Process for manufacturing three-dimensional miniature mold

A manufacturing method and miniature technology, which is applied in the field of mold manufacturing, can solve the problems of large mold cavity size, small micro mold depth and width, complex processing technology, etc., and achieve the effects of high precision, low cost and large process flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

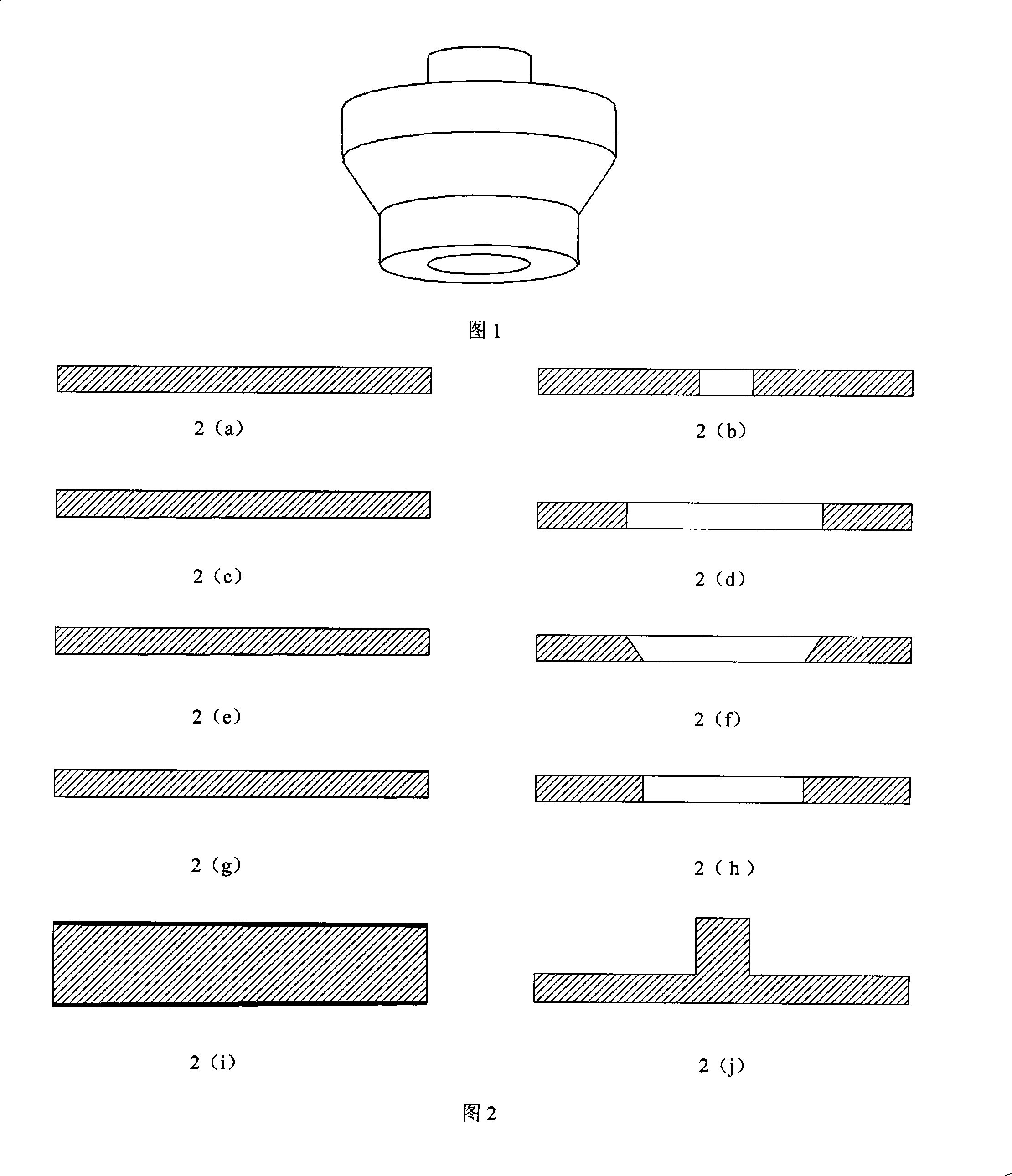

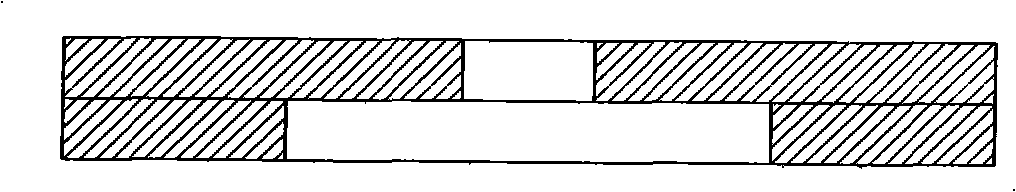

[0023] Fig. 1 shows the three-dimensional micro-parts to be manufactured aimed at the mold made by the present embodiment, the part is divided into 5 layers in the vertical direction, 5 standard silicon wafers are selected, and the silicon wafers are thinned, Fig. 2(a) , Figure 2(c), Figure 2(e) and Figure 2(g) show the thickness of the silicon wafer is 100μm, the thickness of the silicon wafer shown in Figure 2(i) is 300μm, adopt bulk silicon processing technology on the silicon wafer The appearance patterns of each layer of the part are etched in sequence, as shown in Figure 2(b), Figure 2(d), Figure 2(f), Figure 2(h) and Figure 2(j), Figure 2(j) The silicon wafer is etched with the appearance shape of the bottom layer of the part.

[0024] Soak the etched sample to be bonded in the cleaning solution (H 2 SO 4 :H 2 o 2 = 2:1), wash at 120°C for 20 minutes;

[0025] Soak the cleaned silicon wafer in ammonia activation solution (NH 4 OH:H 2 o 2 :H 2 (0=1:1:5) was acti...

Embodiment 2

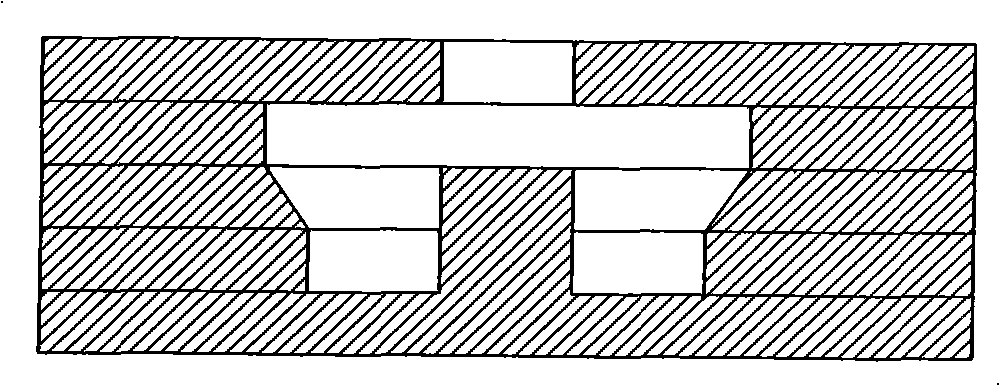

