Device for separating mud and water depending on high-frequency small-amplitude mechanical vibration

A technology of mud-water separation and mechanical vibration, which is applied in the direction of filtration separation, solid separation, sedimentation separation, etc., can solve the problems of different particle properties and cannot be applied to the use environment, etc., and achieve simple technical implementation, convenient operation and maintenance, and not easy to see plugs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

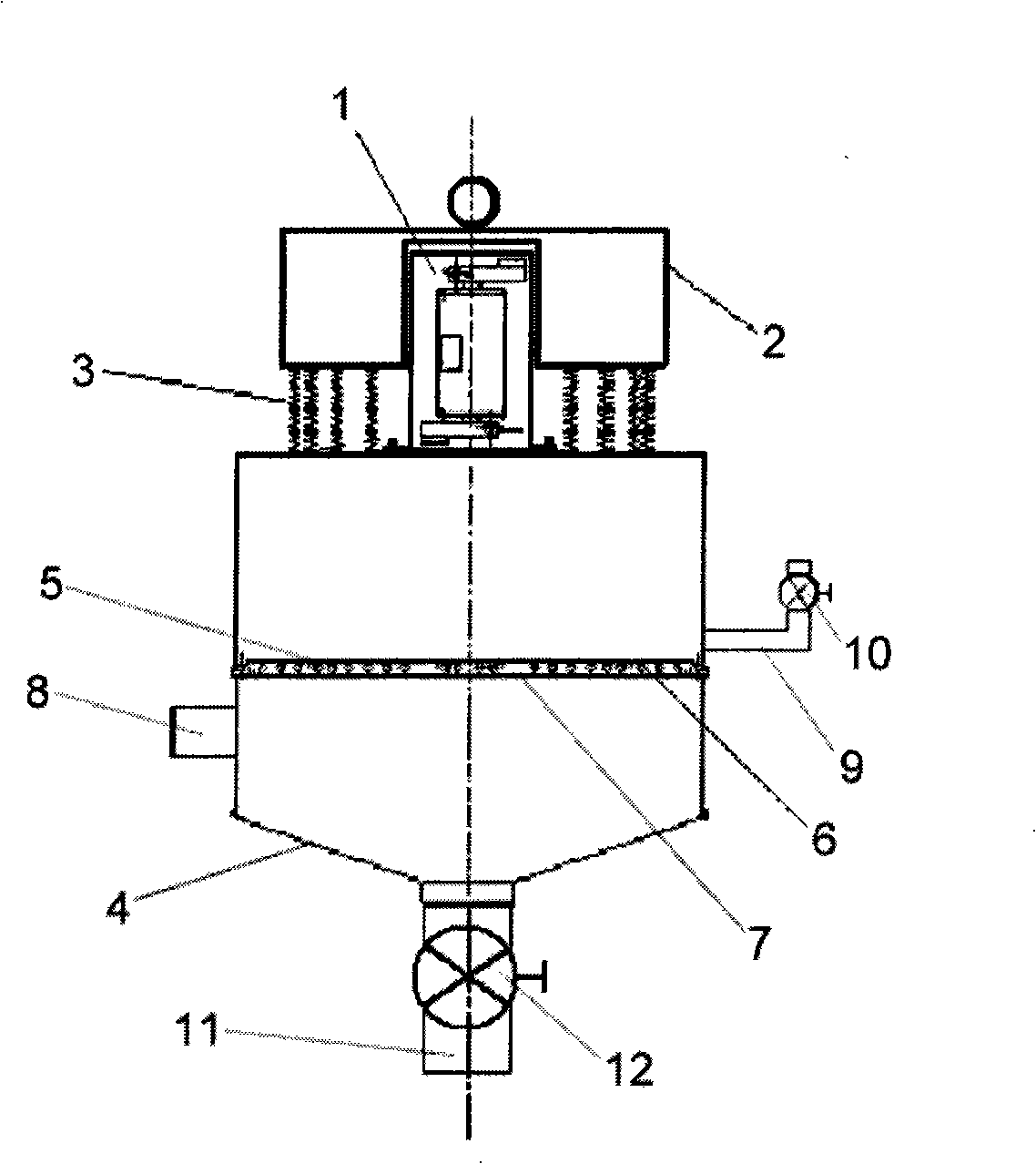

[0017] like figure 1 As shown, the present embodiment includes: a vibrating motor 1, a machine base 2, a spring 3, a mud-water separation chamber 4, a screen 5, a vibrating ball 6, a backing 7, an inlet pipe 8, an outlet pipe 9, an outlet pipe valve 10, an outlet pipe Mud pipe 11, mud pipe valve 12. The base 2 of the vibrating motor 1 is arranged on the mud-water separation chamber 4, the spring 3 connects the base 2 and the mud-water separation chamber 4, the screen 5 is arranged on the top of the vibrating ball 6, the bottom 7 is arranged on the middle part of the mud-water separation chamber 4, and the vibrating ball 6 is set between the screen 5 and the bottom 7, the water inlet pipe 8 is set on the mud-water separation chamber 4 and under the bottom 7; the outlet pipe 9 is set on the upper part of the mud-water separation chamber 4, and the outlet pipe valve 10 is set on the outlet pipe 9, the mud outlet pipe 11 is arranged at the bottom of the mud-water separation chamb...

