Lateral clearance-free double roller enveloped worm transmission device

A technology of worm drive and double rollers, which is applied in transmission devices, gear transmission devices, mechanical equipment, etc., can solve the problems of short precision life, high relative sliding speed, and low transmission efficiency, and achieve easy precision manufacturing and processing and manufacturing , The effect of reducing friction power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure and working principle of the embodiment of the backlash-free double-roller enveloping toroidal worm transmission mechanism of the present invention will be described in detail below in conjunction with the accompanying drawings.

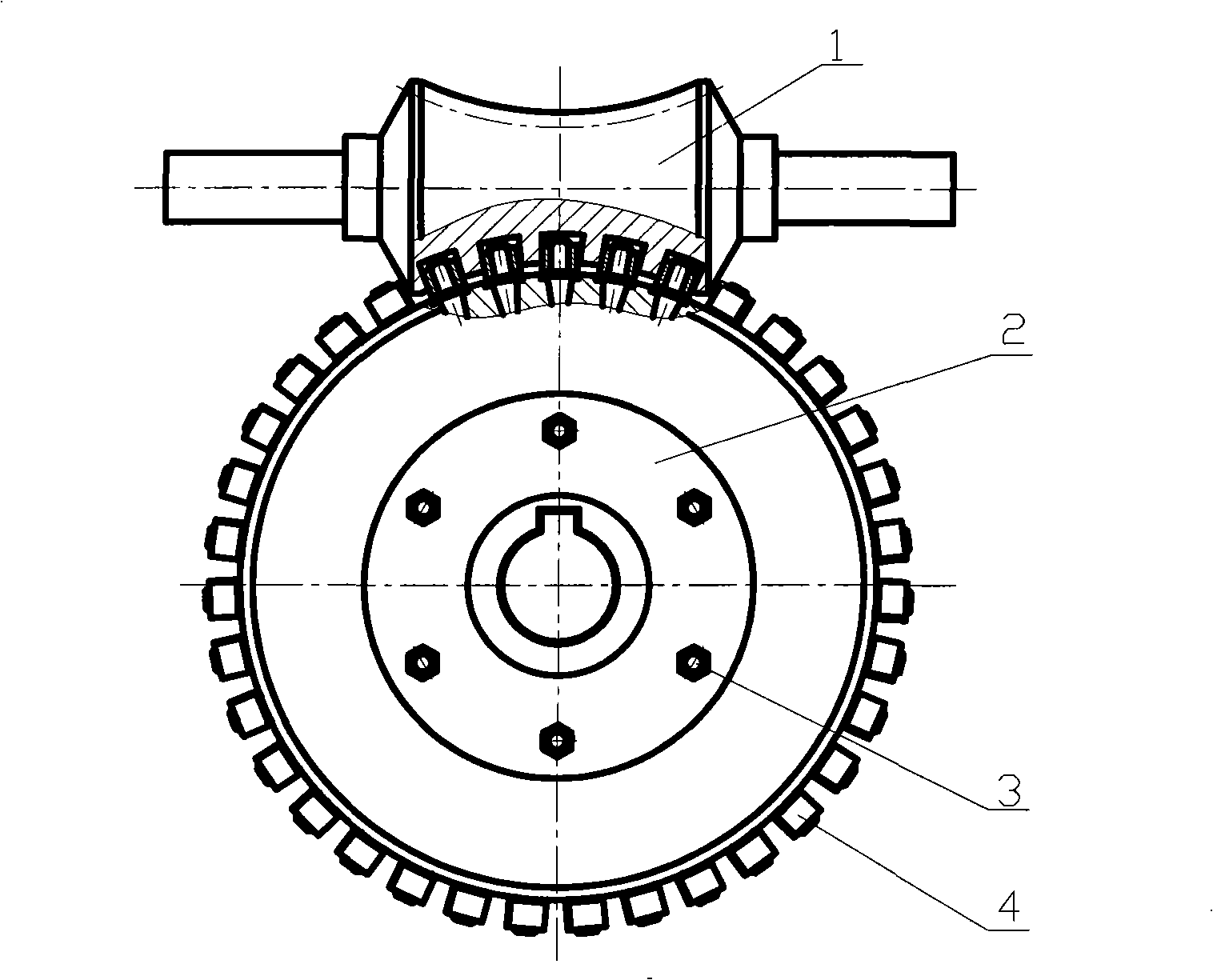

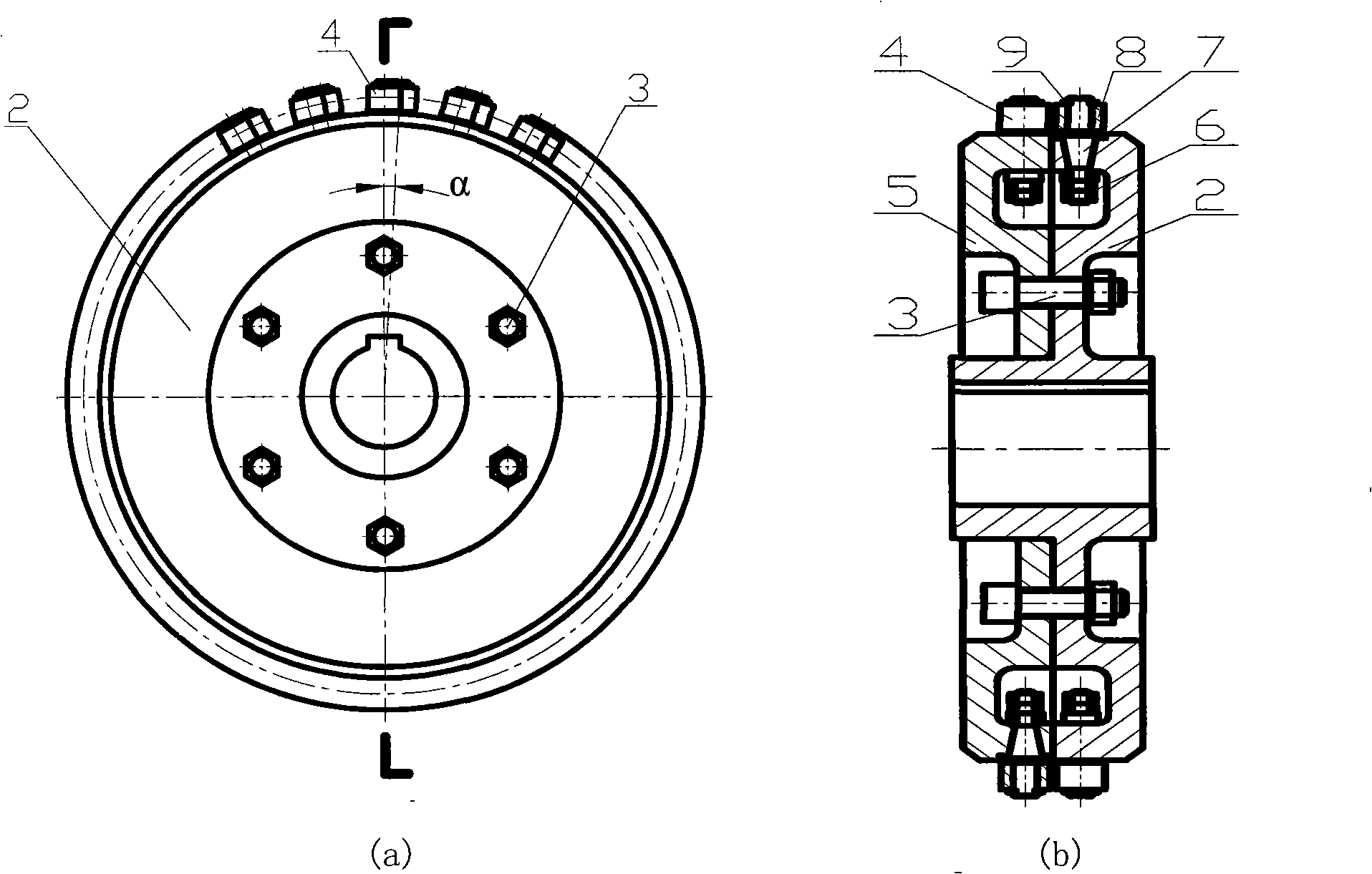

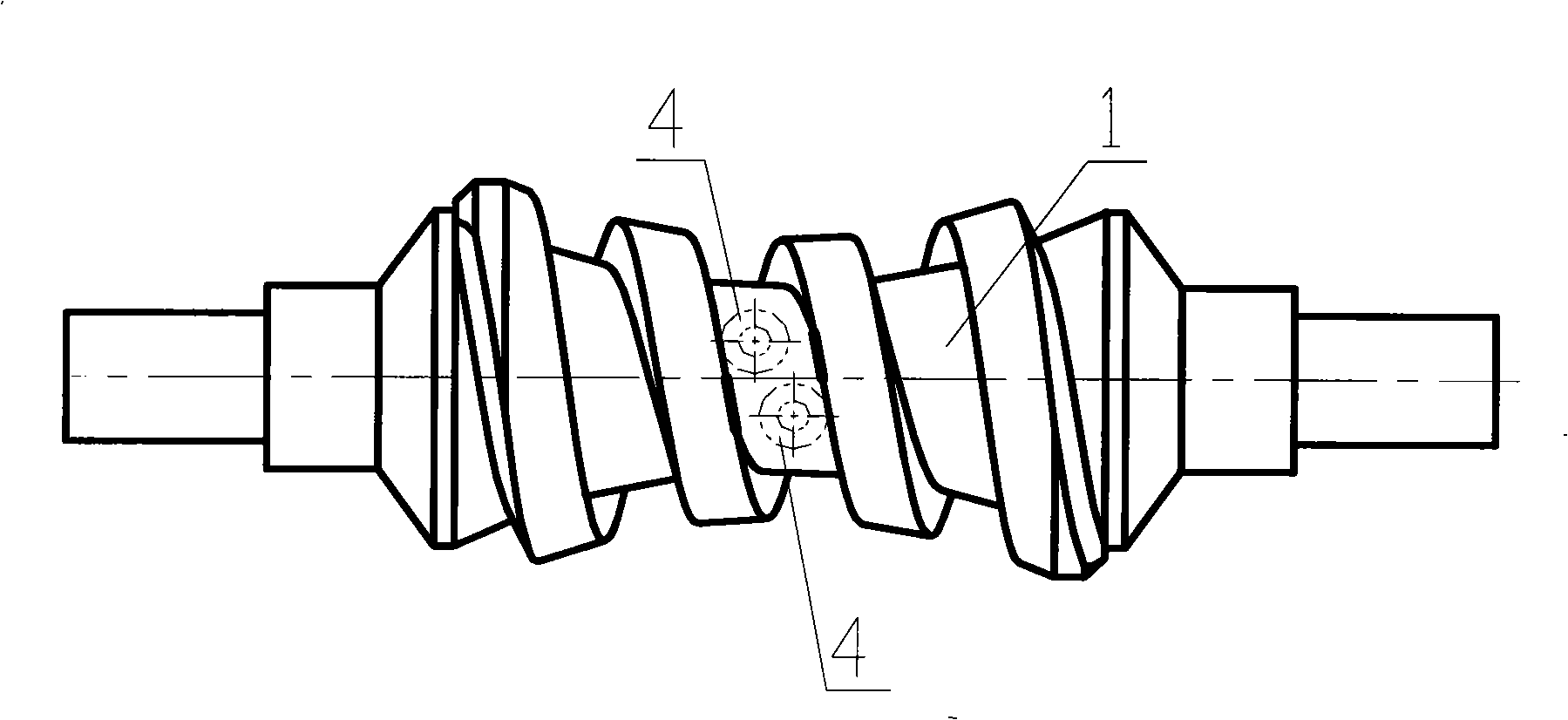

[0025] Such as figure 1 Shown is the worm gear structure diagram of the embodiment of the backlash-free double-roller enveloping toroidal worm drive mechanism. The backlash-free double-roller enveloping toroidal worm transmission mechanism of the present invention is composed of a worm 1 and a worm wheel formed by one-time enveloping with the roller side as the tool mother surface. Such as figure 2 As shown, the worm wheel is composed of a right half-wheel body 2 and a left half-wheel body 5, and cylindrical rollers 4 are uniformly arranged in the radial direction, and the right half-wheel body 2 can rotate along its center of rotation relative to the left half-wheel body 5, The two are misplaced and installed, and are fastene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com