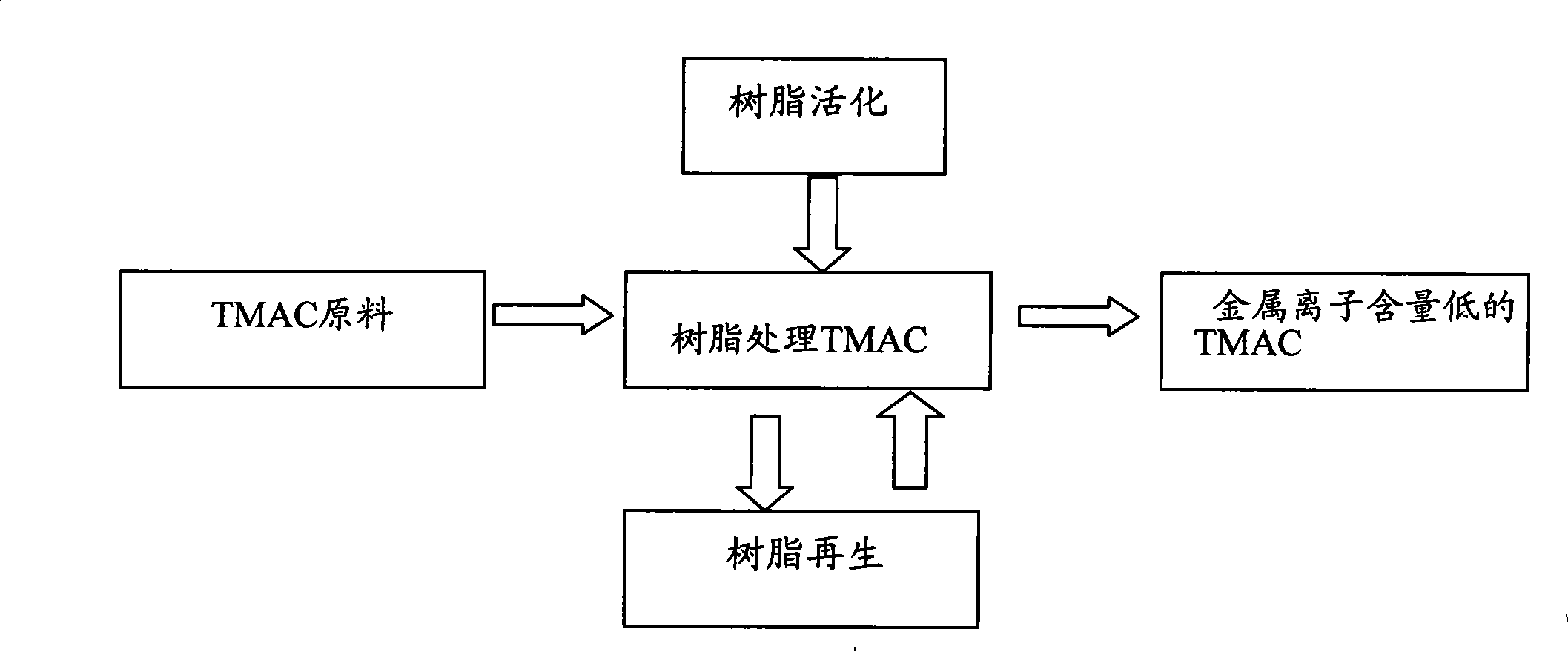

Method for treating tetramethyl ammonium carbonate with ion exchange resin

A technology of tetramethylammonium carbonate and ion exchange resin, which is applied in the field of ion exchange resin treatment of tetramethylammonium carbonate, can solve the problems of unrealistic concentration of metal ions, and achieve the effects of easy regeneration, energy-saving removal, and high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] At a temperature of 40°C, add 20 kg of 50% TMAC to 10 kg of activated C100 resin, and circulate for 2 hours.

[0021] The content of metal ions before treatment (unit: ppb) is: Li<0.05, Na 0.53, Mg 0.38, Al 0.25, K 0.95, Ca 0.72, Cr 61.3, Mn 4.35, Fe 220.5, Ni 38.0, Co 1.07, Cu 1.36, Zn 1.89, Mo 4.98, Cd<0.05, Pb<0.5, Ag 0.07, Ti 0.87;

[0022] The content of metal ions after treatment (unit: ppb) is: Li 0.07, Na 0.5, Mg 0.21, Al 0.44, K 0.9, Ca 0.9, Cr 40.9, Mn 2.35, Fe 180.5, Ni 1.87, Co 1.62, Cu 0.53, Zn 1.92 , Mo 2.21, Cd<0.05, Pb<0.5, Ag 0.05, Ti 0.56.

[0023] Resin regeneration.

Embodiment 2

[0025] At a temperature of 50° C., 20 kg of 50% TMAC was added to 10 kg of activated C100E resin and circulated for 6 hours.

[0026] The content of metal ions before treatment (unit: ppb) is: Li<0.05, Na 0.53, Mg 0.38, Al 0.25, K 0.95, Ca 0.72, Cr 61.3, Mn 4.35, Fe 220.5, Ni 38.0, Co 1.07, Cu 1.36, Zn 1.89, Mo 4.98, Cd<0.05, Pb<0.5, Ag 0.07, Ti 0.87;

[0027] The content of metal ions after treatment (unit: ppb) is: Li<0.05, Na 0.54, Mg 0.16, Al 0.14, K 1.02, Ca 0.32, Cr 50.9, Mn 0.98, Fe 7.8, Ni 1.5, Co 1.45, Cu0.34, Zn 1.87, Mo 2.11, Cd<0.05, Pb<0.5, Ag 0.05, Ti 0.44.

[0028] Resin regeneration.

Embodiment 3

[0030] At a temperature of 65°C, 20kg of TMAC with a concentration of 30% was added to 10kg of activated TP208 resin, and the treatment was circulated for 8 hours.

[0031] The content of metal ions before treatment (unit: ppb) is: Li<0.05, Na 0.53, Mg 0.38, Al 0.25, K 0.95, Ca 0.72, Cr 61.3, Mn 3.35, Fe 165.5, Ni 38.0, Co 0.98, Cu 1.36, Zn 1.89, Mo 2.98, Cd<0.05, Pb<0.5, Ag 0.07, Ti 0.67;

[0032] The content of metal ions after treatment (unit: ppb) is: Li<0.05, Na 0.54, Mg 0.18, Al 0.11, K 1.02, Ca 0.32, Cr 40.9, Mn 0.98, Fe 117.8, Ni 1.5, Co 1.45, Cu 0.34, Zn 1.27, Mo 2.11, Cd<0.05, Pb<0.5, Ag 0.05, Ti 0.34.

[0033] Resin regeneration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com