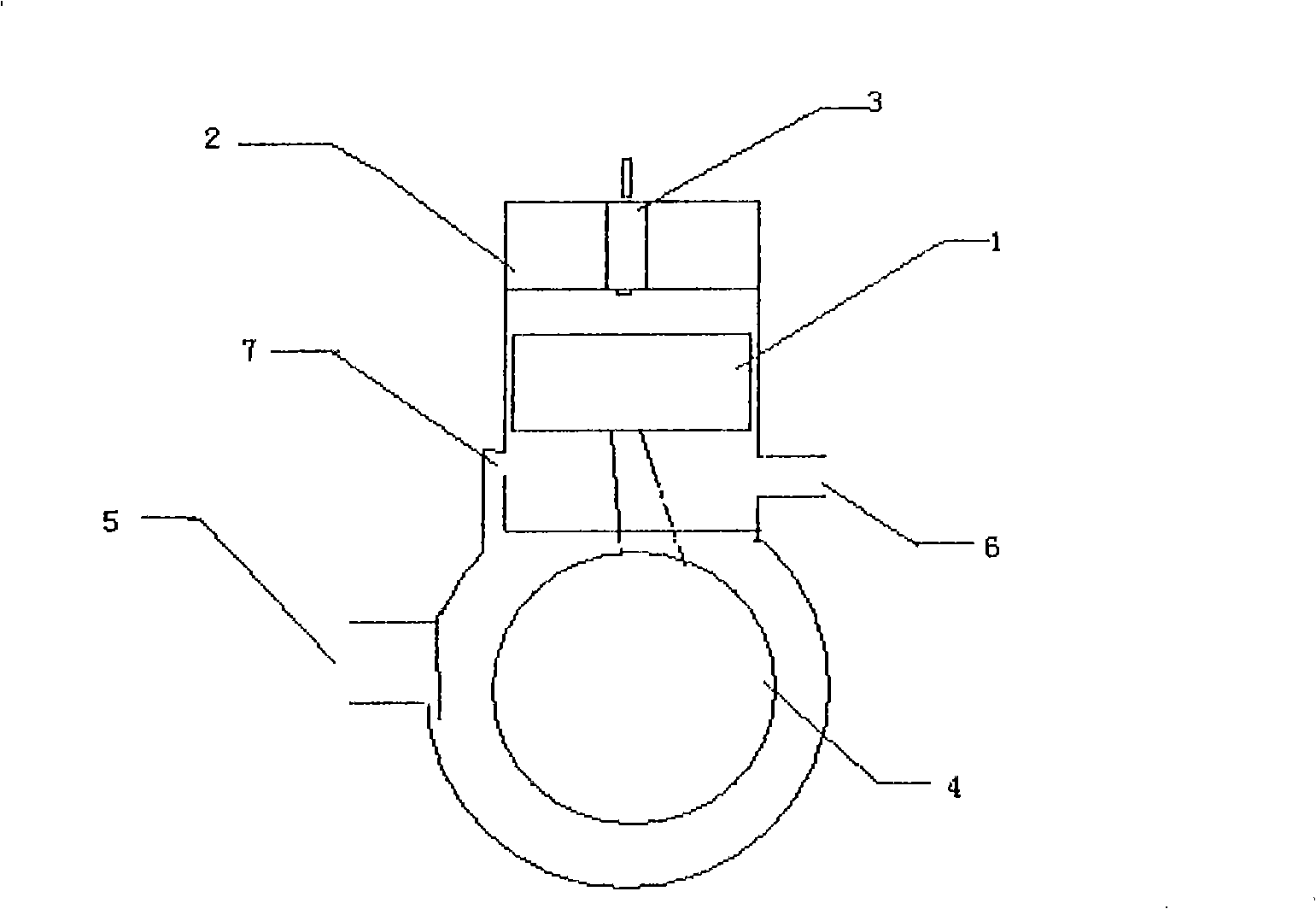

[0025] Such as figure 1 Shown is an existing two-stroke gasoline engine, which includes a cylinder with a piston 1, which divides the cylinder into two chambers, and an exhaust port 6 and a scavenging port 7 are arranged on the cylinder wall at one end of the piston connecting rod. Crankcase is provided with the crankshaft 4 that links to each other with piston rod, and air inlet 5 connects carburetor;

