Heat-collecting tube with solar energy selective absorption coating and manufacturing method thereof

A technology of absorbing coatings and manufacturing methods, applied in solar thermal power generation, solar thermal devices, coatings, etc., can solve problems such as poor stability, complicated manufacturing process, and inapplicability, and achieve stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

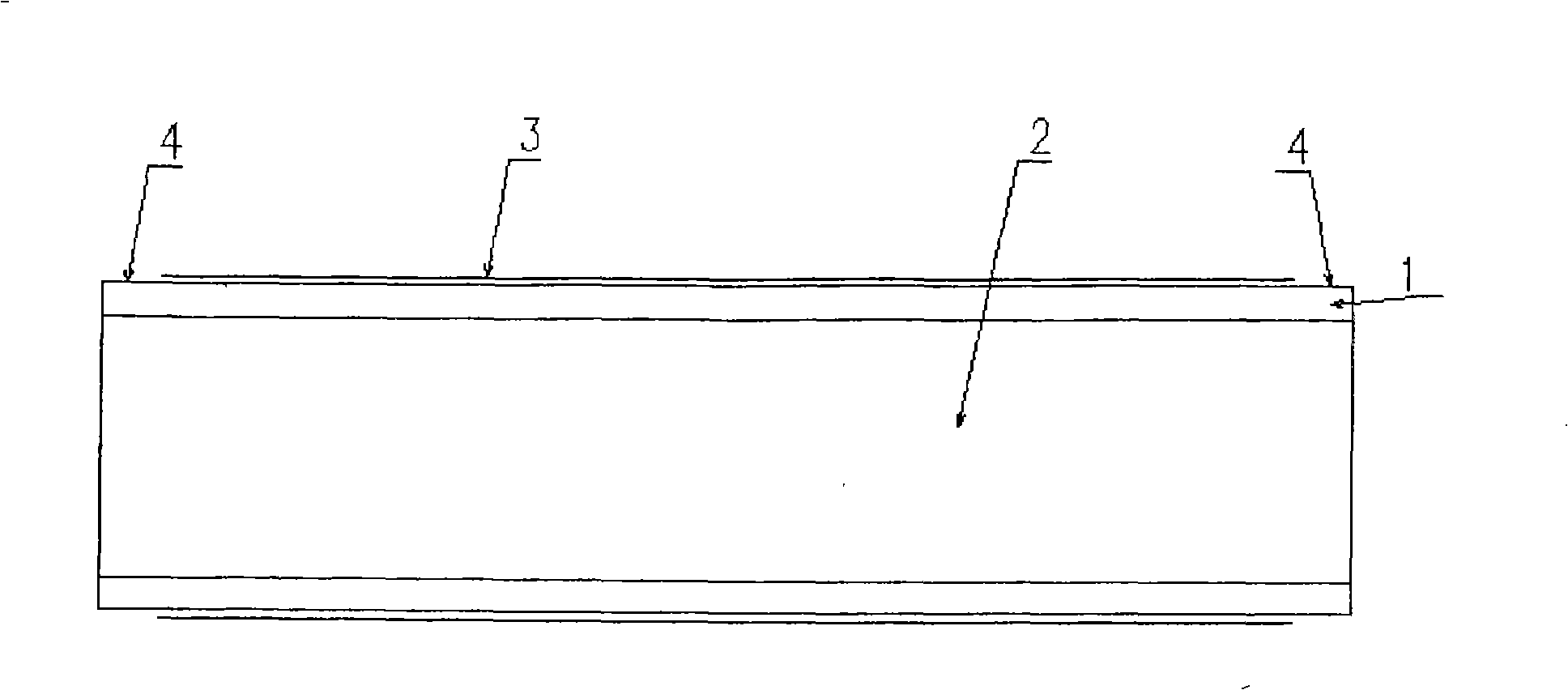

[0016] Depend on figure 1 , the base material of the heat collecting tube is a steel pipe 1, and a layer of solar energy selective absorption coating 3 is deposited on its outer surface. It is gas or liquid. When the sunlight irradiates the heat collecting element, its absorbing coating 3 absorbs sunlight to heat the base material steel pipe 1 to 200-500°C, and the heat is transferred to the working medium in the inner cavity 2 to generate high-pressure steam or high-temperature liquid According to actual needs, the base material steel pipe 1 can be made of stainless steel, carbon steel, nickel alloy, copper aluminum or aluminum alloy pipe or plate, the length of which is 300-600mm, and the inner diameter of the inner cavity 2 is greater than 10mm.

