Ac motor

An AC motor, alternate ground technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of difficult to form magnetic cores, expensive, poor magnetism and strength, and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the AC motor of the present invention will be described below.

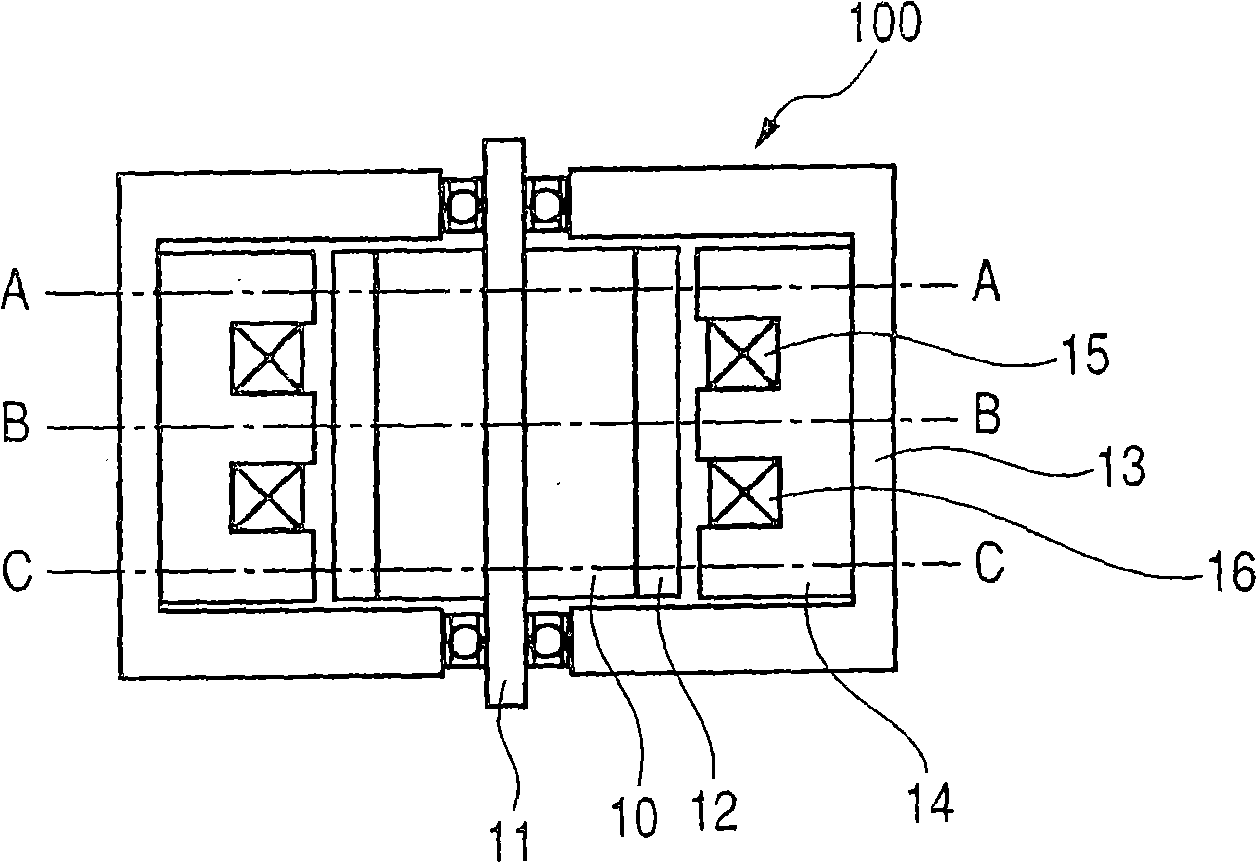

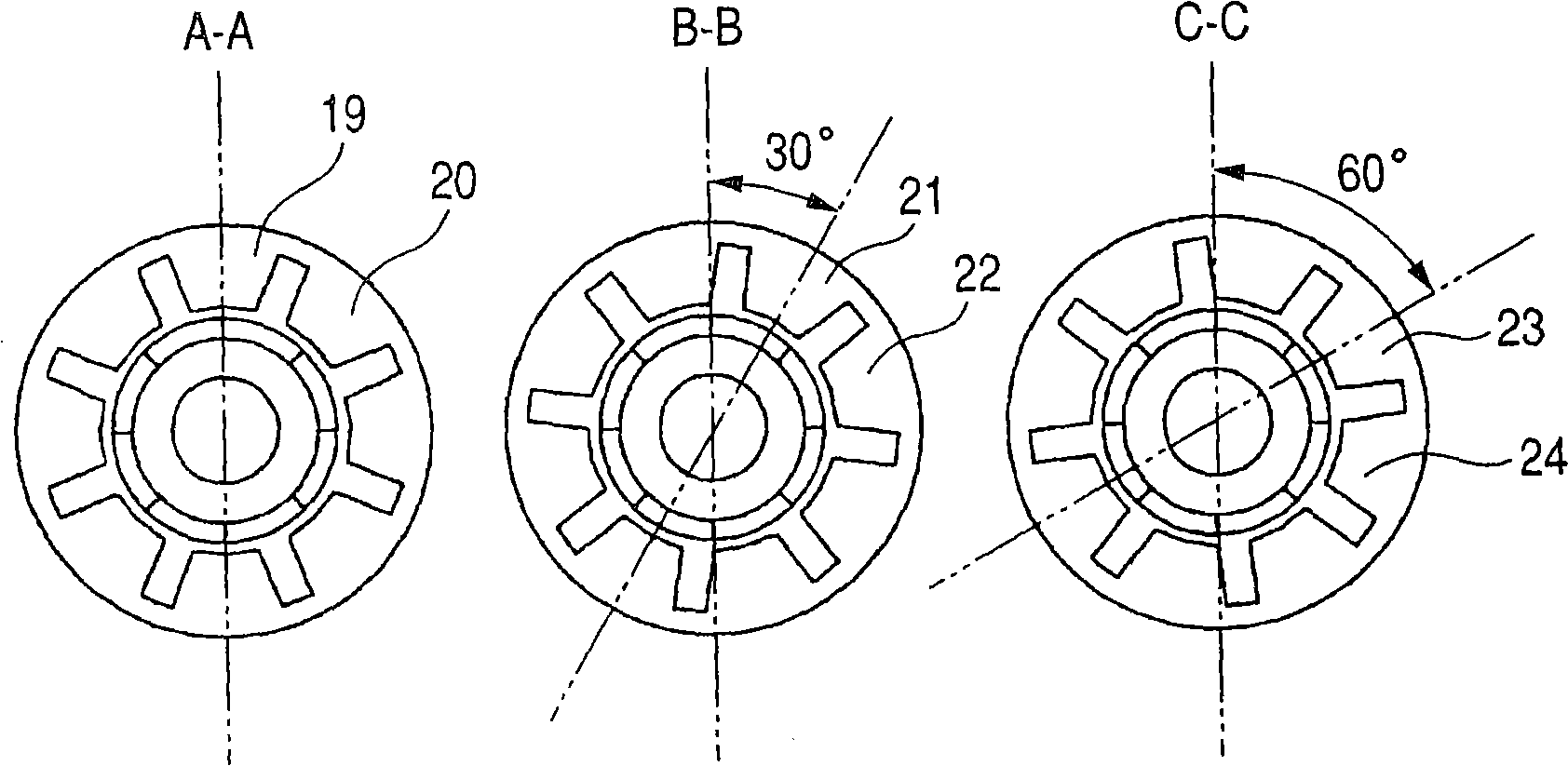

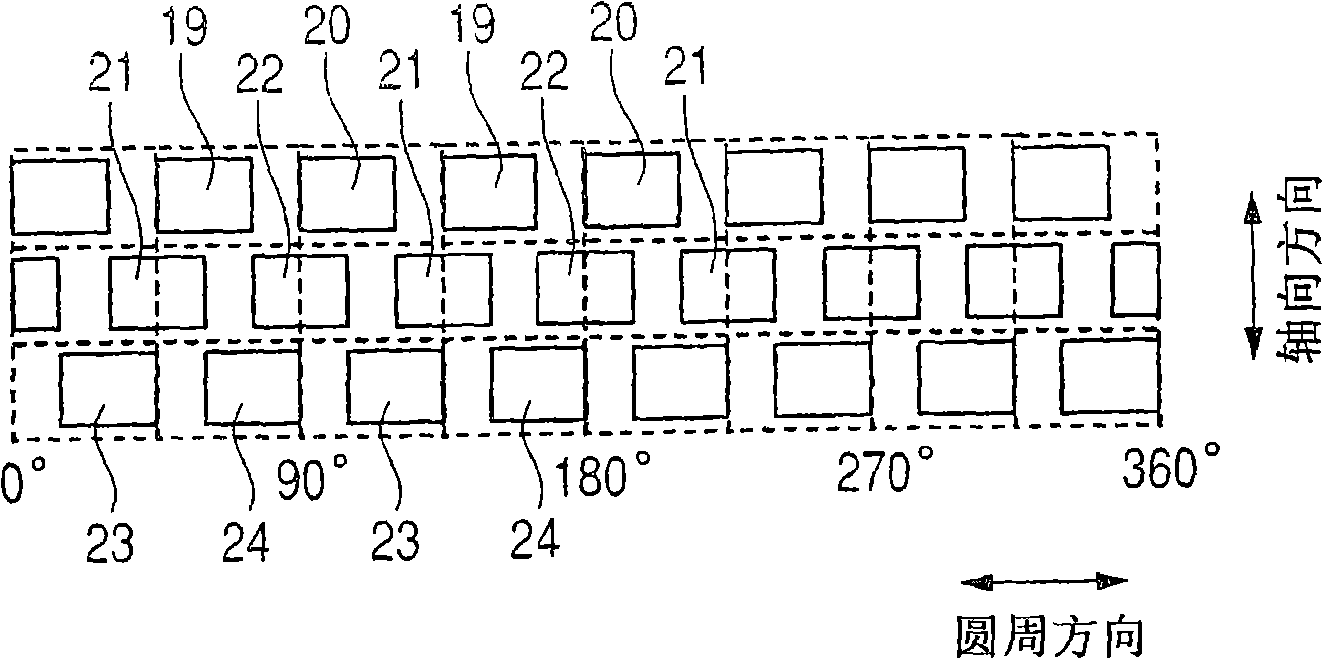

[0057] figure 1 is a schematic axial sectional view of the motor 100 . figure 2 is the display edge figure 1 A-A, B-B, C-C are schematic cross-sectional views of the motor 100 . image 3 is a schematic diagram of the circumferential development of the stator poles of the motor 100 . Figure 4 is a schematic diagram of the circumferential development of the rotor of the motor 100 . Figure 5 It is a schematic diagram of the circular expansion of the ring winding (two phase windings of different phases) of the motor 100 .

[0058] First, the basic structure of the motor 100 will be described.

[0059] The motor 100 includes a rotor 10 fixed to a rotating shaft 11 and having an SPM (surface permanent magnet) structure in which a cylindrical permanent magnet 12 is fixed to the outer periphery of the rotor 10 . The rotary shaft 11 is rotatably supported by the housing 13 through bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com