Frequency conversion power source based on digital signal processor controlling

A variable frequency power supply and digital signal technology, which is applied in the direction of control system, AC motor control, intermediate conversion to DC conversion equipment, etc., can solve the problem that the speed of asynchronous motor cannot be controlled by switching value, and the speed of asynchronous motor cannot be adjusted independently , special frequency converter for weft feeder is small in size, etc., to achieve excellent dynamic characteristics, shorten the design cycle, and reduce the difficulty of design and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

[0046] The present invention can be used for frequency conversion and speed regulation of various double-jet weft feeders, and other occasions where frequency conversion and speed regulation of two asynchronous motors are required simultaneously.

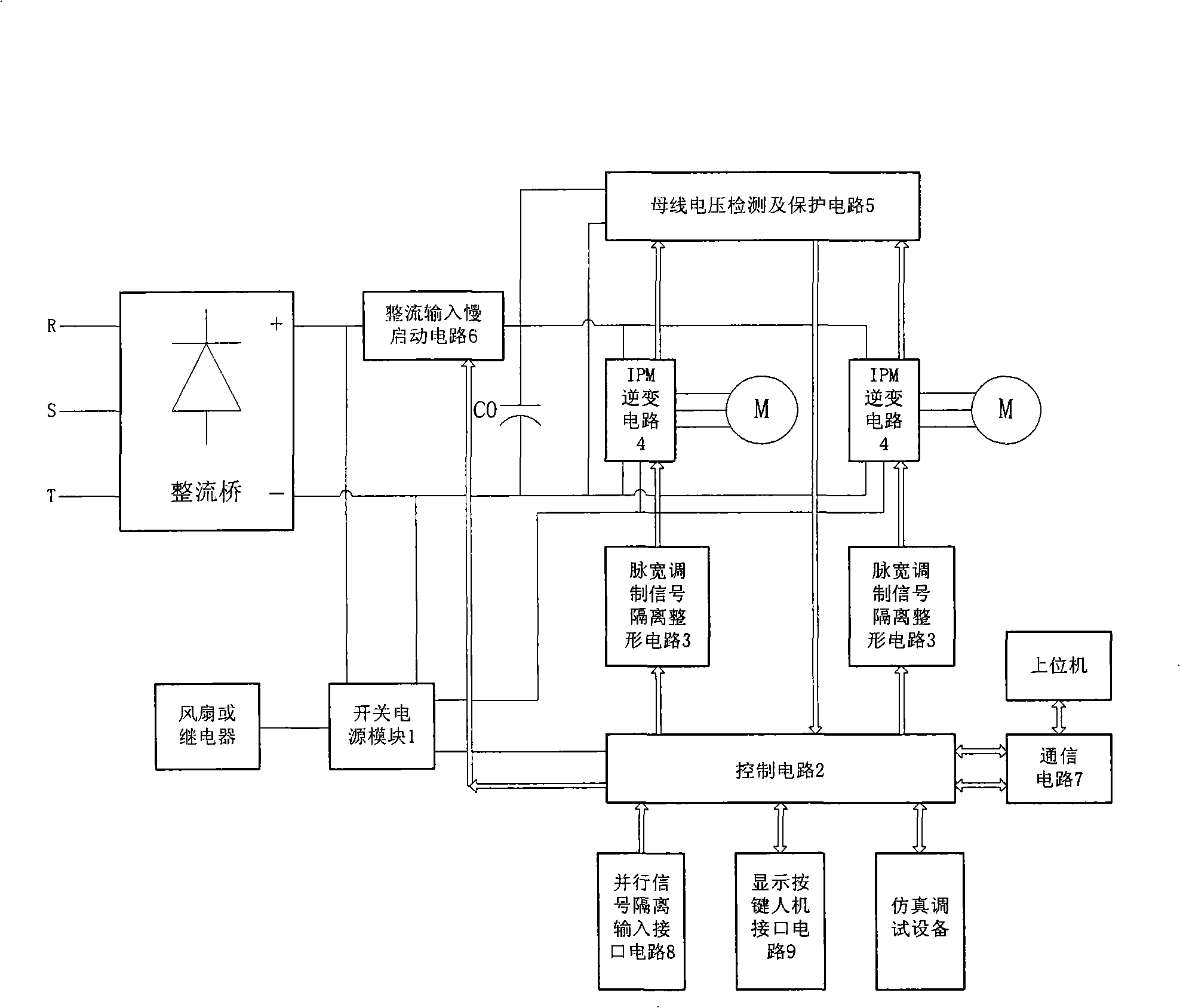

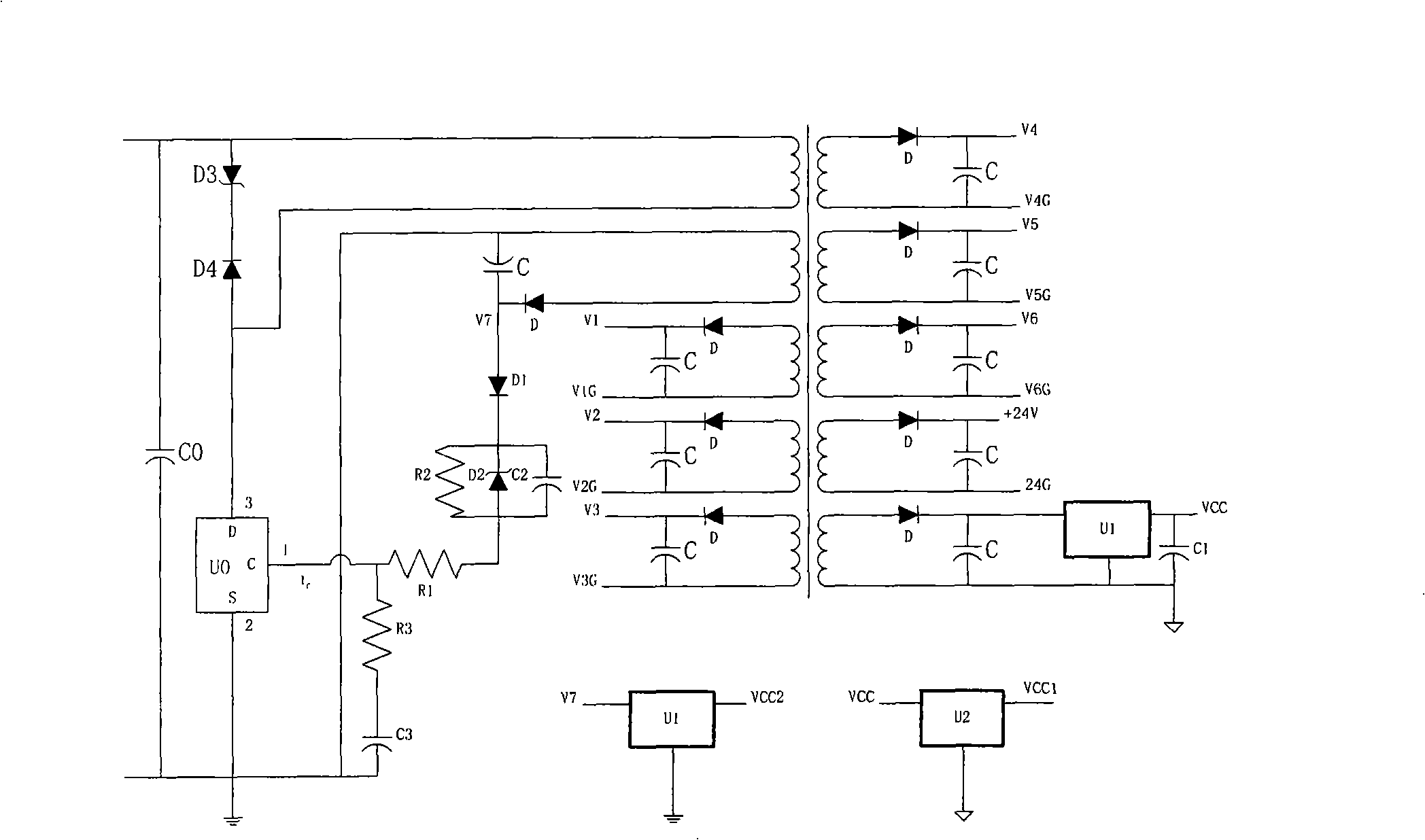

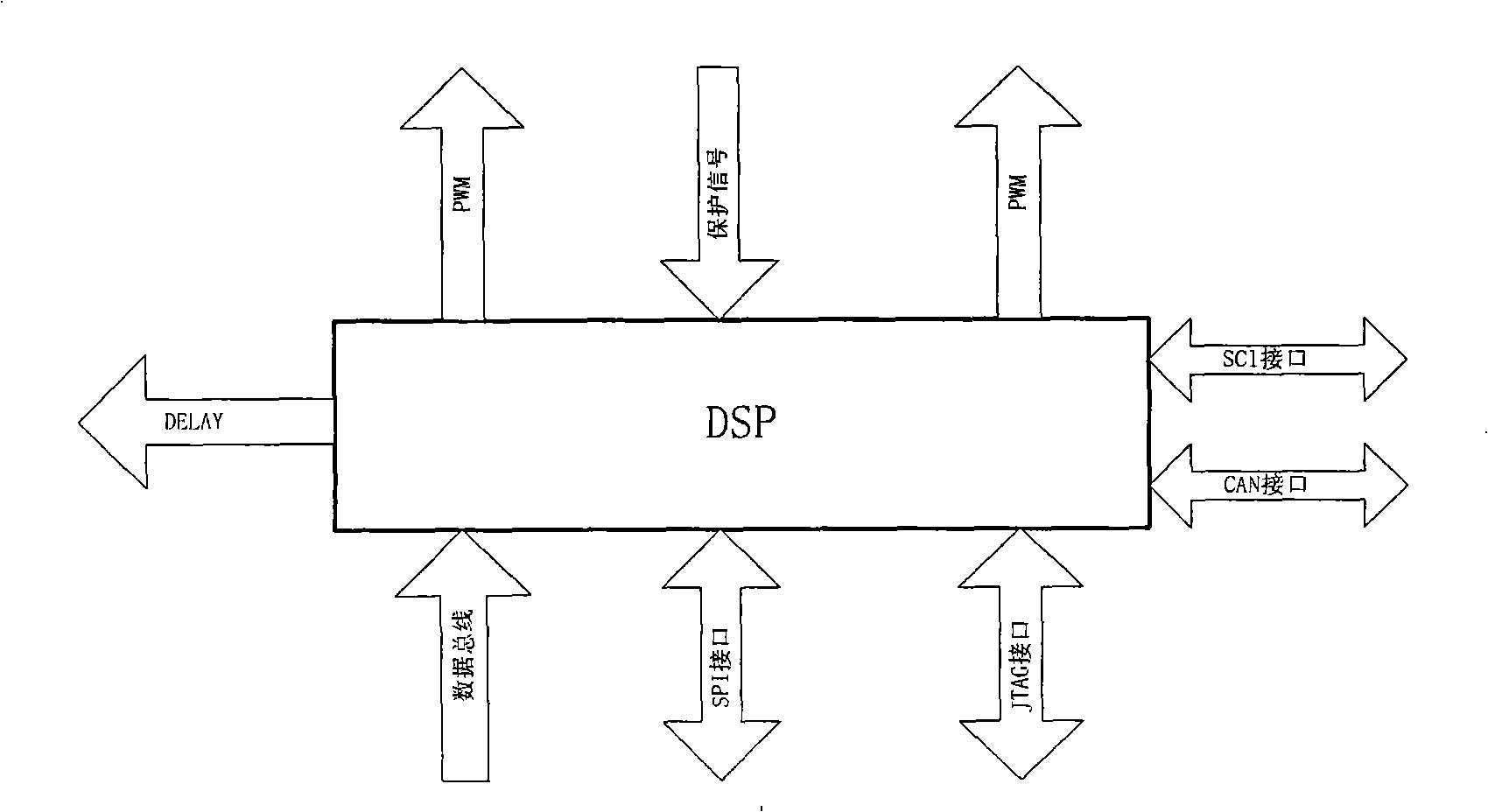

[0047] The present invention only enumerates the embodiment of the dedicated variable frequency power supply for double-jet weft feeders controlled based on digital signal processors, refer to figure 1 , is an overall block diagram of the circuit structure of the embodiment of the present invention. It consists of switching power supply module 1, control circuit 2, pulse width modulation signal isolation shaping circuit 3, IPM inverter circuit 4, bus voltage detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com