Wedge type electrode holder

A technology of electric welding tongs and wedges, which is applied in the field of wedge-type electric welding tongs, which can solve the problems of reducing heat generation, hot handles, and contact resistance, and achieves the effects of reducing heat generation, solving hot handles, and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

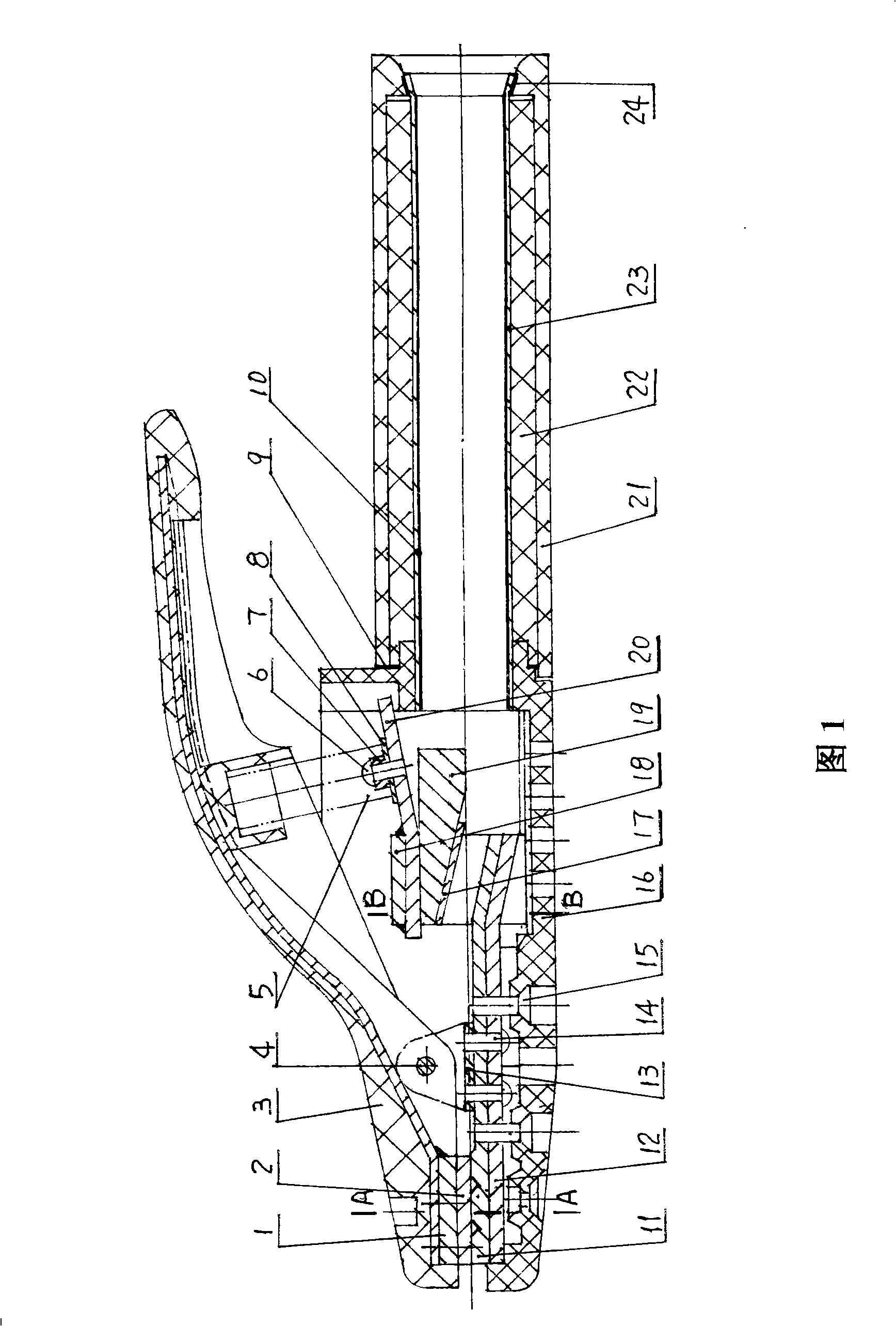

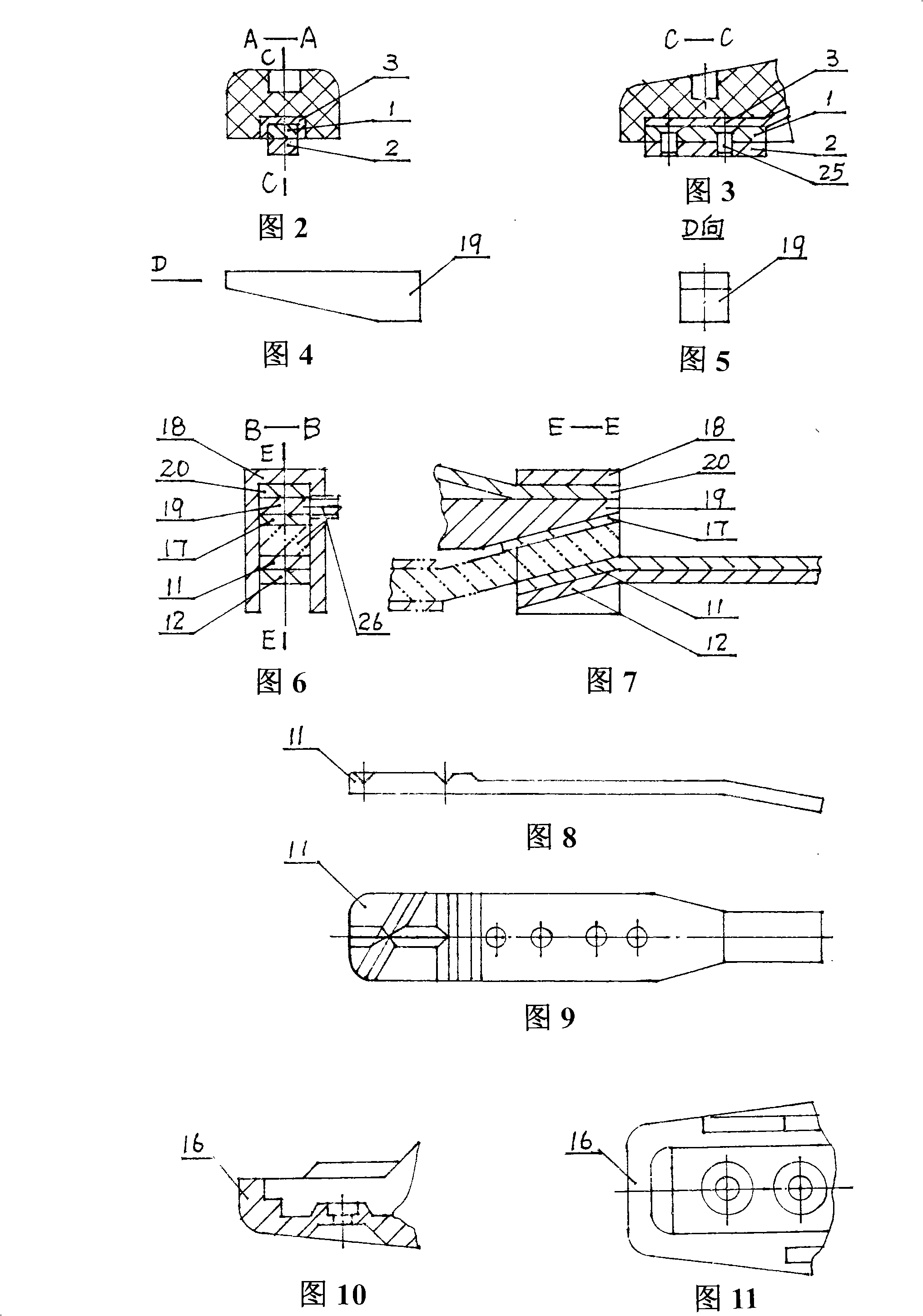

[0029] The specific structure of the present invention will be described in detail according to Fig. 1-11. The wedge-type electric welding tongs includes a joystick assembly, a wiring assembly, a handle assembly and other components assembled together. Wherein the joystick assembly includes: iron backing plate 1, upper clamp head plate 2, joystick 3, pin shaft 4, tension spring 5, screw 6, seat cover 7, insulating seat cushion 8 and other parts. Wiring assembly comprises: lower jaw plate 11, lower support iron plate 12, bearing 13, screw 14, screw 15, pressure wire plate 17, fixed frame 18, wedge-shaped briquetting block 19, spring support iron plate 20 etc. parts. The handle assembly includes: an insulator 16, a support tube 23, a heat insulator 22, a reflective film 10, a handle cover 21, a heat insulation pad 9, a heat insulation ring 24 and the like.

[0030] The iron backing plate 1 in the joystick assembly is welded together with the iron skeleton of the joystick 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com