Spark generation method and ignition system using same

An ignition system and spark technology, applied in spark ignition controllers, circuits dedicated to spark gaps, spark gaps, etc., can solve the problems of reducing sinusoidal output voltage and complex high-frequency ignition systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the description below, the term "on" is used for a switch when the switch is conducting current, and "off" is used when the switch is not conducting.

[0024] The terms continuous discharge and continuous spark discharge are used herein to mean a continuous spark across the spark gap during the duration of combustion (eg, the combustion stroke of the engine). Successive spark discharges will span multiple, and often many, cycles of energy storage and release of the charge storage device within the ignition circuit.

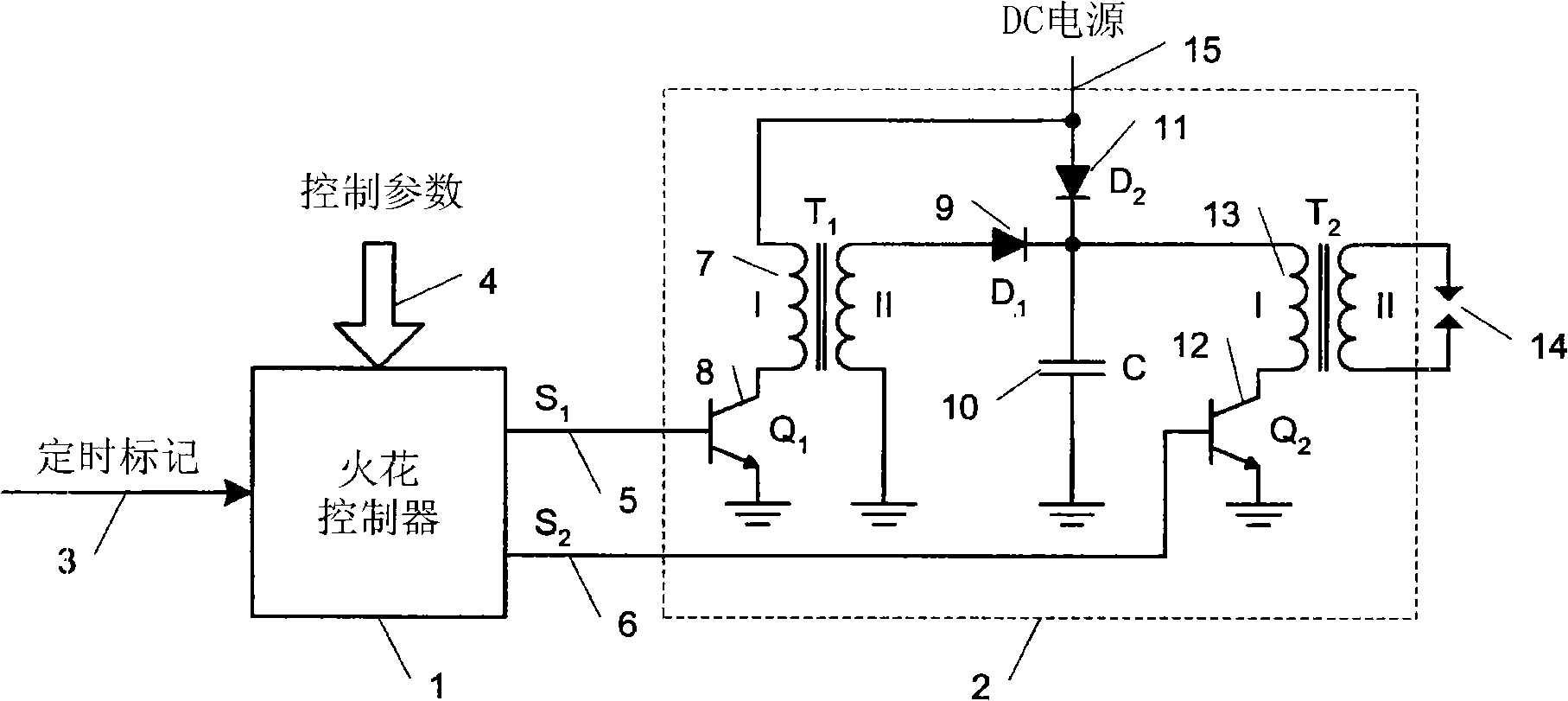

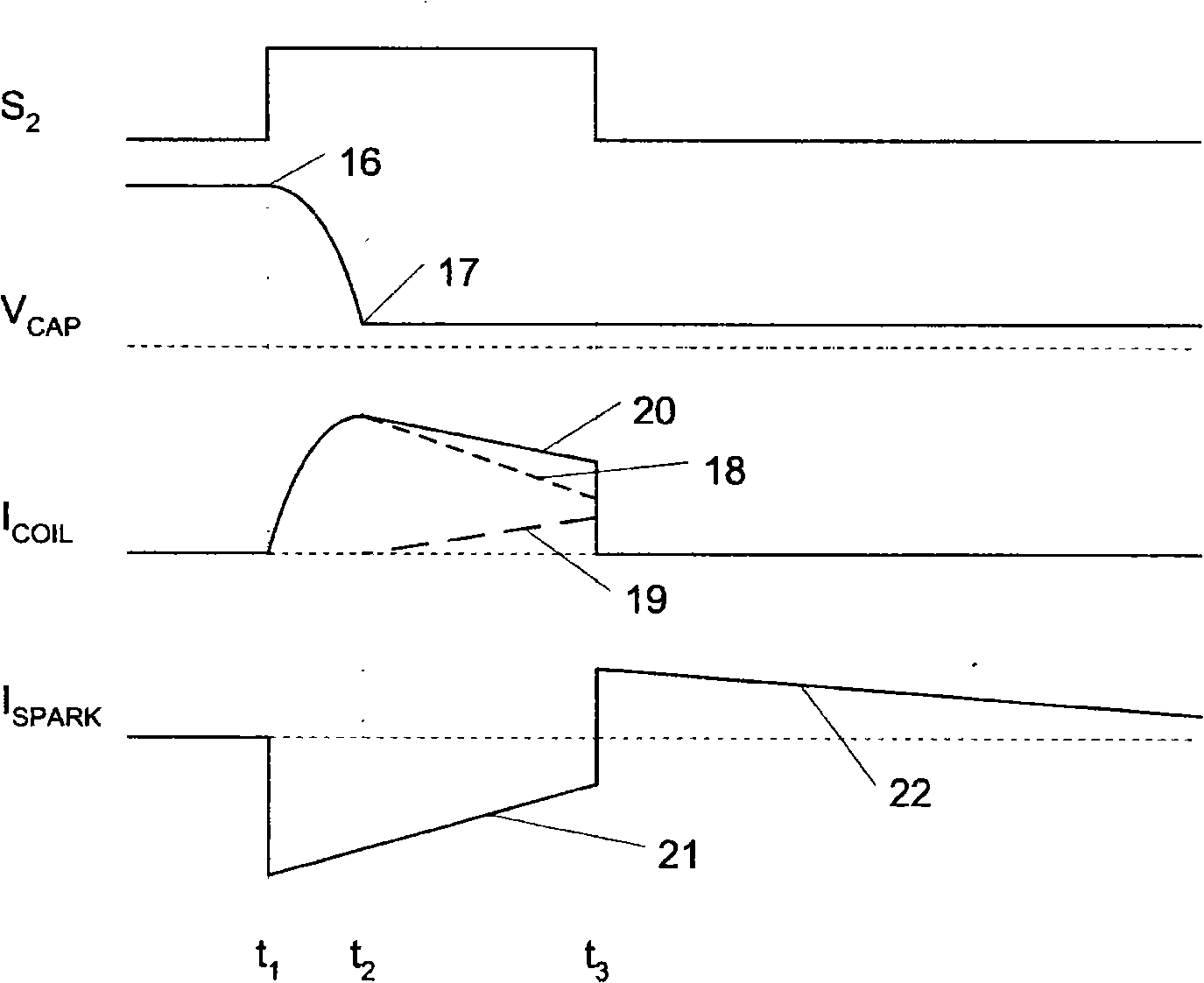

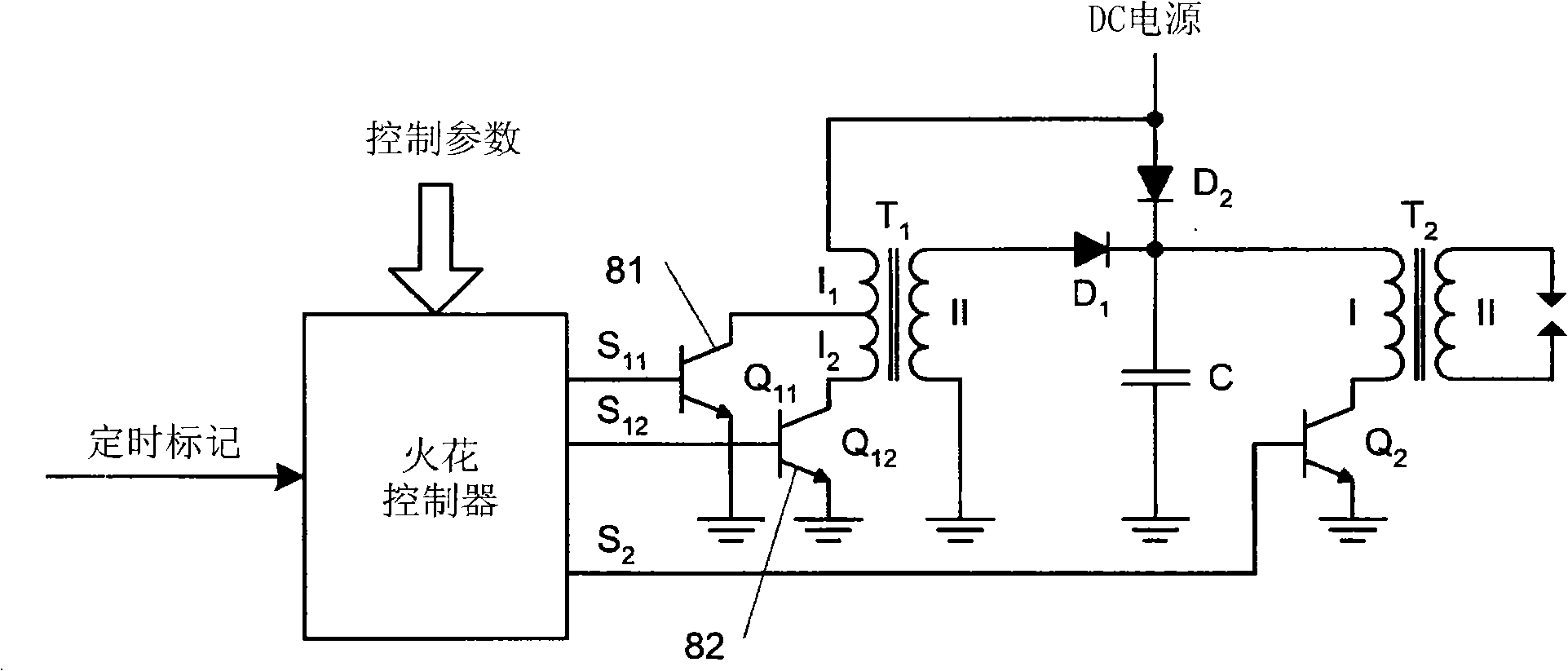

[0025] see figure 1, showing a circuit diagram of an ignition system according to an embodiment of the present invention. The ignition system comprises a spark controller 1 which provides a first control signal along conductor 5 and a second control signal along conductor 6 . Along conductor 5 a first control signal is provided for controlling the storage coil switch 8 and along conductor 6 a second control signal is provided for controlling the igniti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com