Chryseobacterium gleum for producing keratinase and separation method thereof

A technology of Chryseobacterium aureus and keratinase, applied in the field of microorganisms, can solve the problems of high cost of keratin, destruction of nutritional components, uneven hydrolysis degree, etc., and achieve high keratinase activity, improved product performance, and simple post-processing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

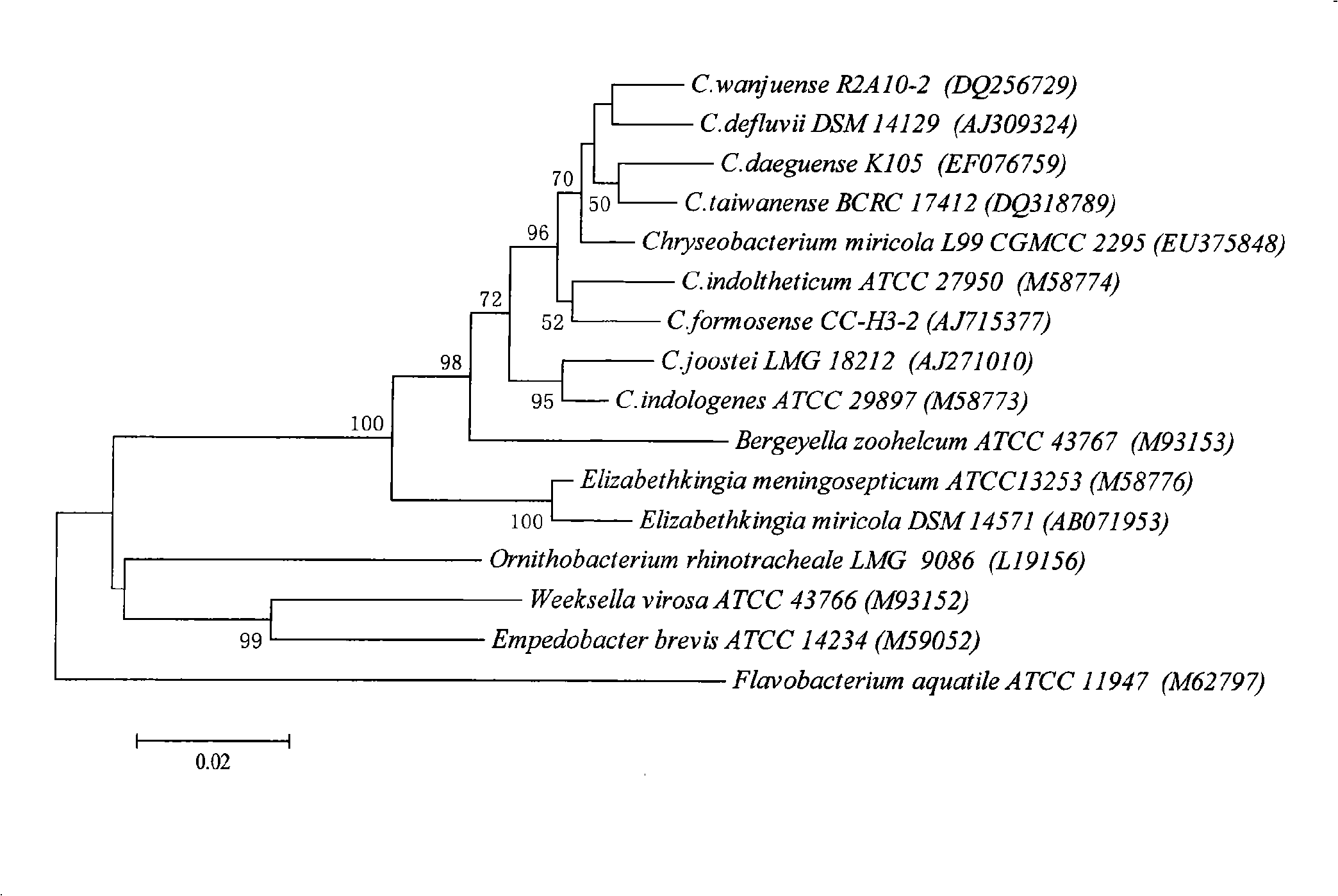

Image

Examples

Embodiment 1

[0066] 1) Take 5ml of sewage containing feather waste, add it to 50ml enrichment medium, 30°C, 200rpm, enrich and cultivate for 72 hours; the composition of enrichment medium is: 5 grams of NaCl, beef extract 5 grams, 5 grams of peptone and 980 ml of water.

[0067] 2) Take 5ml of the above-mentioned enriched culture, add it to 50ml of liquid screening medium, cultivate under the same conditions, repeat the above screening step 3 times, take 10 μl of culture solution to dilute and apply it on the solid screening medium. The composition of the solid screening medium is: every 1000 milliliters contains 20 grams of feather meal, K 2 PO 4 4 grams, NaH 2 PO 4 2H 2 O 2 g, MgCl 2 ·6H 2 O 0.2 grams, 20 grams of agar powder and 980 milliliters of water.

[0068] 3) Pick a single colony and culture it in a liquid screening medium, compare and select a strain with higher keratinase activity. The composition of the liquid screening medium is: every 1000 milliliters contains 20 gr...

Embodiment 2

[0070] 1) Take 10ml of sewage containing wool waste, add it to 100ml of enrichment medium, 30°C, 200rpm, and enrich and cultivate for 48 hours; the ingredients of the enrichment medium are: 10 grams of NaCl, beef extract 6 grams, 6 grams of peptone and 980 ml of water.

[0071] 2) Take 10ml of the above-mentioned enriched culture, add it to 100ml liquid screening medium, cultivate under the same conditions, repeat the above screening step 5 times, take 20 μl of the culture solution to dilute and apply it on the solid screening medium. The composition of the solid screening medium is: every 1000 milliliters contains 40 grams of feather meal, K 2 PO 4 5 grams, NaH 2 PO 4 2H 2 O 2 g, MgCl 2 ·6H 2 O 0.3 g, agar powder 15 g and water 980 ml.

[0072] 3) Pick a single colony and culture it in a liquid screening medium, compare and select a strain with higher keratinase activity. The composition of the liquid screening medium is: every 1000 milliliters contains 40 grams of f...

Embodiment 3

[0074] 1) Take 5ml of waste water containing hair, add it to 100ml of enrichment medium, 25°C, 200rpm, enrich and cultivate for 72 hours; the composition of the enrichment medium is: 10 grams of NaCl and 5 grams of beef extract per 1000 ml, 5 grams of peptone and 980 ml of water.

[0075] 2) Take 10ml of the above-mentioned enriched culture, add it to 100ml of liquid screening medium, cultivate under the same conditions, repeat the above screening steps 4 times, take 30 μl of culture solution to dilute and apply it on the solid screening medium. The composition of the solid screening medium is: every 1000 milliliters contains 30 grams of feather meal, K 2 PO 4 4 grams, NaH 2 PO 4 2H 2 O 2 g, MgCl 2 ·6H 2 O 0.5 grams, 20 grams of agar powder and 980 milliliters of water.

[0076] 3) Pick a single colony and culture it in a liquid screening medium, compare and select a strain with higher keratinase activity. The composition of the liquid screening medium is: every 1000 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com