Automobile chassis integrated controller hardware in-the-loop simulation test stand

A technology of integrating controller and automobile chassis, applied in the field of simulation test bench, can solve the problem of no chassis integrated controller and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0144] Please refer to the accompanying drawings for a further description of the present invention.

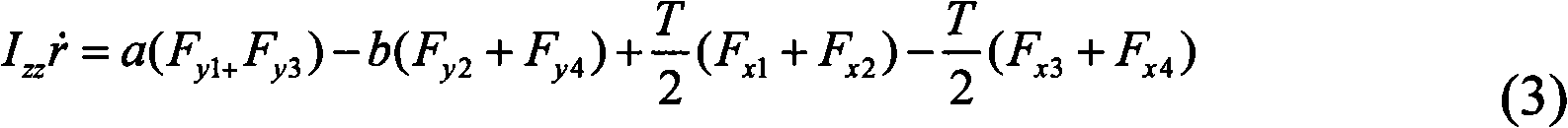

[0145] As shown in Fig. 6, the present invention provides a hardware-in-the-loop simulation test bench for an integrated controller of an automobile chassis, including a host machine 1, a target machine 2, and an electronic control unit 3. Degree of freedom dynamics model, tire road surface model, hydraulic and braking system model, engine and transmission system model, and establish digital simulation models of various driving conditions for evaluating and optimizing control strategies, convert them into C code format, and send them via Ethernet The network is received and downloaded by the target machine 2 into its CPU, and the electronic control unit 3 controls the normally open valve, normally closed valve and DC motor of the solenoid valve 5, receives the current status signal of the solenoid valve 5 through the PCL board 4, and passes the PCL board The card 4 feeds back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com