Reforming catalyst and preparation method thereof

A reforming catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, naphtha catalytic reforming, etc., to achieve the effect of good activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

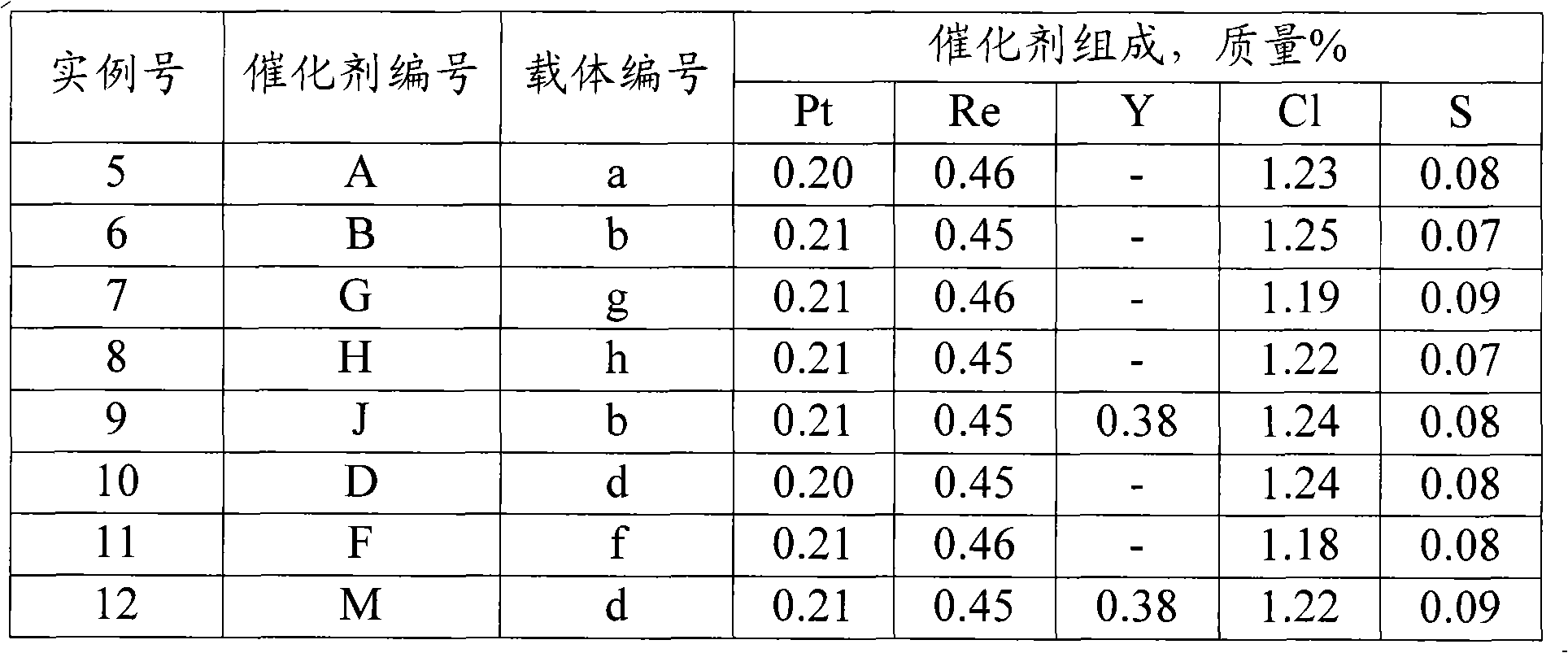

[0018] The preparation method of the catalyst provided by the invention comprises the steps of impregnating the gamma-alumina carrier with a solution containing VIII metals, VIIB metals and halogens, followed by drying and calcining.

[0019] The preparation method of the γ-alumina carrier is as follows: adding a peptizer solution to the hydrated alumina powder, kneading, extruding, drying, and then roasting at 400-750°C. The peptizer solution is a solution containing acetic acid , wherein the content of acetic acid is 20-50% of the mass of dry-based alumina in the hydrated alumina powder.

