Method for inclined square prism stack to implement strip array semiconductor laser device beam shaping

A rhomboid prism and beam shaping technology, applied in prisms, optics, instruments, etc., can solve problems such as inconvenient design of adjustment mechanical parts, complicated fabrication of micro-chip prism stacks, and cost reduction, achieving shaping efficiency and system performance stability Improvement, compact structure, and system cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the shaping process of coupling the bar array semiconductor laser beam with the optical fiber with a core diameter of 800 μm and a numerical aperture of 0.37 is realized by the method of the present invention. The design process is as follows:

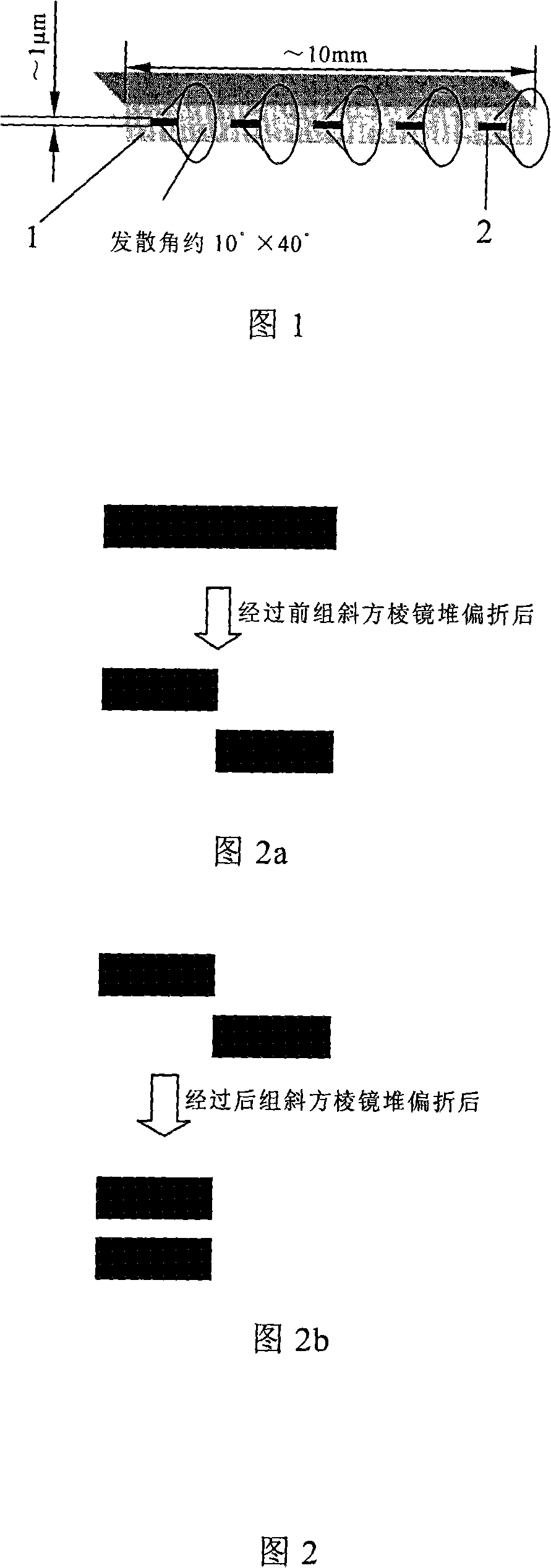

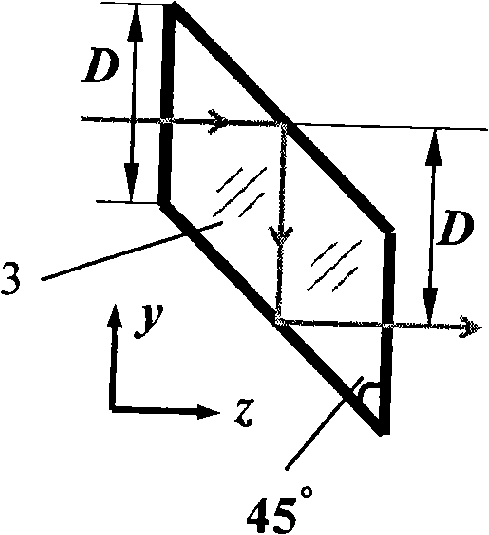

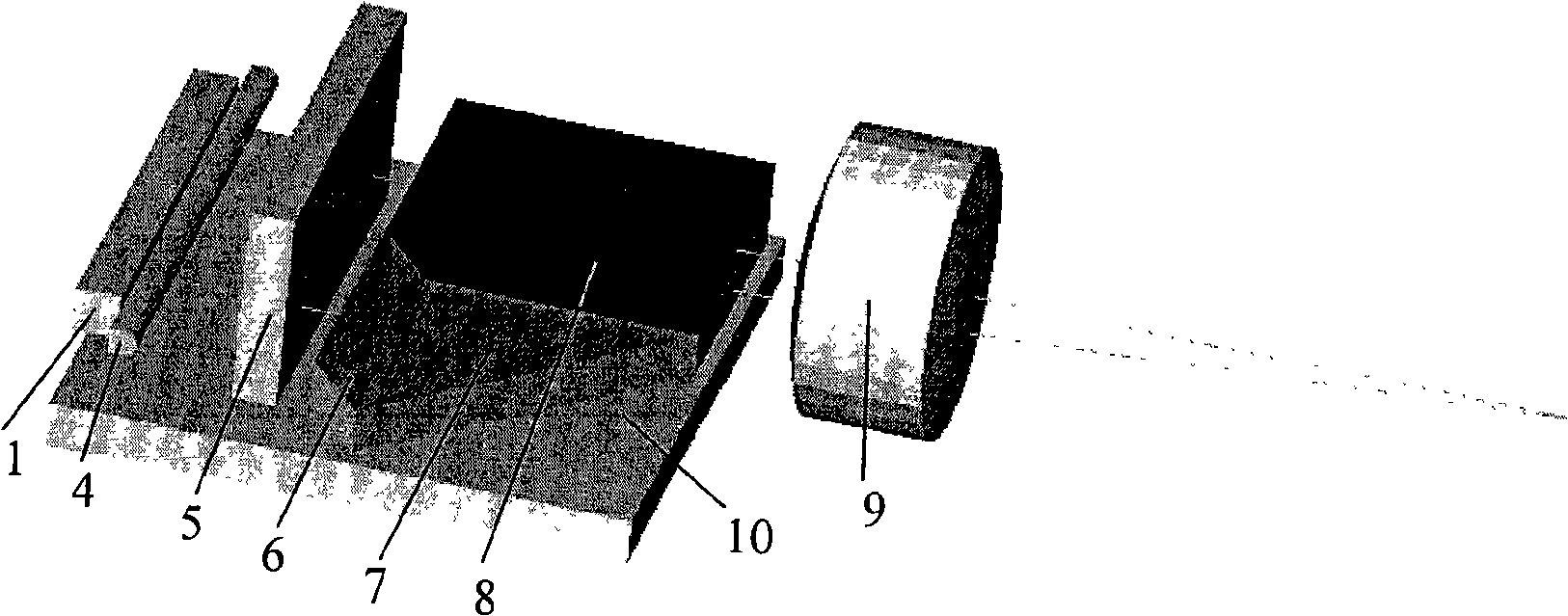

[0029] (1) After the fast and slow axes of the strip semiconductor laser 1 are collimated, the light spot size in the slow axis direction is about 10mm, and the number of deflection times of the slow axis light spot is N=2 times by using a rhombic prism, and aligned along the fast axis direction; the shaping system needs A parallel flat plate 8 and a front group rhombic prism 6 and a rear group rhombic prism 7, such as Figure 4 Shown; For the laser wavelength (such as 808nm) near the visible light, you can choose cheap K9 glass to make parallel plate 8, front group rhomboid prism 6 and rear group rhomboid prism 7. In this example, the width of the parallel plate 8 is selected as 6 mm. In order to ensure that...

Embodiment 2

[0036] (1) In the present embodiment, after the fast and slow axes of the strip semiconductor laser are collimated, the spot size in the slow axis direction is about 12mm, and the slow axis spot is deflected N=3 times by using a stack of orthorhombic prisms, and aligned along the fast axis direction; The system needs a parallel flat plate 15 and a reflective prism pile composed of two front group rhomboidal prisms and two rear group rhomboidal prisms; as shown in Figure 6, the two front group rhomboidal prisms respectively Prism 11 and the second rhombic prism 12 of front group, two rear group rhomboidal prisms are respectively the first rhombic prism 13 of rear group and the second rhombic prism 14 of rear group; Similar to embodiment 1, parallel plate 15, front The first rhombohedral prism 11 of the group and the second rhombohedral prism 12 of the front group, the first rhombohedral prism 13 of the rear group and the second rhombohedral prism 14 of the rear group are all mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com