Method for promoting thick oil oilfield oil well oil production

A technology for oil production and oil wells, applied in earthwork drilling and production, wellbore/well components, and production fluids, etc., can solve problems such as large safety risks, environmental pollution, and difficult platform power, and improve single well productivity and oil production Speed, great economic and technical benefits, effect of improved seepage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

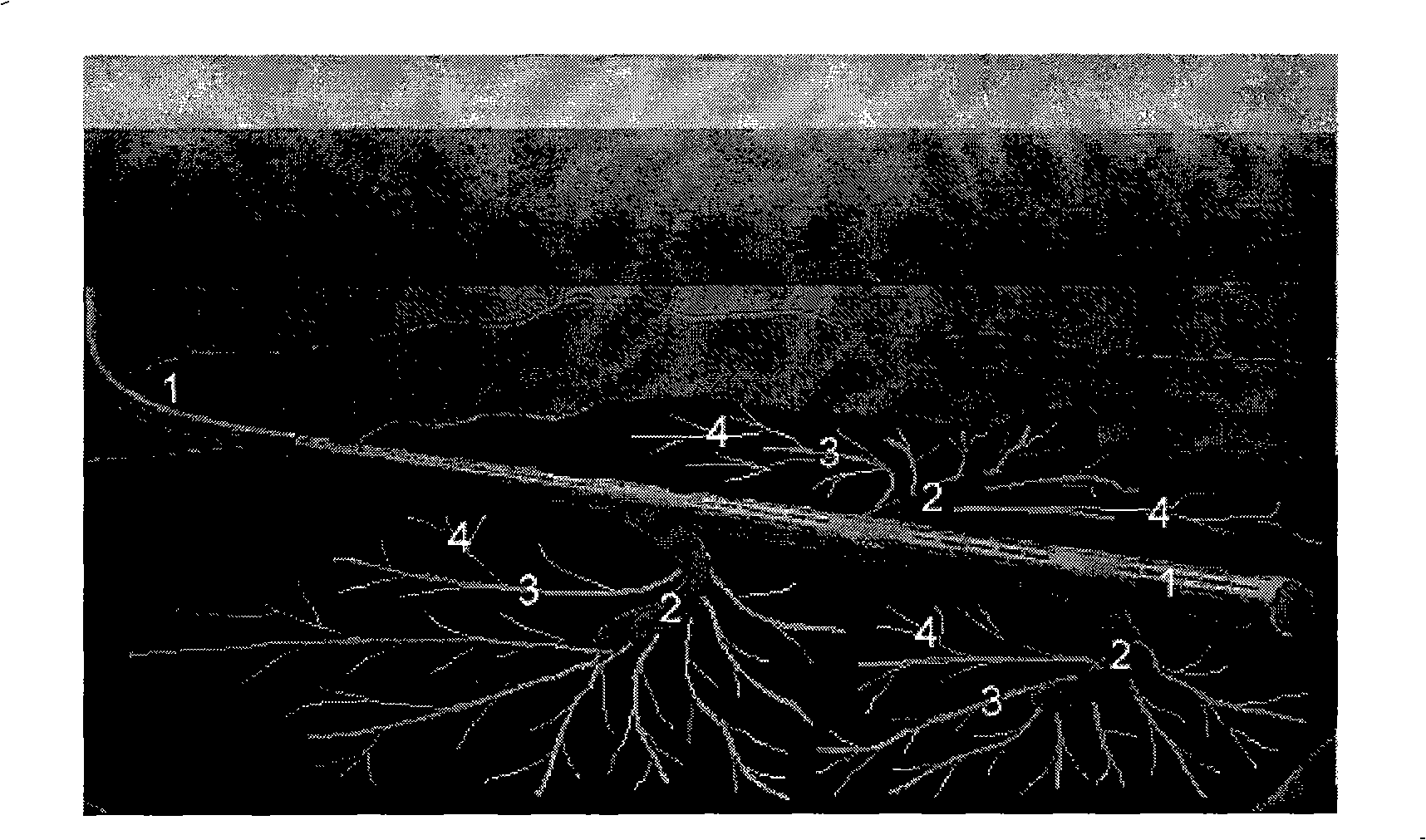

[0019] Example 1. The method of drilling to induce oil flow channels in Bohai A heavy oil field

[0020] In the oil layer, two horizontal branch boreholes are drilled in the oil layer by drilling method, which are respectively arranged on both sides of the main borehole and communicated with the main borehole. Several induced oil flow channels are formed around the branch borehole. The oil well has a production of 47 m3 / day, the water content of crude oil is 9.6%, and the production is stable for more than 680 days.

[0021] As a comparison, the adjacent common oil well is 34 cubic meters per day, the crude oil contains 5.6% water, and the crude oil production shows a natural decreasing trend. The method of the invention can increase the oil production by 0.4 times.

example 2

[0022] Example 2: The method of drilling to induce oil flow channel in Bohai B heavy oil field

[0023] In the oil layer, three horizontal branch wellbores are drilled in the oil layer by drilling method, which are connected with the main wellbore, and a number of induced oil flow channels are formed around the branch wellbore. As a result, several secondary oil flow channels are formed in the induced oil flow channel, thereby forming a three-dimensional network of oil flow channels in the oil layer, which greatly increases the channel for heavy oil to flow to the wellbore in the formation. The output of this oil well is 109 cubic meters per day, the water content of crude oil is 43.8%, the water content is stable, and the production has been stable for more than 77 days.

[0024] As a comparison, the adjacent common oil well is 11 cubic meters per day, the crude oil has a water content of 85.5%, and the water content of the crude oil shows a gradual upward trend. The method ...

example 3

[0025] Example 3: The method of drilling to induce oil flow channels in Bohai C heavy oil field

[0026] The method of drilling in the oil layer is used to drill 6 horizontal branch boreholes in the oil layer, which are connected with the main borehole, and the distance between the horizontal branch boreholes is 50-100 meters. There are several induced oil flow channels around the branch wellbore, the fine powder flowing sand in the oil layer flows out with the oil, the skeleton structure sand remains unchanged, and several secondary oil flow channels are generated in the induced oil flow channel, thus forming in the oil layer The three-dimensional network oil flow channel greatly increases the channel for heavy oil to flow to the wellbore in the formation. The output of this oil well is 140 cubic meters per day, the water content of crude oil is 6.7%, the water content is stable, and the production has been stable for more than 22 days.

[0027] As a comparison, the adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com