Controller for controlling a drive mechanism of a powered industrial truck

A ground conveying and power-driven technology, which is used in motor vehicles, trolleys, multi-axis trolleys, etc., can solve the problems of slow triggering of micro switches, jumping start of safety switches, and one-sided impact of magnets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

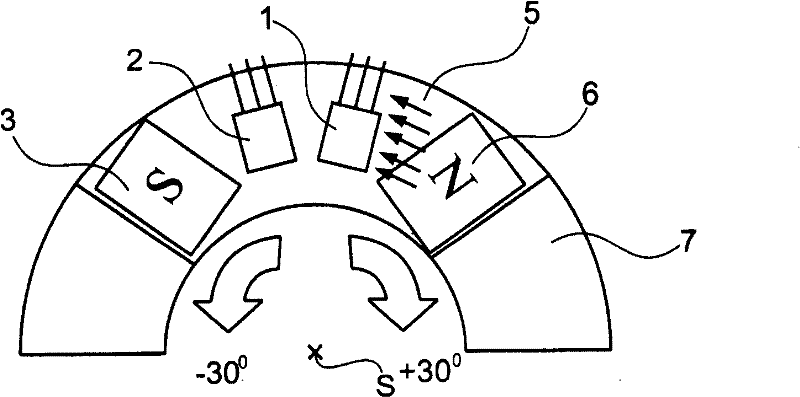

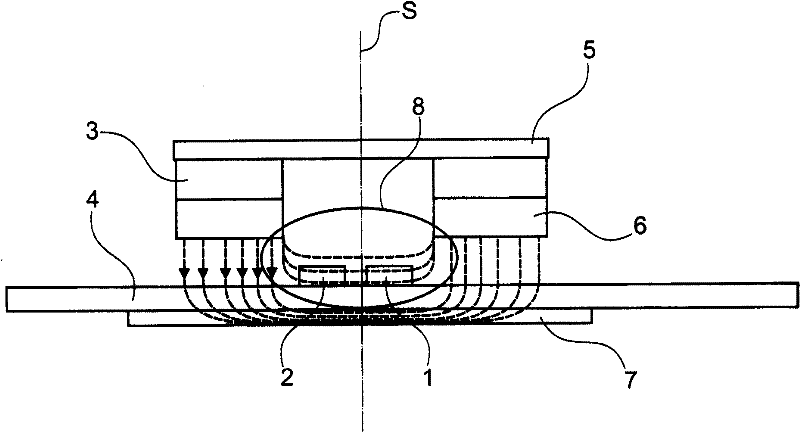

[0024] The illustrated embodiment of the drive controller according to the invention comprises a first Hall sensor 1 and a second Hall sensor 2, which are arranged on a circular arc and fixed flat on a printed circuit board 4 with a lateral angular distance on one side of the Above the printed circuit board 4 two permanent magnets 3 , 6 are arranged on a yoke 5 . The permanent magnets 3 and 6 are positioned such that their pole axes run parallel but in opposite directions. The yoke 5 serves on the one hand as a magnetic carrier and on the other hand serves to conduct the magnetic flux lines from one permanent magnet to the other in a bundled manner.

[0025] The yoke 5 is partially annular and can be figure 1 and 2 The intermediate positions shown in are offset about the axis S by about ±30°.

[0026]Also arranged on the side of the printed circuit board 4 opposite the Hall sensors 1 , 2 is a magnetic yoke 7 which likewise has a partially annular design and extends over an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com