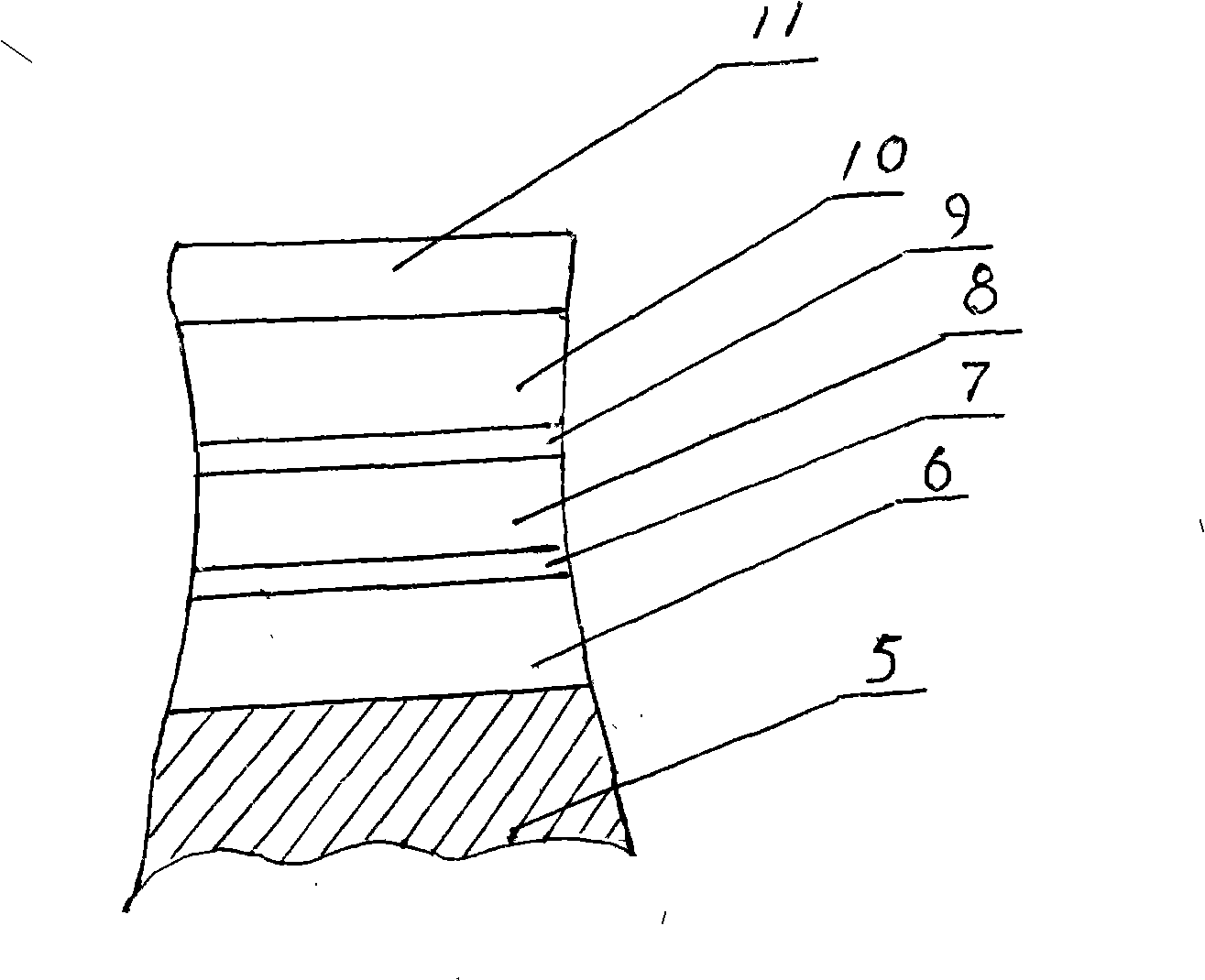

[0017] Depend on figure 2 , the solar selective absorbing coating 3 is a 6-layer structure, the base material 5 is a part of the base material steel pipe 1, and the surface of the base material 5 is baked at a high temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com