Thermoacoustic driving magnetohydrodynamic electricity generation system using ion liquid of room temperature

A room-temperature ionic liquid and magnetic fluid power generation technology, which is applied to electrical components, electromechanical devices, machines/engines, etc., can solve problems such as operating life that needs further verification, affecting system stability, and poor adaptability, so as to ensure long-term stability operation, improve energy efficiency, and increase the effect of sound power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

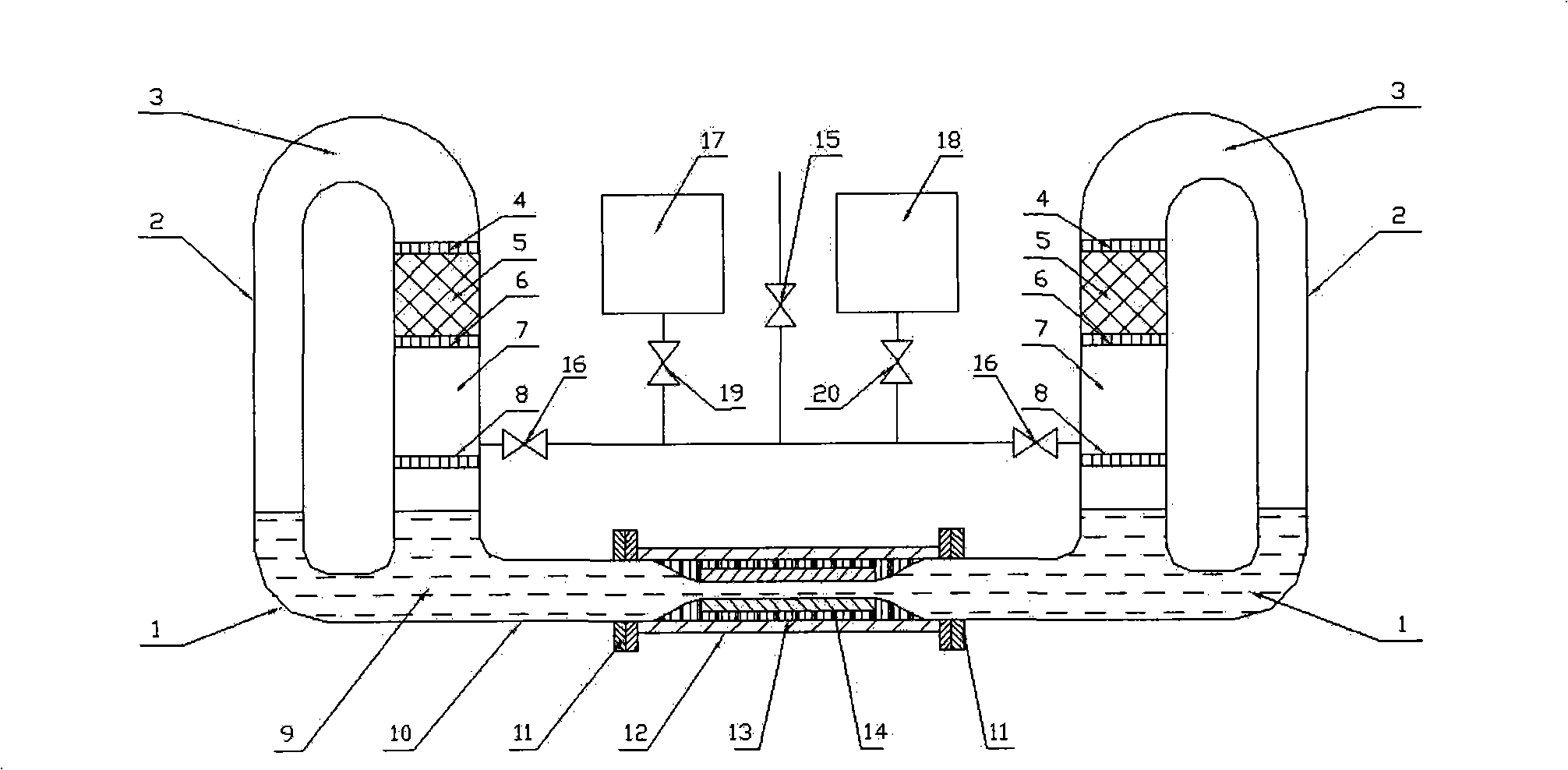

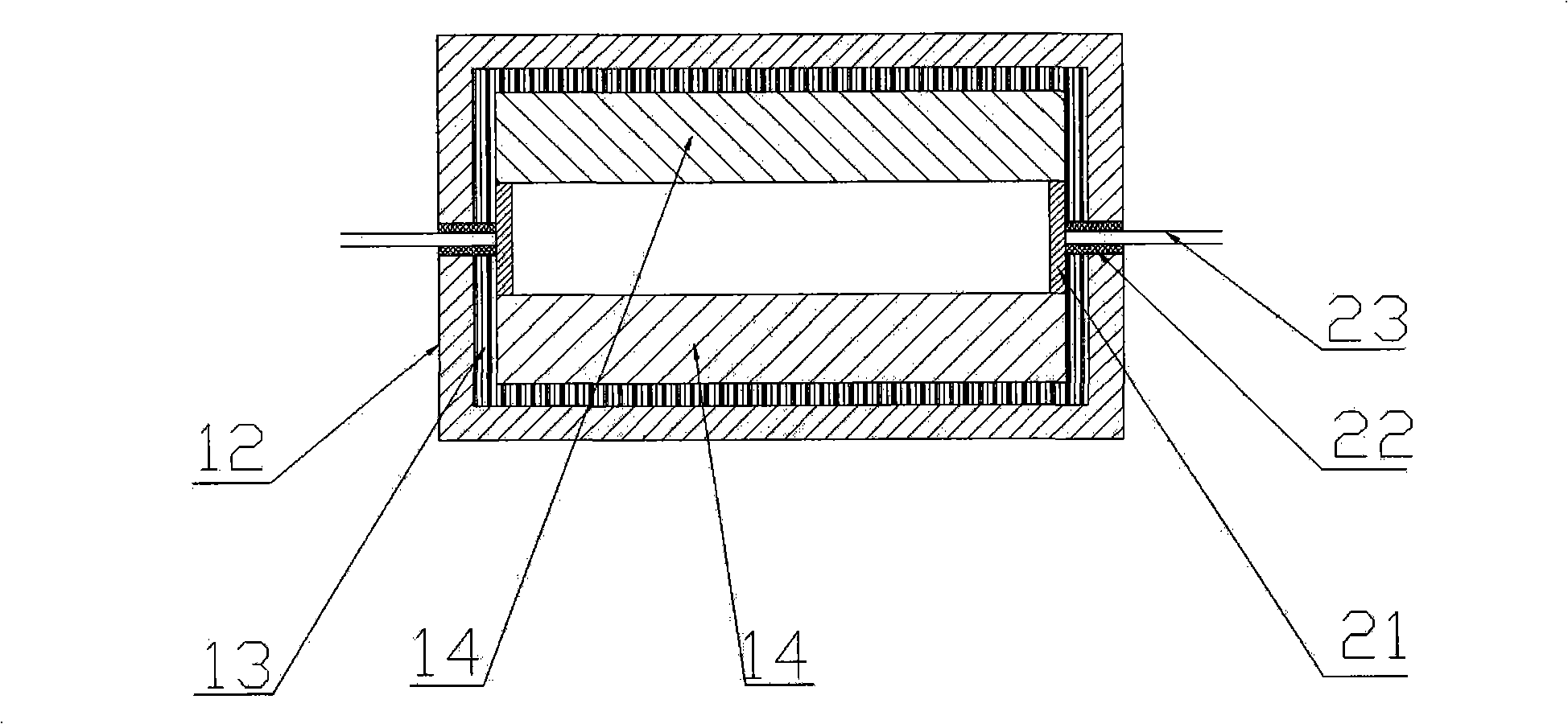

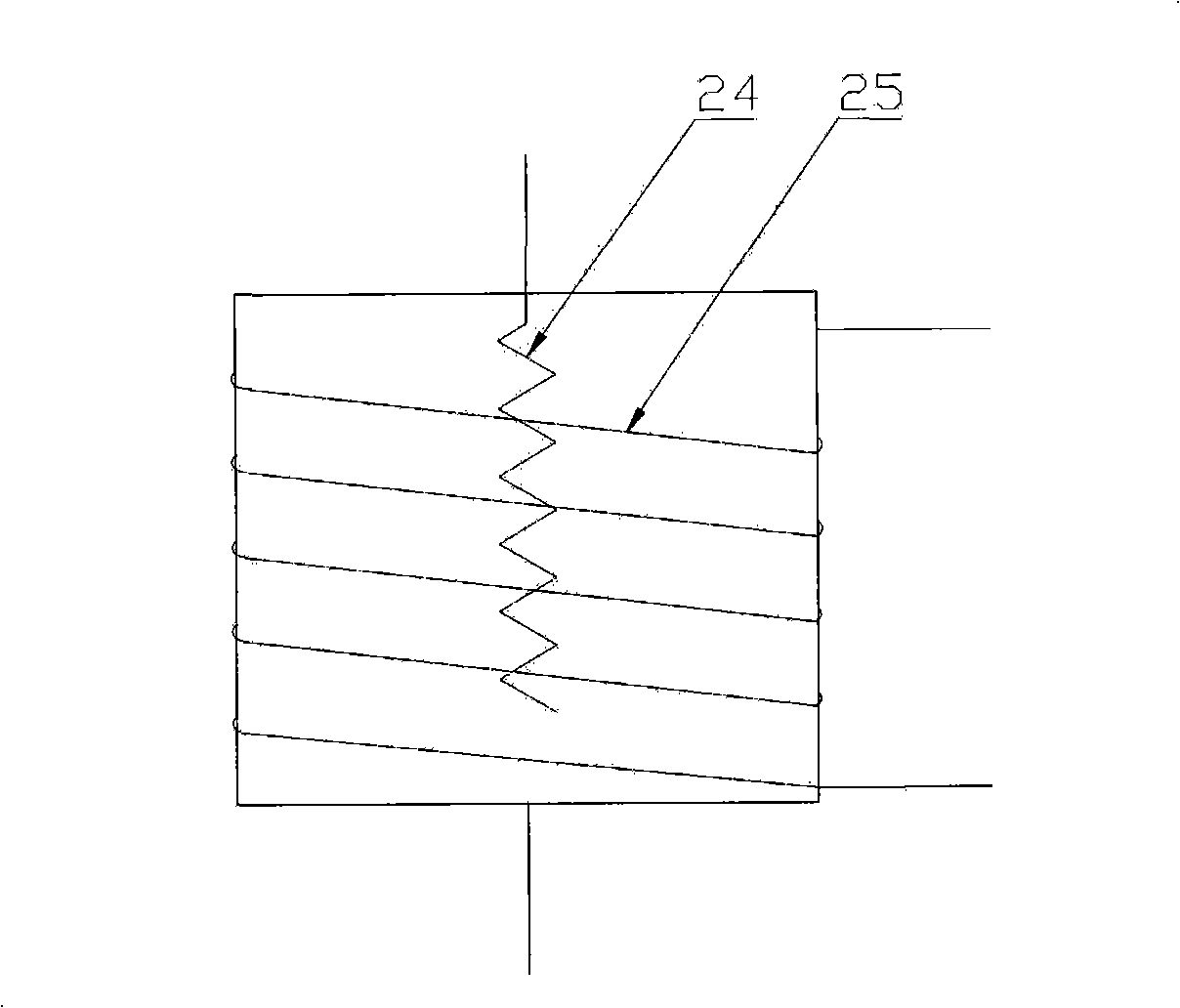

[0017] As shown in the figure, the thermoacoustic-driven magnetic fluid power generation system using room temperature ionic liquid includes a first loop traveling wave thermoacoustic core, a resonance tube 10, a room temperature ionic liquid 9, a power generation device, and a second loop traveling wave thermoacoustic core , a frequency stabilization device, the loop traveling wave thermoacoustic core includes a feedback tube 1, an acoustic sensor tube 2, a sound capacity tube 3, a first water cooler 4, a regenerator 5, a heater 6, and a thermal buffer tube 7 connected in sequence , the second water cooler 8, a resonant tube 11 is arranged between the first loop traveling wave thermoacoustic nuclear feedback tube 1 and the second loop traveling wave thermoacoustic nuclear feedback tube 1, and a power generating device is arranged in the middle of the resonant tube 11. A frequency stabilizing device is provided between the first loop traveling wave thermoacoustic nuclear therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com