Drying system for aqueous materials

A technology for the treated object and drying system, which is applied in the direction of drying solid materials, solid waste removal, heating to dry solid materials, etc. It can solve the problems of odor and odor around, and achieve easy drying control and stable temperature , Efficient drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

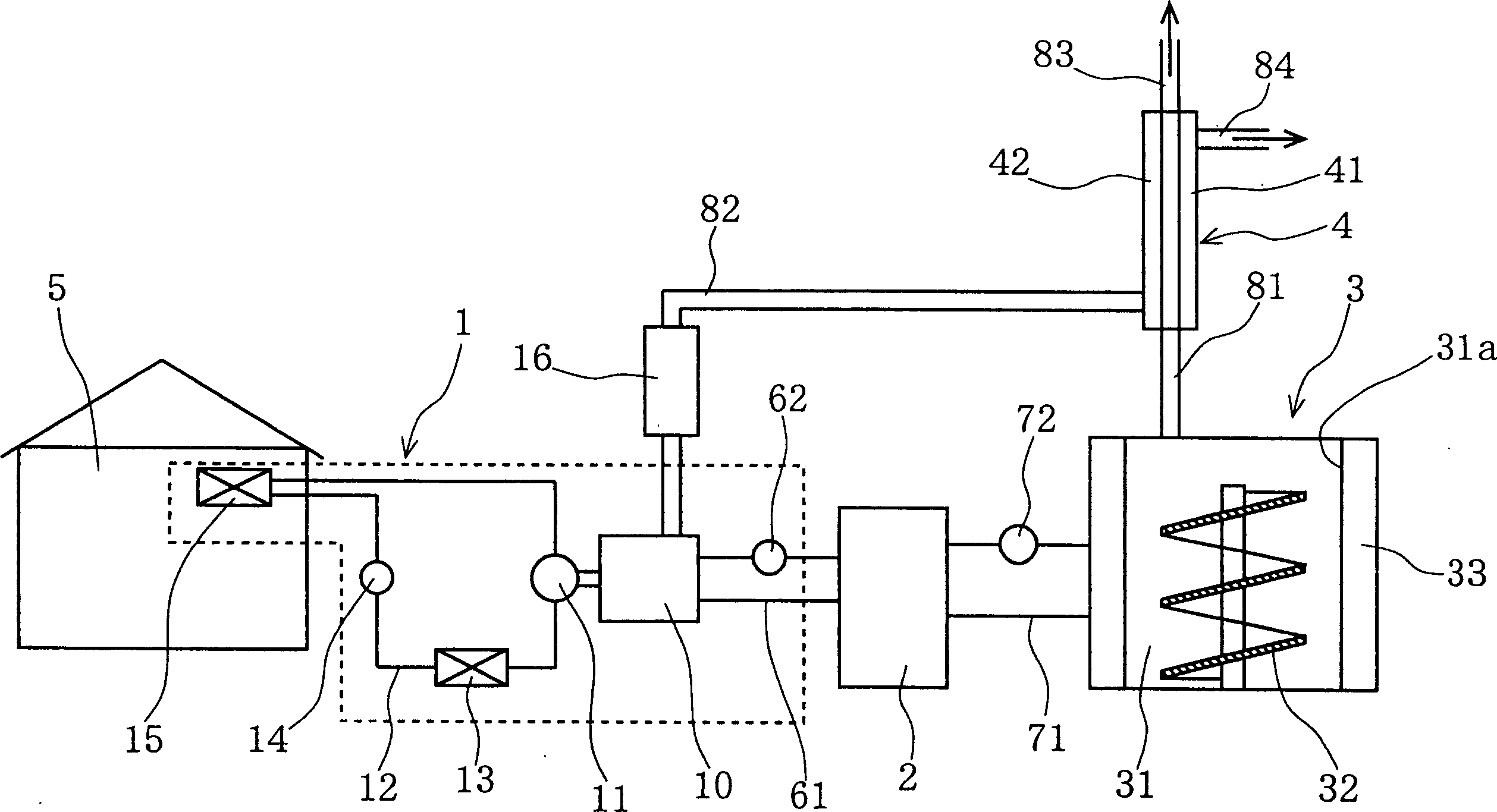

[0018] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is an explanatory drawing explaining the drying system of the aqueous to-be-processed object which concerns on embodiment. The drying system for the aqueous treated object is composed of an engine-driven air conditioner 1 , a water storage tank 2 , a vacuum dryer 3 and a deodorizing device 4 . The engine-driven air conditioner 1 uses the engine 10 to rotate the coolant compressor 11 to circulate the coolant in the coolant circuit 12 .

[0019] During cooling, the coolant circulates in the coolant circuit 12 in the order of the outdoor heat exchanger 13 , the expansion valve 14 , and the indoor heat exchanger 15 installed indoors. At this time, heat is released in the outdoor heat exchanger 13 and absorbed in the indoor heat exchanger 15 . On the other hand, during heating, the coolant circuit 12 circulates in the order of the indoor heat exchanger 15 , the expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com