Bionic robot fish having up-down movement module and tail module

A technology of robotic fish and fish body, which is applied in the field of bionic robotic fish, can solve the problems of inconvenient adjustment of tail fin motion parameters, poor motion stability, and low diving speed, etc., and achieve fish body swings that are not obvious, easy to adjust, and motion stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

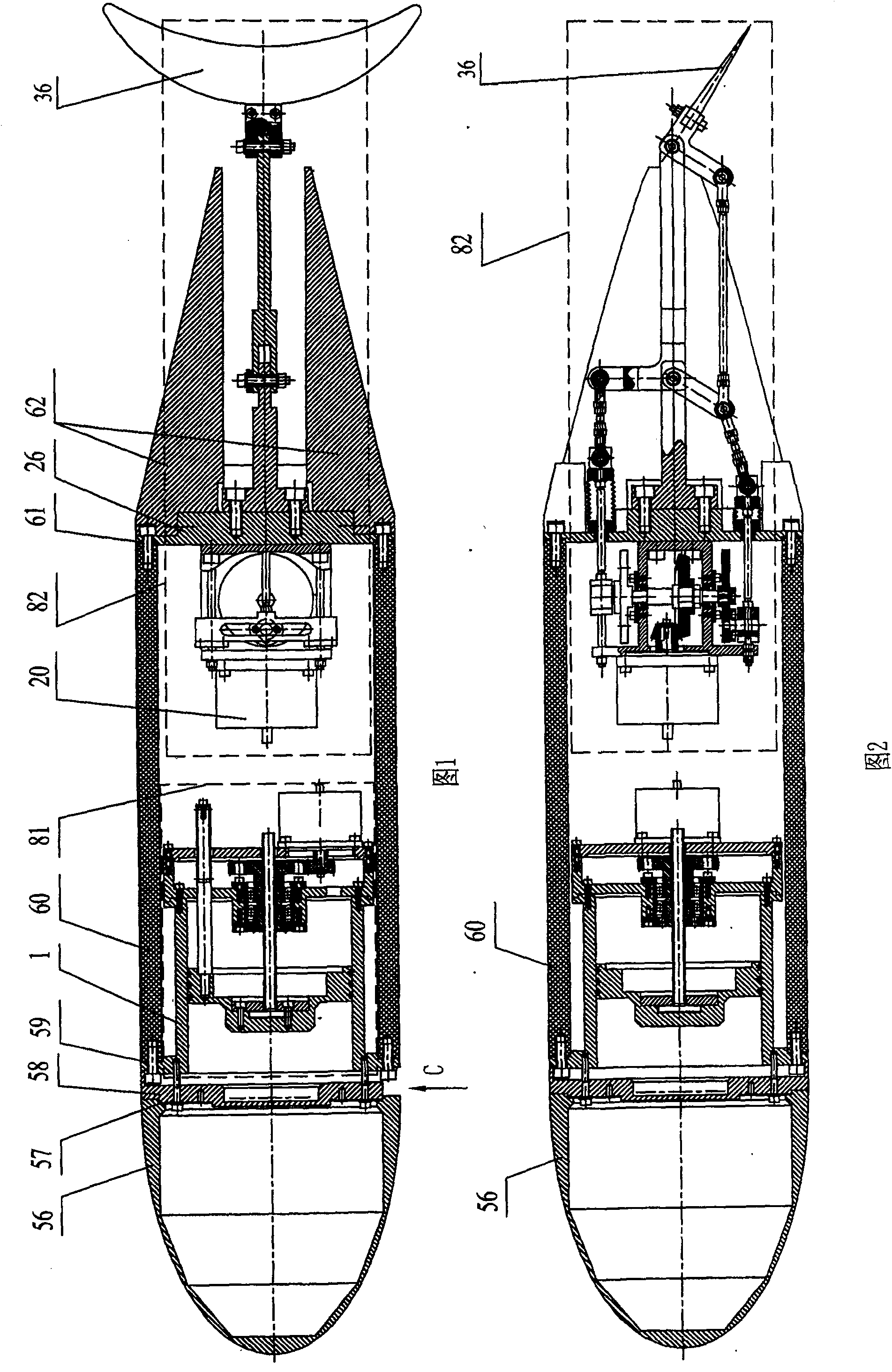

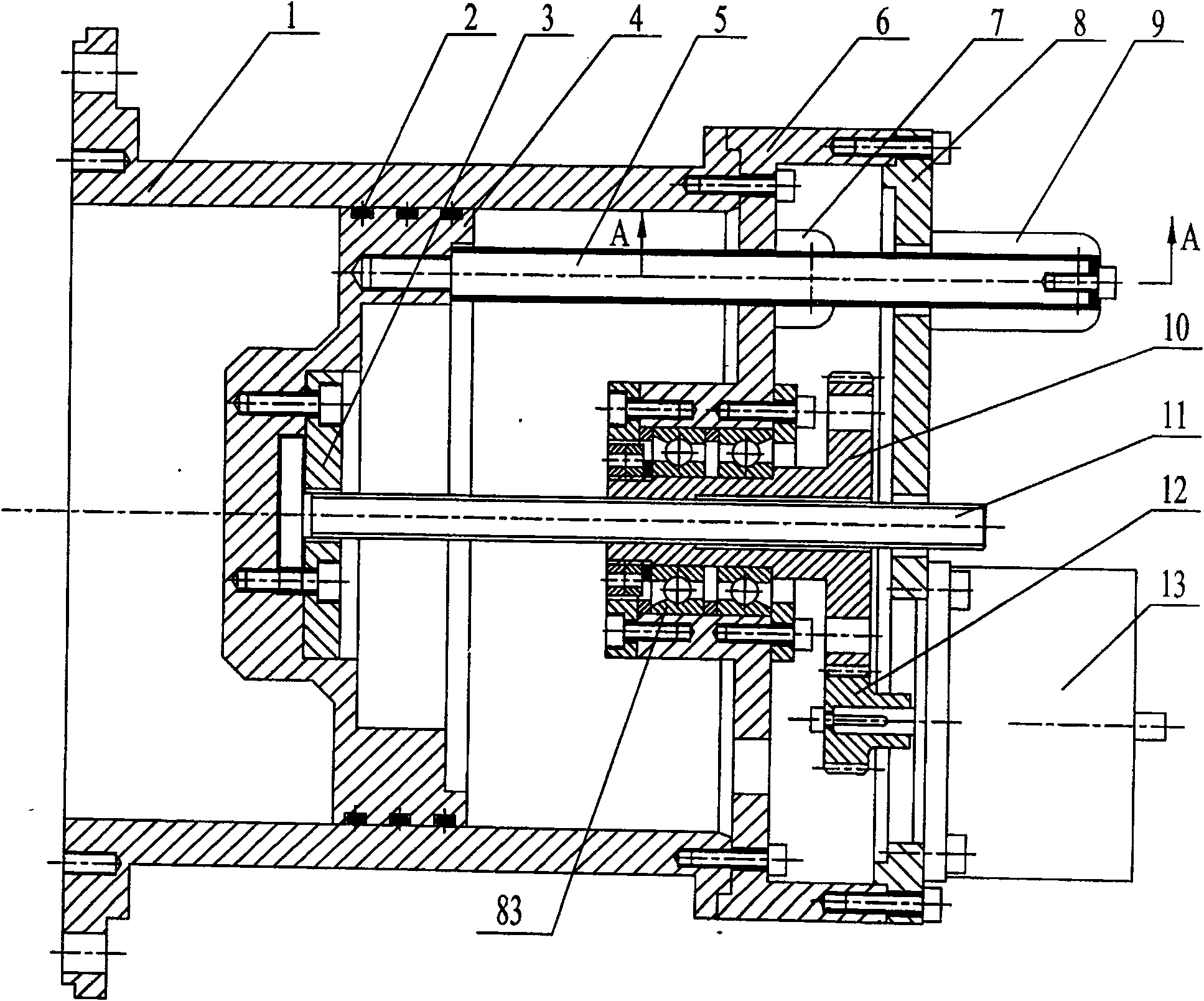

[0008] Specific implementation manner one: such as Figure 1~6 As shown, the bionic robotic fish having a submersible lift module and a tail module according to this embodiment includes a semi-elliptical fish head 56, a fish body tube 60, a conical tail body 62, and a support 58, The bionic robotic fish also includes a submersible lift module 81 and a tail module 82; the submersible lift module 81 includes a submersible lift module DC torque motor 13, a spur gear 12, a spur gear 10, a screw 11, and a cylinder tube 1. , Piston 4, screw end cover 3, cylinder end cover 6, motor support 8, bearing assembly 83; the tail module 82 includes a tail module lifting module DC torque motor 20, straight-tooth bevel pinion 37, straight Tooth bevel gear 38, box body 39, central shaft 43, first disc 22, second disc 44, first eccentric shaft 25, second eccentric shaft 41, two sets of sliding mechanism assembly 84, first connecting rod Assembly 85, second connecting rod assembly 86, end cap 26,...

specific Embodiment approach 2

[0009] Specific implementation manner two: such as Figure 1~6 As shown, the two sets of sliding mechanism assemblies 84 in this embodiment are respectively composed of a slider 24, two linear guides 21, two linear bearings 23, a tie rod 27, and a retractable rubber tube 28. The two linear guides 21 The two linear bearings 23 are respectively installed between the two linear guide rails 21 and the slider 24, and the two linear bearings 23 are respectively connected to the slider 24. The two ends of the two linear guide rails 21 are respectively fixedly connected to the box 39 and the end cover 26, the sliding block 24 is provided with a long hole 24-2 along the length direction, and the sliding part of the sliding mechanism assembly 84 The block 24 is installed at the eccentric position of the first disc 22 through the first eccentric shaft 25 installed in the long hole 24-2, and the slider 24 in the other sliding mechanism assembly 84 passes through the long hole 24. The seco...

