High power LED phase transition heat sink structure

A high-power, phase-change heat technology, applied to semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve problems such as heat dissipation, achieve the effect of improving heat dissipation, reducing temperature difference, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

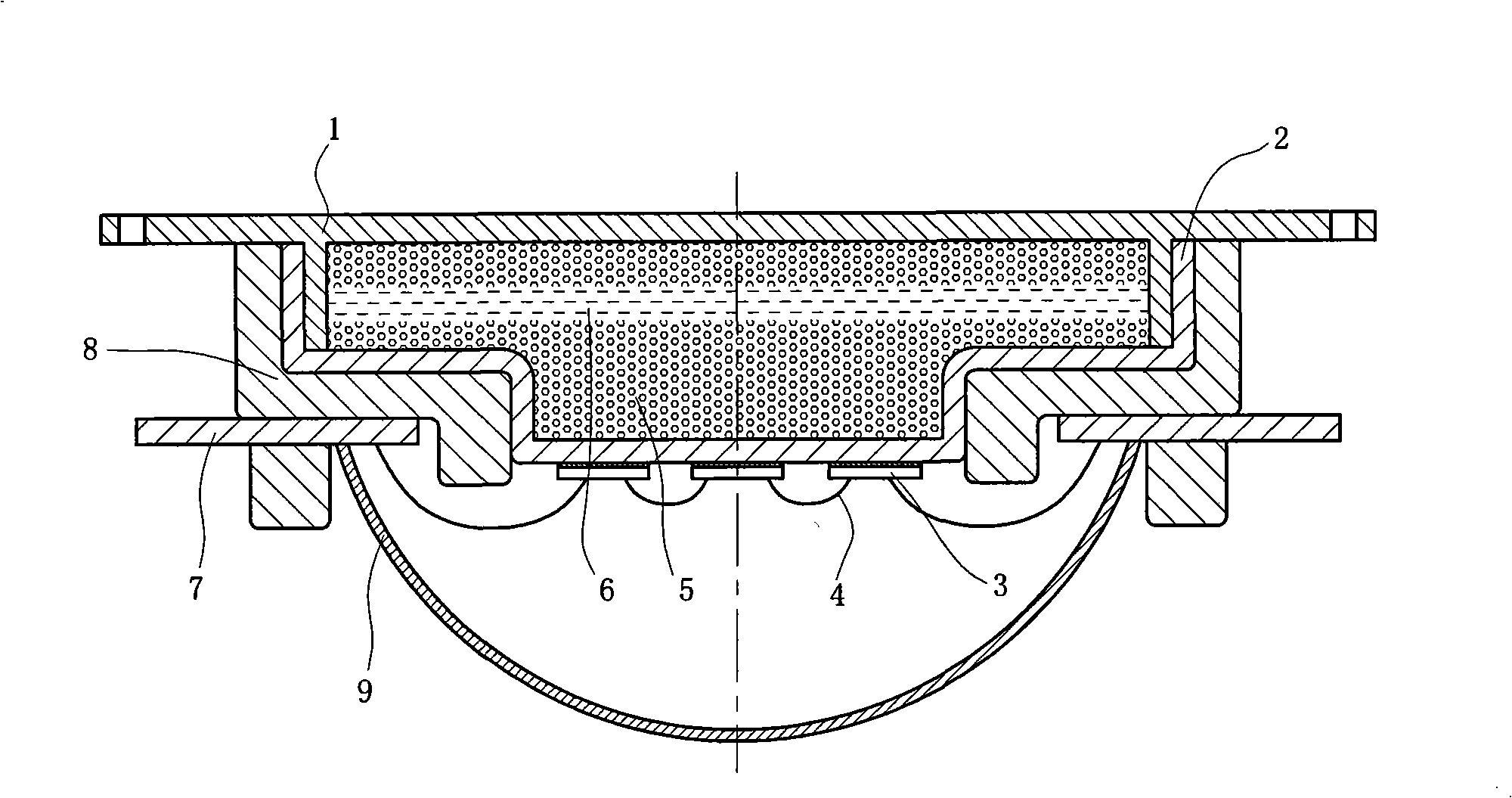

[0028] Such as figure 1 , 2 As shown, the phase change heat sink and packaging structure of a high-power LED includes a sealing end cover 1, a heat sink body 2, a high-power LED chip 3, a gold wire 4, a boiling structure 5, a working medium 6, and an electrode 7 And the lens 9, the sealing end cap and the heat sink body are circular structures with cavities, which are closely connected by welding or cementing to form a closed cavity, which is sealed into a vacuum state, and has a boiling structure 5 and low temperature in the cavity. Boiling heat transfer working medium 6; the sealing end cover 1 and the LED mounting aluminum substrate can be connected together by screws; the outside of the lower end of the heat sink body 2 and the outside of the sealing end cover 1 are both planar structures. The boiling structure 5 is in the form of copper powder sintering. First put the copper powder into the cavity of the sealing end cover 1 and the heat sink body 2, reserve 10% of the ca...