[0030] Figure 5 For the parts that the mold made in this embodiment is aimed at, the mold is divided into three layers, the preparation steps are roughly the same as in Example 1, the difference is: (1) using H 2 SO 4 :H 2 o 2 =4:1 cleaning solution for 15 minutes; (2) using 70% HNO 3 Activation is carried out, the activation time is 20 minutes, and the reaction temperature is 70°C; (3) Lamination is carried out in the order from bottom to top; (4) The annealing time is 10 hours, and the annealing temperature is 450°C. Figure 6 It is a schematic diagram of the cross-sectional effect of the mold manufactured in this embodiment.

Embodiment 3

[0032] Figure 7 The part for which the mold made in this embodiment can be divided into three layers from a structural point of view, but because the two ends of the micro part have a relatively high aspect ratio, when the existing etching technology cannot be etched through, It is divided into two layers, so this part is divided into five layers, the mold preparation steps are roughly the same as in Example 1, the difference is: (1) using H 2 SO 4 :H 2 o 2 = 3:1 cleaning solution, cleaning at 120°C for 10 minutes; (2) using 70% HNO 3 Activation is carried out, the activation time is 20 minutes, and the reaction temperature is 70°C; (3) Lamination is carried out in the order from bottom to top; (4) The annealing time is 8 hours, and the annealing temperature is 500°C. Figure 8 It is a schematic diagram of the cross-sectional effect of the mold manufactured in this embodiment.

[0033] In the specific implementation of the present invention, each silicon chip can be thin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com