specific Embodiment approach 3

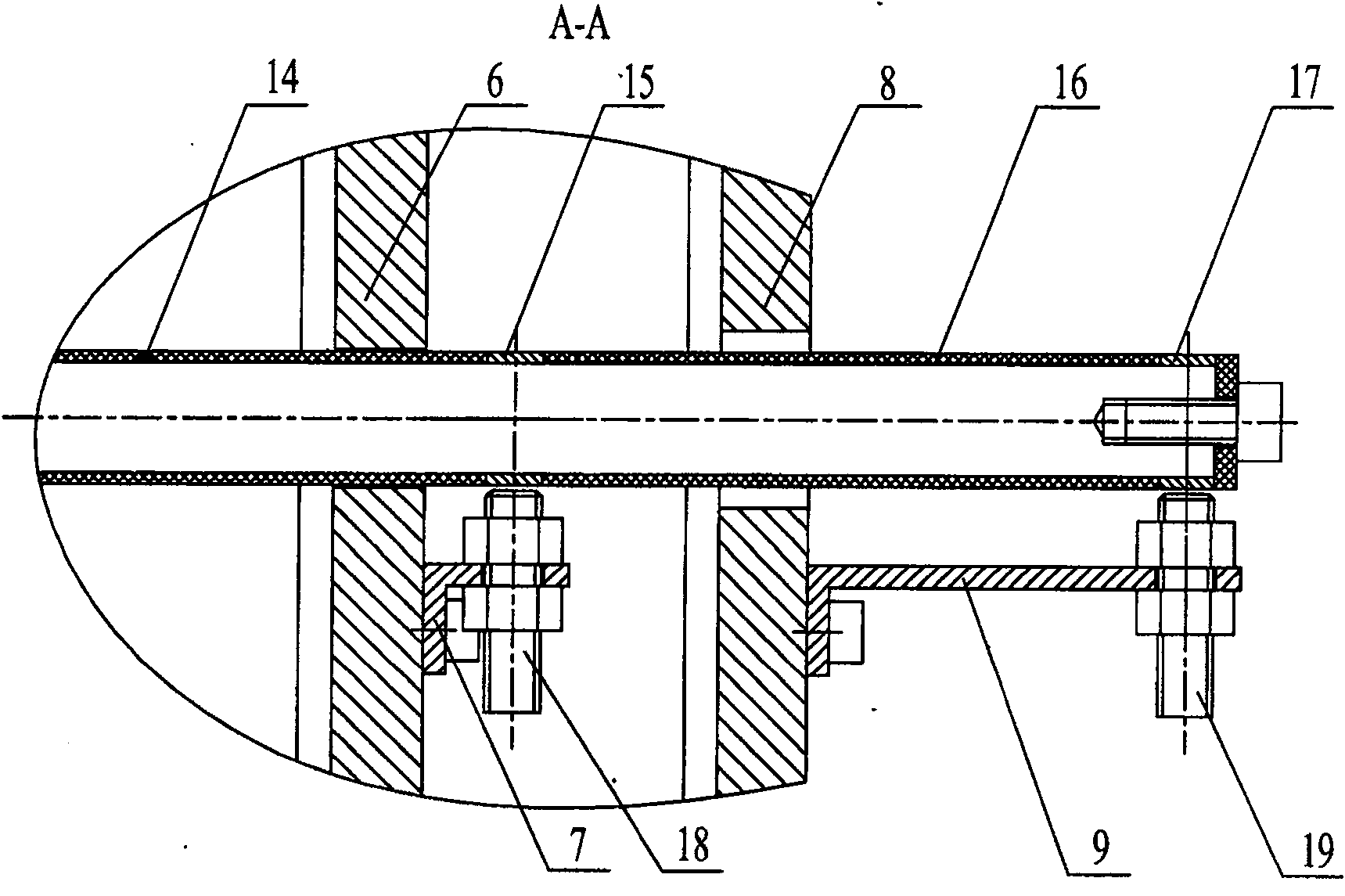

[0010] Specific implementation manner three: such as Figure 5 As shown, the first connecting rod assembly 85 and the second connecting rod assembly 86 described in this embodiment are all connecting rods with adjustable lengths. The first connecting rod assembly 85 and the second connecting rod assembly 86 are composed of a front joint 47, a middle connecting rod 48, and a rear joint 49. Both ends of the middle connecting rod 48 are respectively processed with left-hand threads and right-hand threads, The front joint 47 and the rear joint 49 are screwed together by the middle connecting rod 48. The length of the first connecting rod assembly 85 and the second connecting rod assembly 86 can be changed by rotating the middle connecting rod 48. The initial position of the tailstock can be corrected by adjusting the length of the first connecting rod assembly 85. By adjusting the second The length of the connecting rod assembly 86 can realize the adjustment of the water striking a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com