[0020] The content of acetic acid in the peptizer solution described in the method of the present invention is preferably 24-40% of the dry basis alumina mass in the hydrated alumina powder. The mass ratio of the peptizer solution to the hydrated alumina powder is 0.4 to 2.0:1, preferably 0.6 to 1.0:1, and the amount of the peptizer should not be too much, so as not to completely dilute th...

example 1

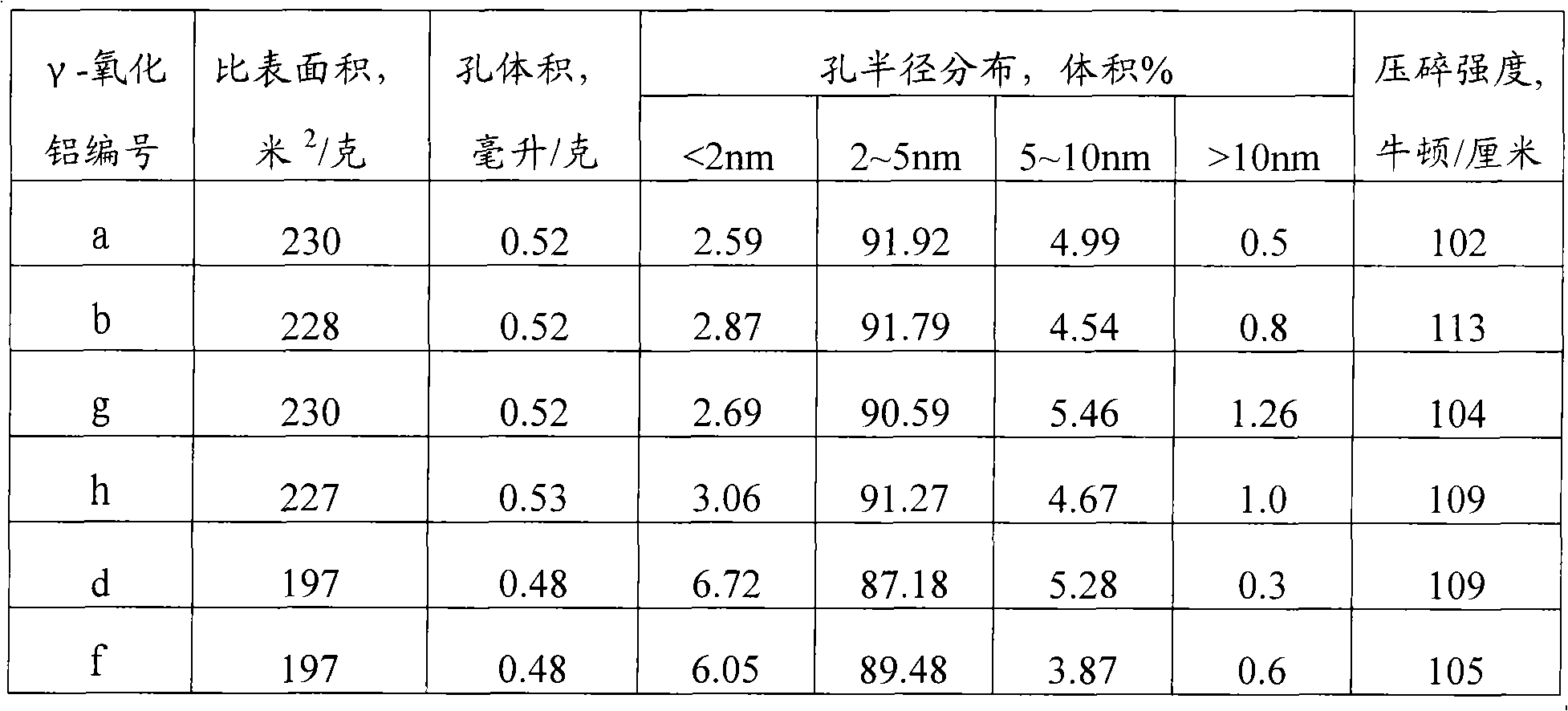

[0034] Add 80 grams of acetic acid solution with a concentration of 36 mass % into 100 grams of pseudo-boehmite powder (SB powder produced by Sasol Company, wherein the alumina content is 75 mass %, the same below) and mix, knead, and then extrude with an extruder Strip molding. The extruded strands were dried at 120°C for 12 hours, cut into 3-6 mm long particles, and calcined at 650°C for 4 hours to obtain γ-alumina a, whose physical and chemical properties are shown in Table 1.

example 2

[0036] Prepare gamma-alumina by the method for example 1, difference is to add the acetic acid solution of 52 grams, and the turmeric powder that contains 4 grams in the pseudo-boehmite powder, the physical and chemical properties of the obtained gamma-alumina b are shown in Table 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com