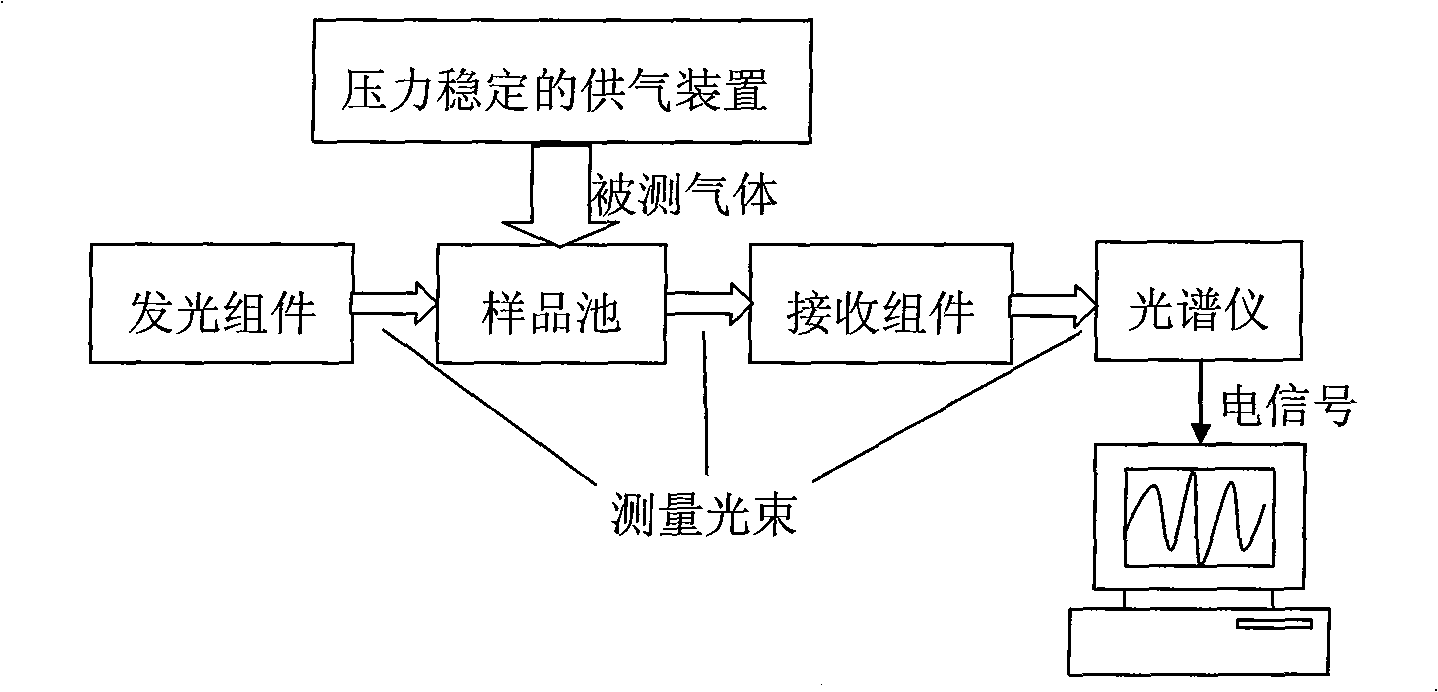

Ultraviolet differential flue gas concentration measuring systems calibration method and enforcement device

A flue gas concentration and measurement system technology, applied in the field of flue gas online monitoring, can solve the problems of few fitting points, high cost, and inability to meet measurement accuracy, and achieve the effects of improving accuracy, reducing cost and operational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

