Method for producing high-density high-quality iron oxide yellow pigment

An iron oxide yellow, production method technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of high oil absorption, low oil absorption, and high color strength, and achieve reduced usage and oil absorption. Low, high tinting strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

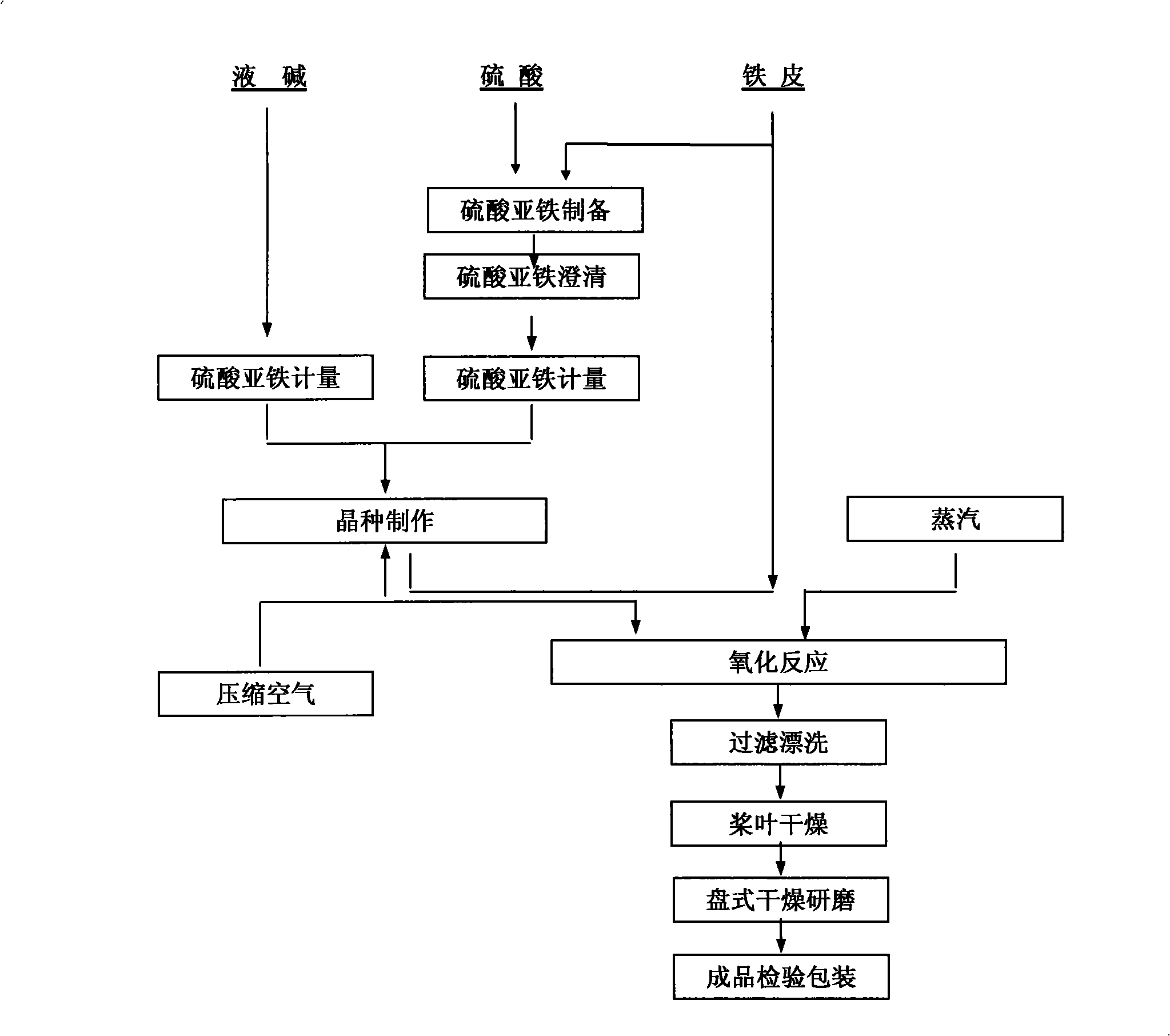

[0021] Such as figure 1 The production method of shown high-density heavy iron oxide yellow pigment comprises the following steps:

[0022] Part 1: Pre-production process

[0023] This part is mainly divided into two steps: seed crystal preparation and oxidation.

[0024] The specific process of seed crystal preparation is as follows: a certain amount of ferrous sulfate is put into the seed crystal reaction tank, reacted with sodium hydroxide solution, and oxidized by passing through air, and finally ferrous hydroxide is oxidized into ferric yellow crystal seeds.

[0025] The specific operation process of oxidation is as follows: fill up the iron sheet in the cleaned bucket, put the prepared crystal seed into the reaction bucket, then add a certain amount of water to dilute, control the content of ferrous iron, and open the steam and air valves at the same time to control Air is blown in to stir the material liquid, and the amount of iron sheet in the barrel is checked and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com