Composite damping elastic support

A technology of elastic support and composite damping, which is applied in the direction of spring/shock absorber, shock absorber, mechanical equipment, etc., can solve the problems of not having automatic stiffness change, poor adaptability, self-heavyness, etc., and achieve improved isolation effect, The effect of high structural strength and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

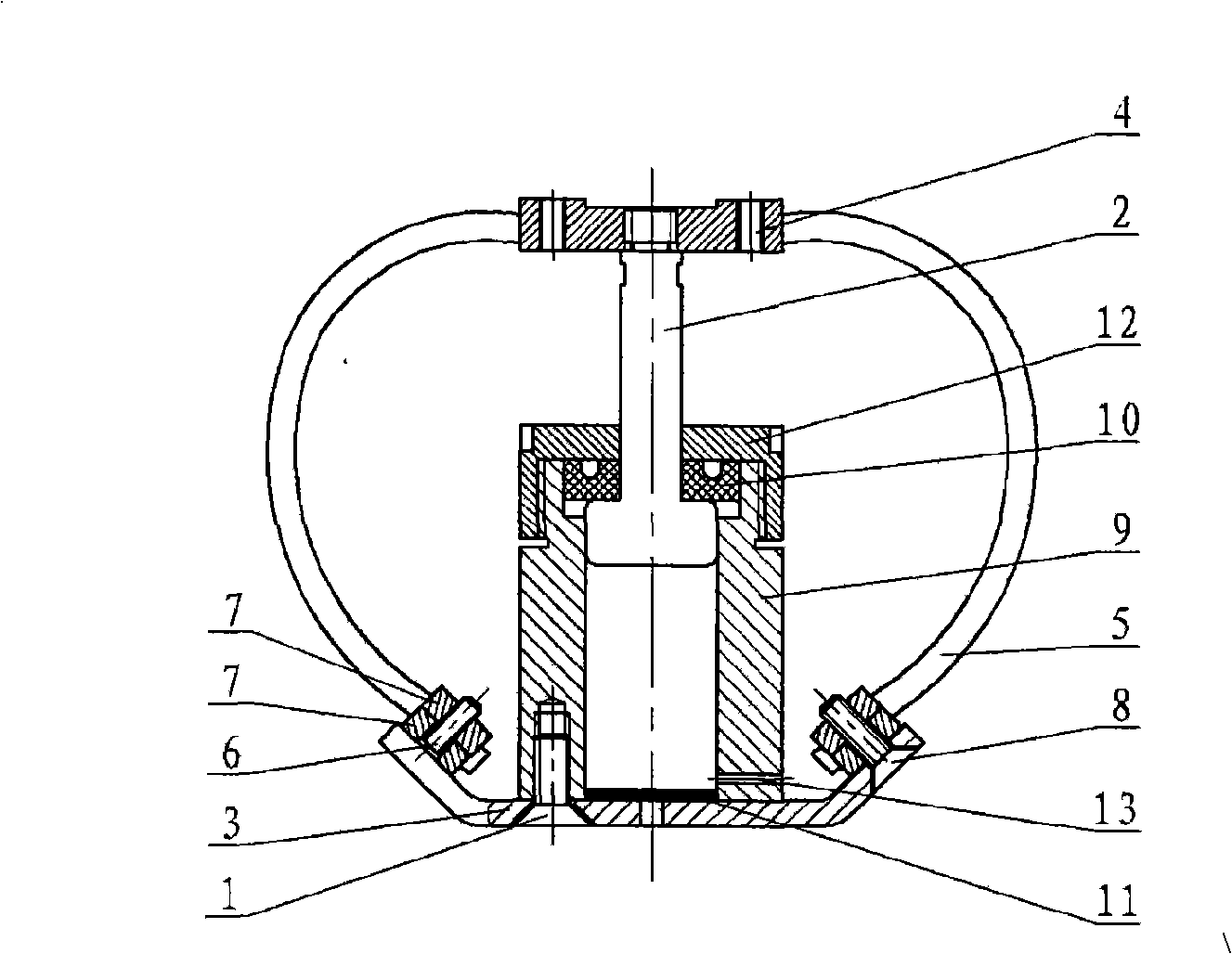

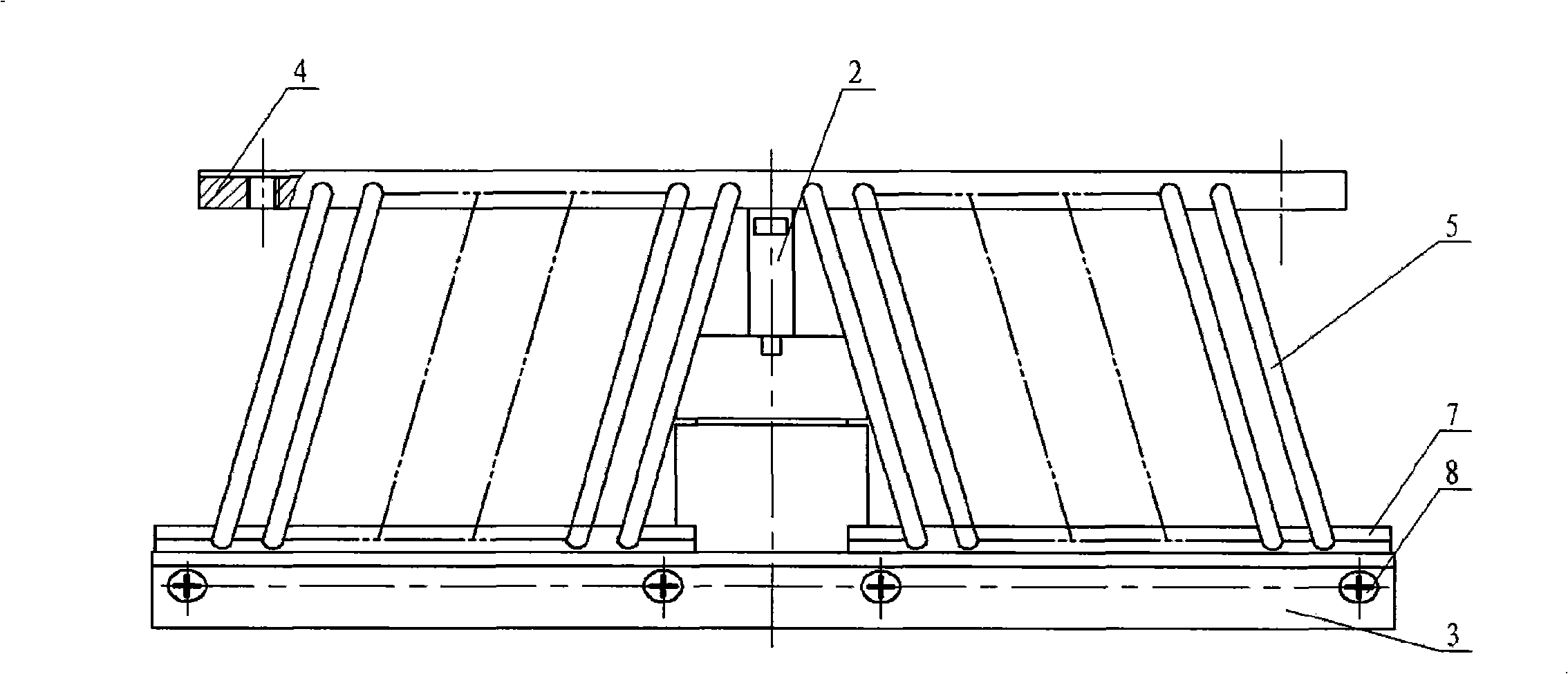

