Two stage hot pipe EGR cooler

A technology of EGR cooler and heat pipe, which is applied in machines/engines, adding non-fuel substances to fuel, internal combustion piston engines, etc., can solve the problem of reducing the cooling efficiency of EGR cooler, cavitation of engine cooling circuit, reducing the degree of vaporization of coolant, etc. problems, to achieve the effect of strong horizontal free scalability, reduce impact, and improve cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

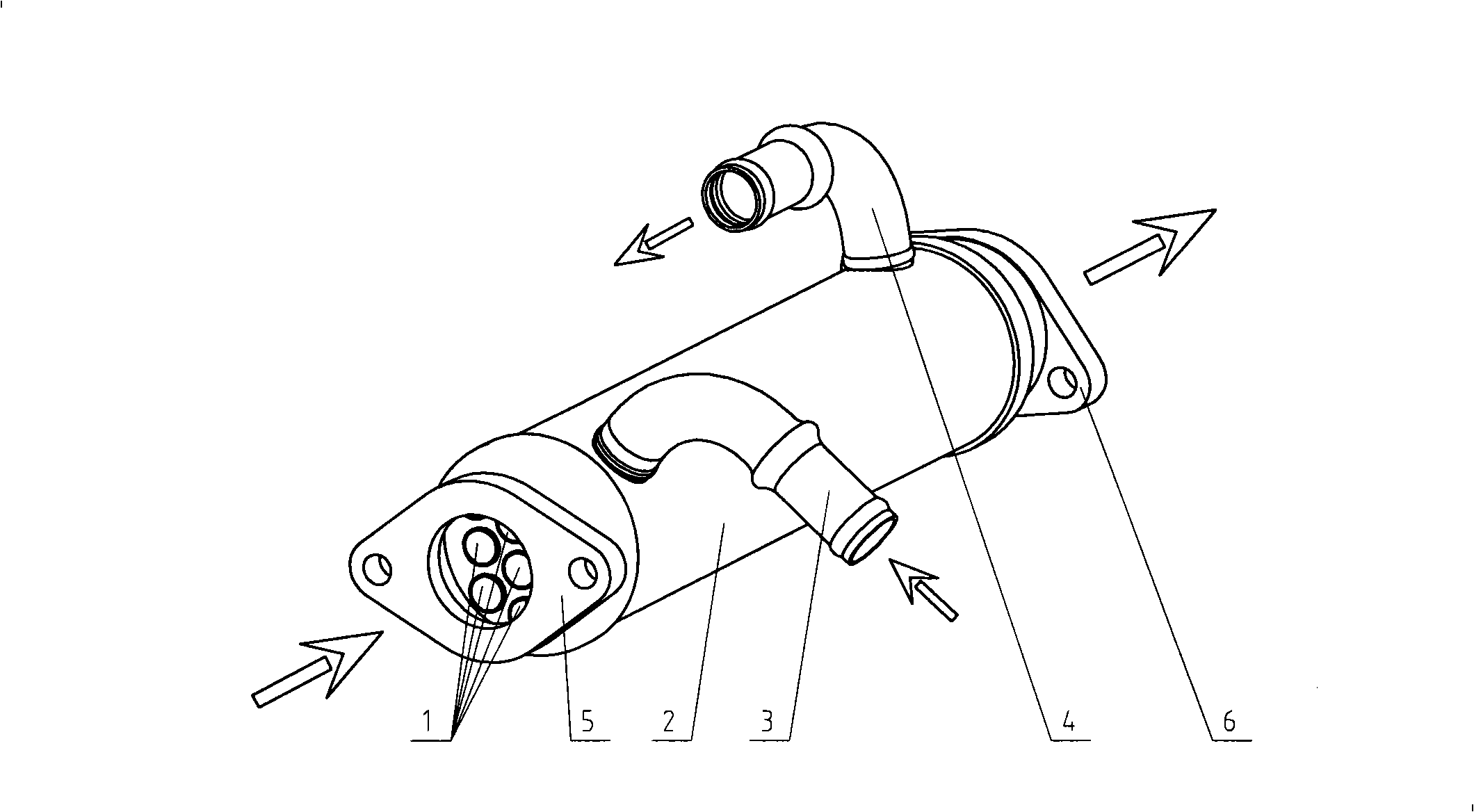

[0019] refer to figure 1 , this figure shows a traditional shell-and-tube EGR cooler, which includes a casing 2 with a coolant inlet 3 and an outlet 4 on the side, and a set of replacement parts arranged in parallel in the casing 2 with gaps between them. heat pipe1. The heat exchange tube 1 is connected to the exhaust gas recirculation circuit of the engine through an inlet flange 5 and an outlet flange 6 . And the engine coolant enters the inner cavity of the housing 2 from the coolant inlet 3 after being drawn out from the pipeline, then flows out from the coolant outlet 4, and is sent back to the engine cooling system by the pipeline. In this structure, in order to achieve a better heat exchange effect, the heat exchange tubes 1 are generally many and very thin. In the narrow pipes in the heat exchange tubes, the inner wall of the tubes is easy to be carbonized, and the carbonization is difficult to remove automatically, greatly Reduced cooling efficiency of the EGR cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com