Embodiment 2

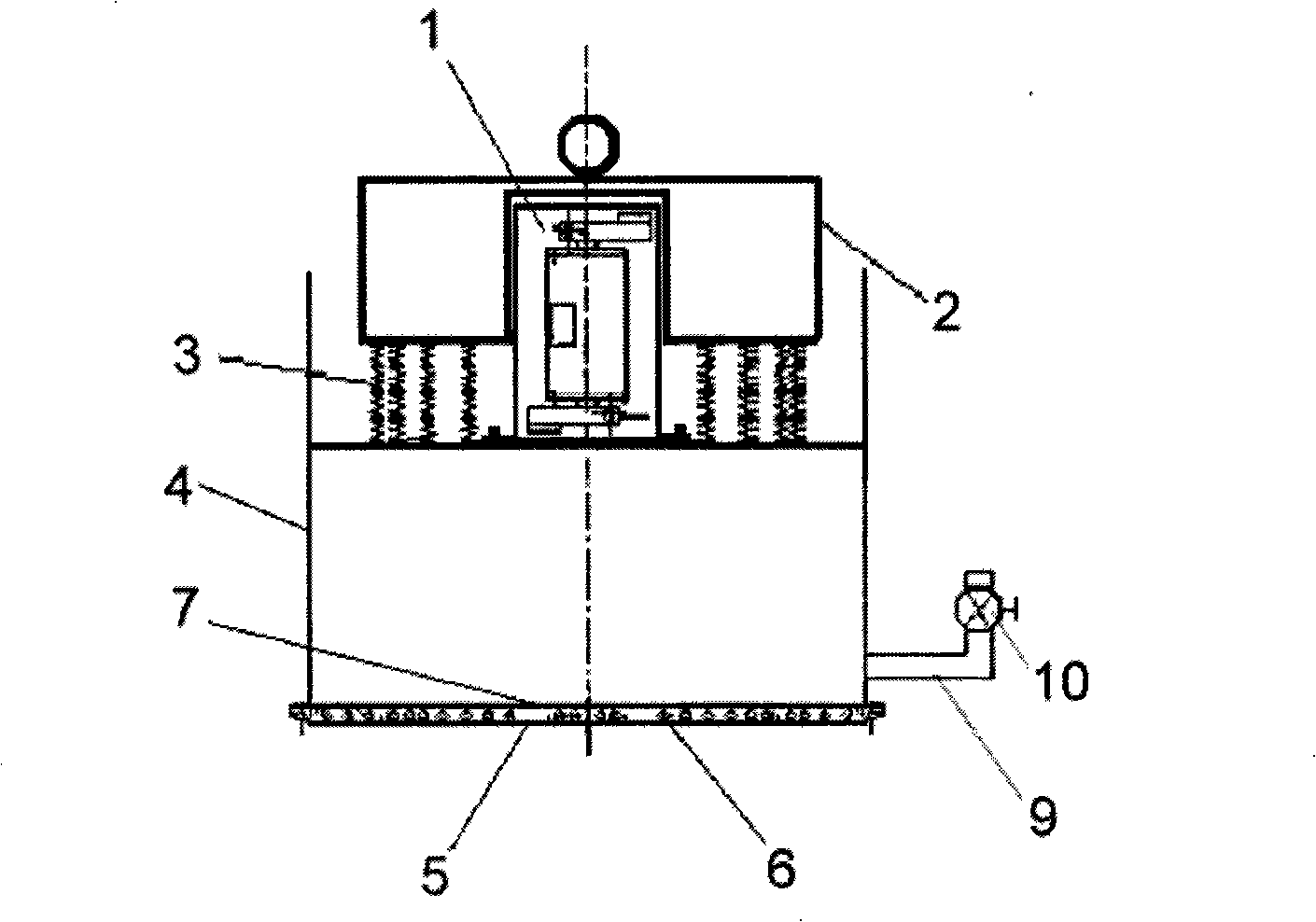

[0032] like figure 2 As shown, the present embodiment includes: a vibrating motor 1, a support 2, a spring 3, a mud-water separation chamber 4, a screen 5, a vibrating ball 6, a backing 7, an outlet pipe 9, and an outlet pipe valve 10. The base 2 of the vibrating motor 1 is arranged on the mud-water separation chamber 4 as a vibration source; the base 2 is installed on a support frame or a row frame. The spring 3 is arranged between the vibrating motor 1 and the mud-water separation chamber 4, and is connected by the spring 3, so that the part participating in the vibration becomes a complex three-dimensional movement in space; On the net 5, it is used to support the vibrating ball 6 and the screen 5, and is divided into several grids, and several vibrating balls 6 are placed in each grid; the vibrating ball 6 is arranged between the screen 5 and the bottom 7, and vibrates when working. The ball 6 continuously vibrates and hits the screen 5 to achieve the effect of clearing ...

Embodiment 3

[0035] This embodiment includes: vibrating motor 1, machine base 2, spring 3, mud-water separation chamber 4, screen 5, vibrating ball 6, bottom support 7, water inlet pipe 8, water outlet pipe 9, water outlet pipe valve 10, mud outlet pipe 11 , mud pipe valve 12. The vibrating motor 1 is arranged on the mud-water separation chamber 4, and the mud-water separation chamber 4 is cylindrical, with a height of 1.5 meters and a section diameter of 1 meter. The vibration frequency of the vibration motor 1 is 7200 times / minute, the maximum amplitude is 5mm, and the power is 1.5 kilowatts. The spring 3 made of stainless steel connects the support 2 and the mud-water separation chamber 4. The screen cloth 5 is arranged on the vibrating ball 6 top, and the bottom 7 is arranged at a height of 0.5 meters from the top of the mud-water separation chamber 4 . The screen 5 is woven by stainless steel wire, and the mesh size is 40 microns. The vibrating ball 6 is arranged between the screen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com