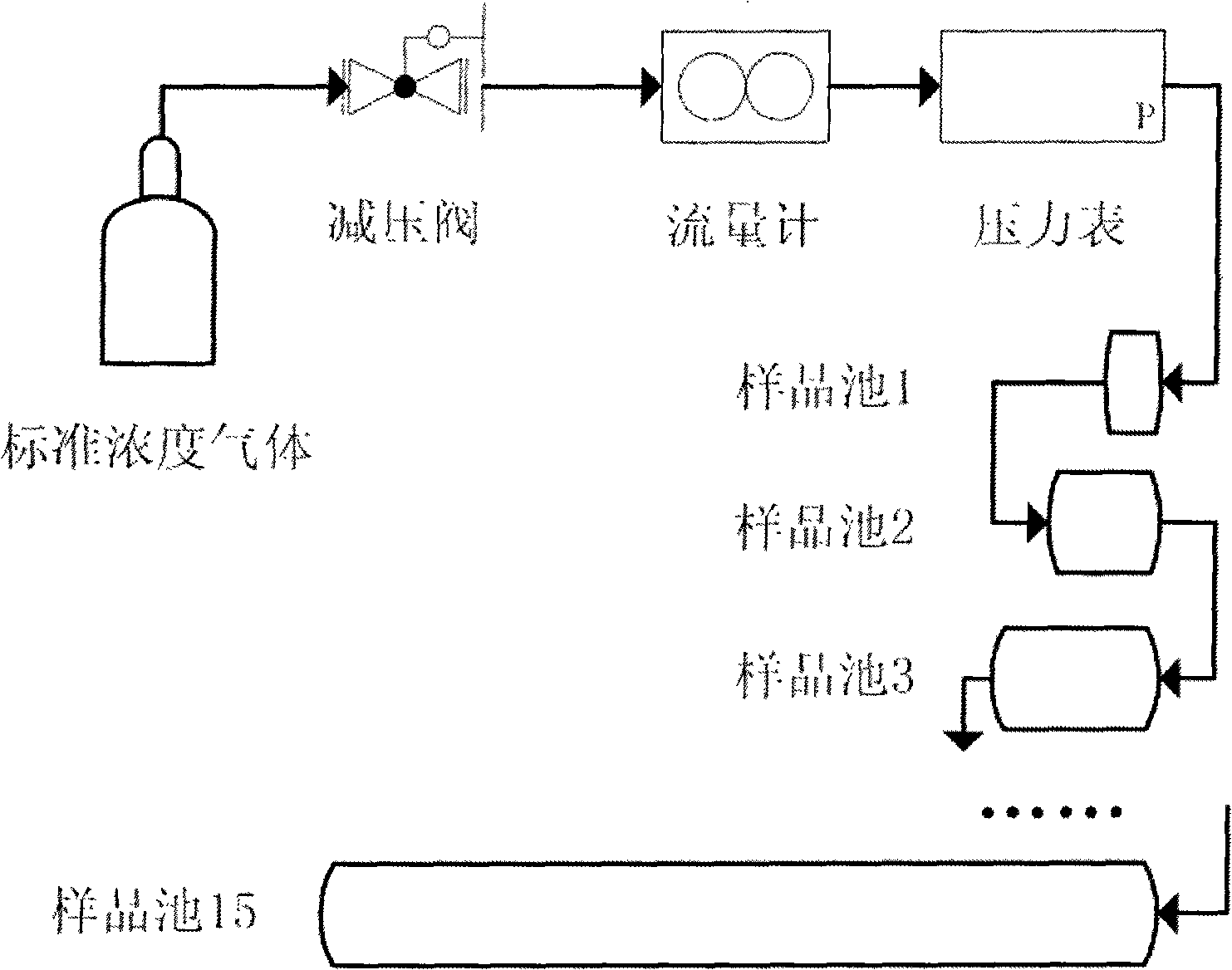

Method used

Image

Examples

Embodiment Construction

[0023] 1. Theoretical Basis

[0024] 1.1 Derivation of the fitting formula

[0025] According to the Lambert-Beer law, the ideal light intensity change after passing through the measured gas can be expressed as:

[0026] A = log I 0 I = K · x · c - - - ( 1 )

[0027] The absorbance A of the measured substance is proportional to the product of the concentration c and the thickness x of the measured substance, and K is a constant of proportionality. Under actual conditions, considering the spectral response characteristics of the spectral acquisition equipment and factors such as gas scattering and absorption, formula (1) can be extended as:

[0028] I d ( λ ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com