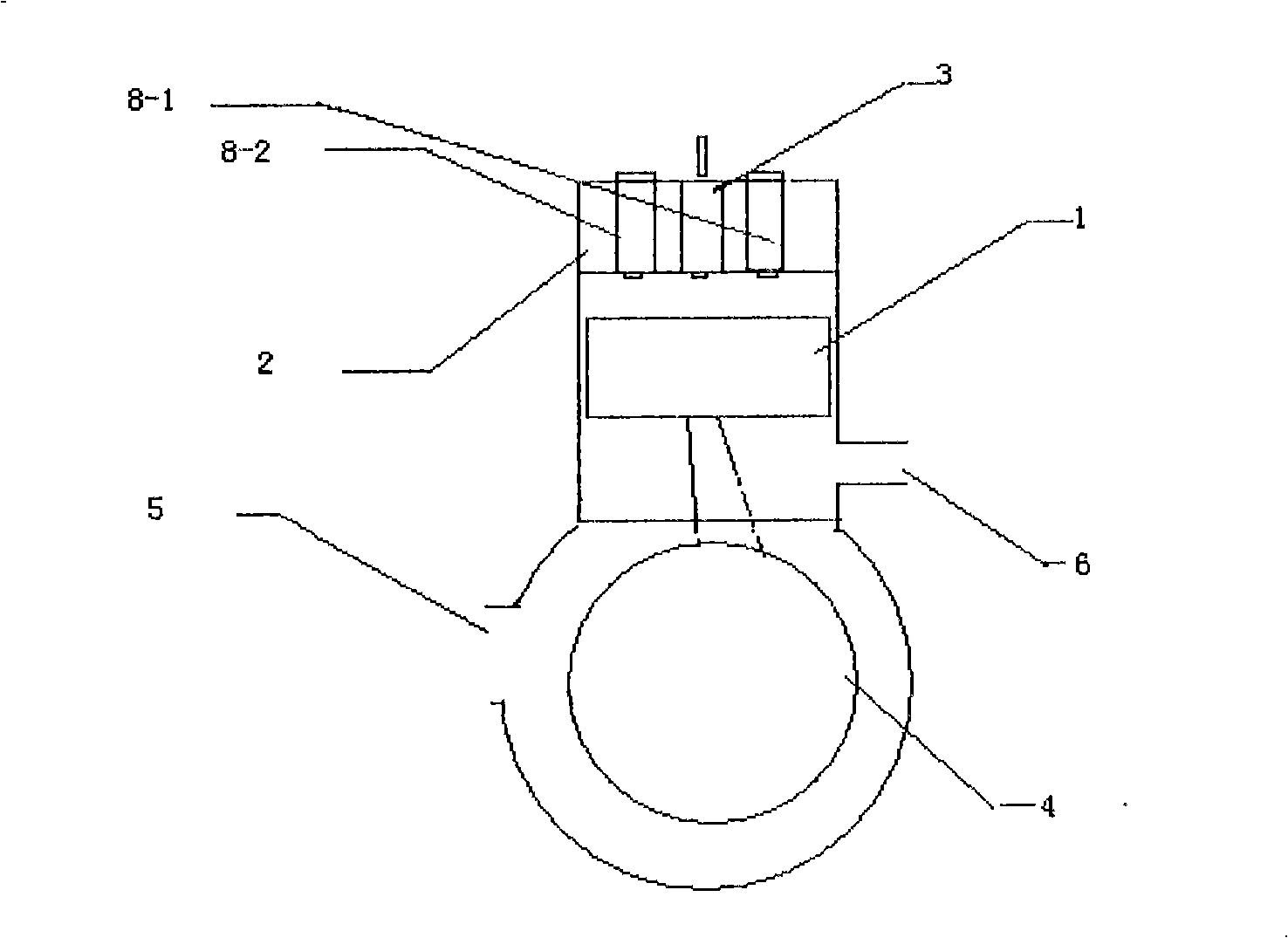

[0026] The oxygen intake type two-stroke engine provided by the present invention is in such as figure 1 The existing two-stroke gasoline engine shown is improved on the basis of that the aforementioned air inlet 5 is changed into a ventilation device, and the scavenging port 7 is canceled or the scavenging port 7 is closed; -1 spray oxygen, and connect one end of a pipeline on the air nozzle 8-1, and connect an oxygen tank on the other end of the pipeline; The oil nozzle 8-2 is connected to an oil pump through a pipeline and then connected to the oil tank. Specifically, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com