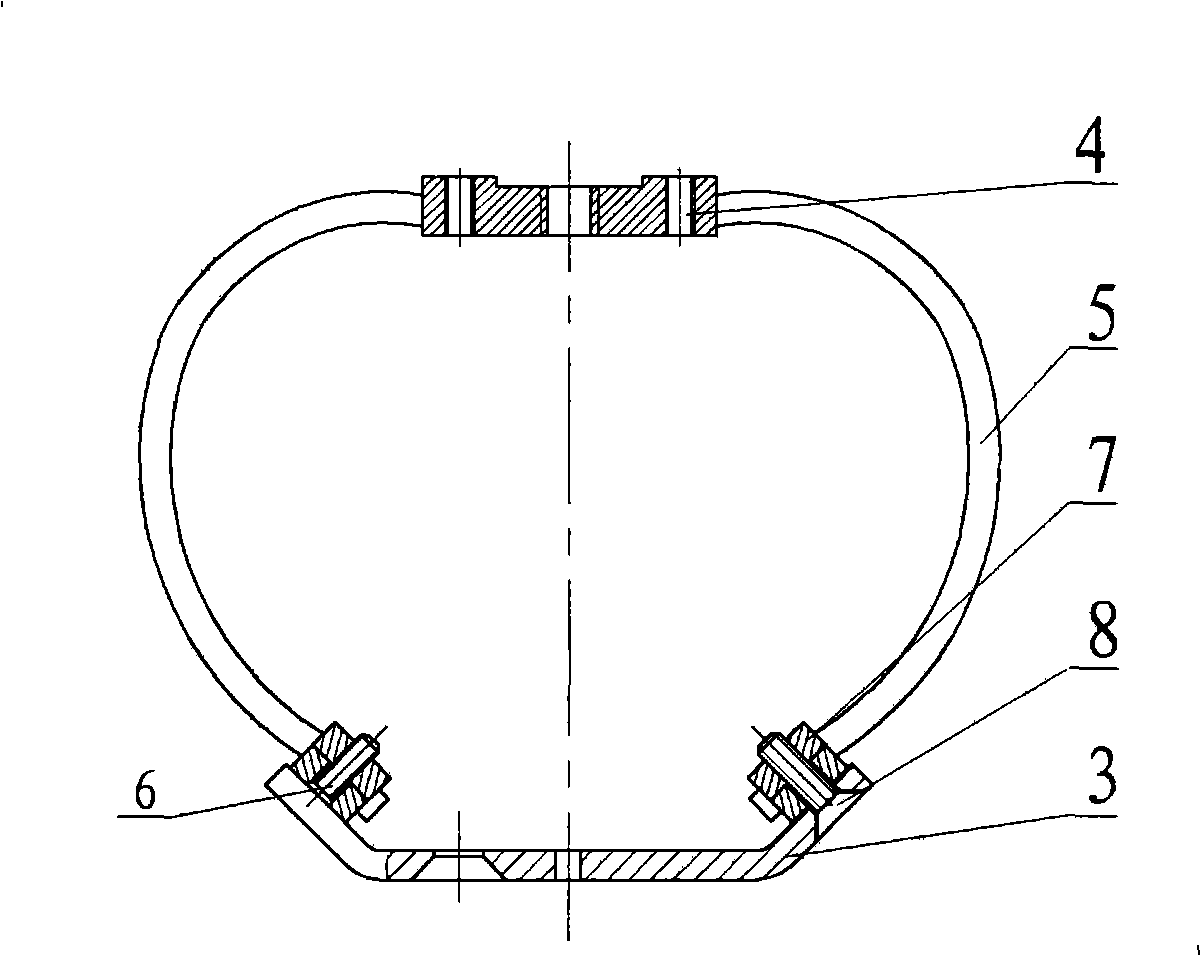

[0022] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0023] as attached figure 1 , attached figure 2 As shown, the present invention is mainly composed of two parts, the annular elastic body and the damping buffer mechanism. The damping buffer mechanism is placed in the middle of the installation bottom plate 3 and the connecting plate 4 of the annular elastic body. The upper end of the damping buffer mechanism is connected with the connecting plate 4 of the annular elastic body through the thread on the piston 2, and the lower end is connected with the ring by screw 1. The mounting base plate 3 of the elastic body is connected to form the whole of the present invention. In engineering application, bolts are used between the installation base plate 3 of the annular elastic body and the foundation, and bolts are also used between the connecting plate 4 and the engineering equipment, so that the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com