Embodiment 2

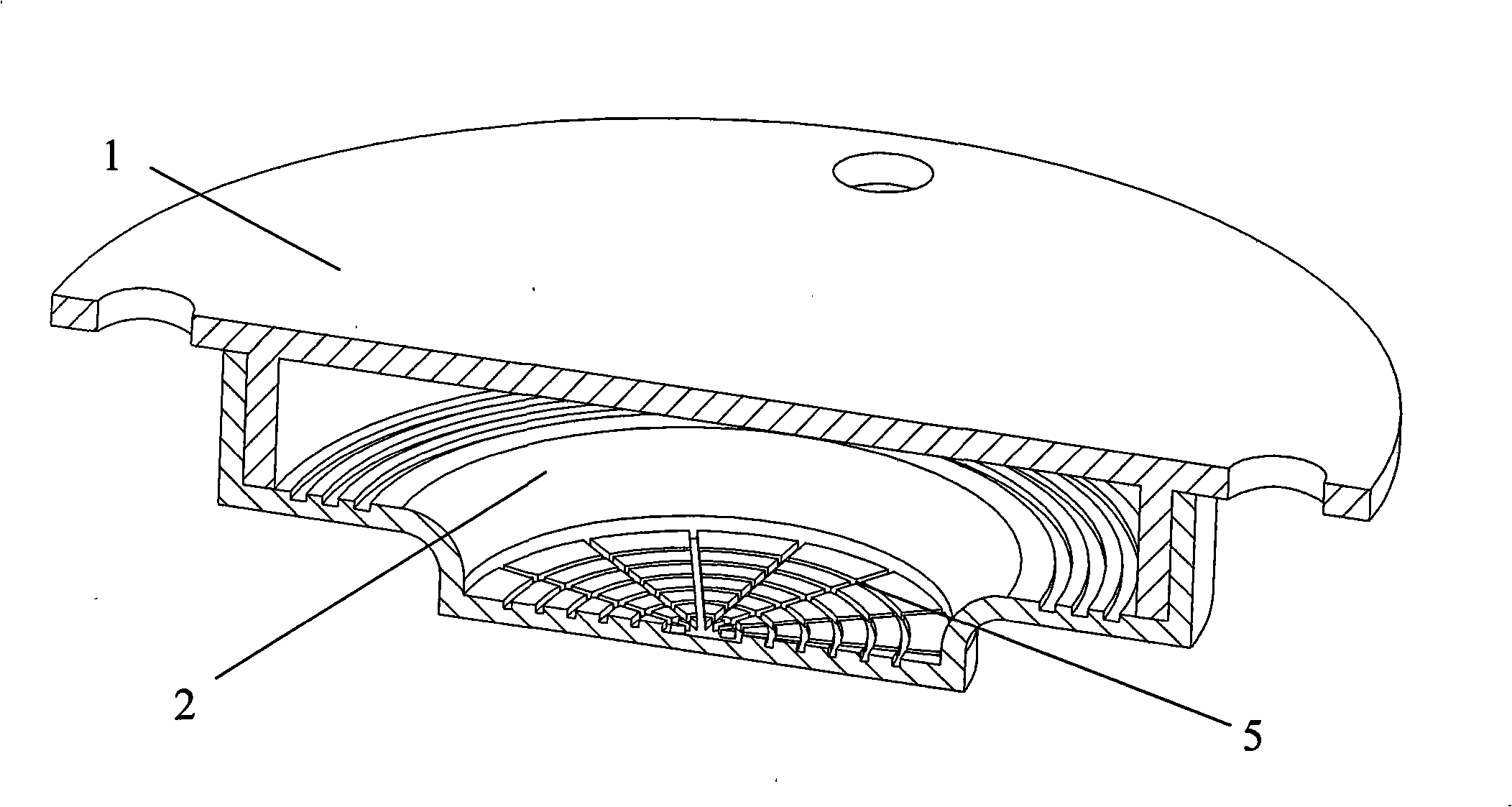

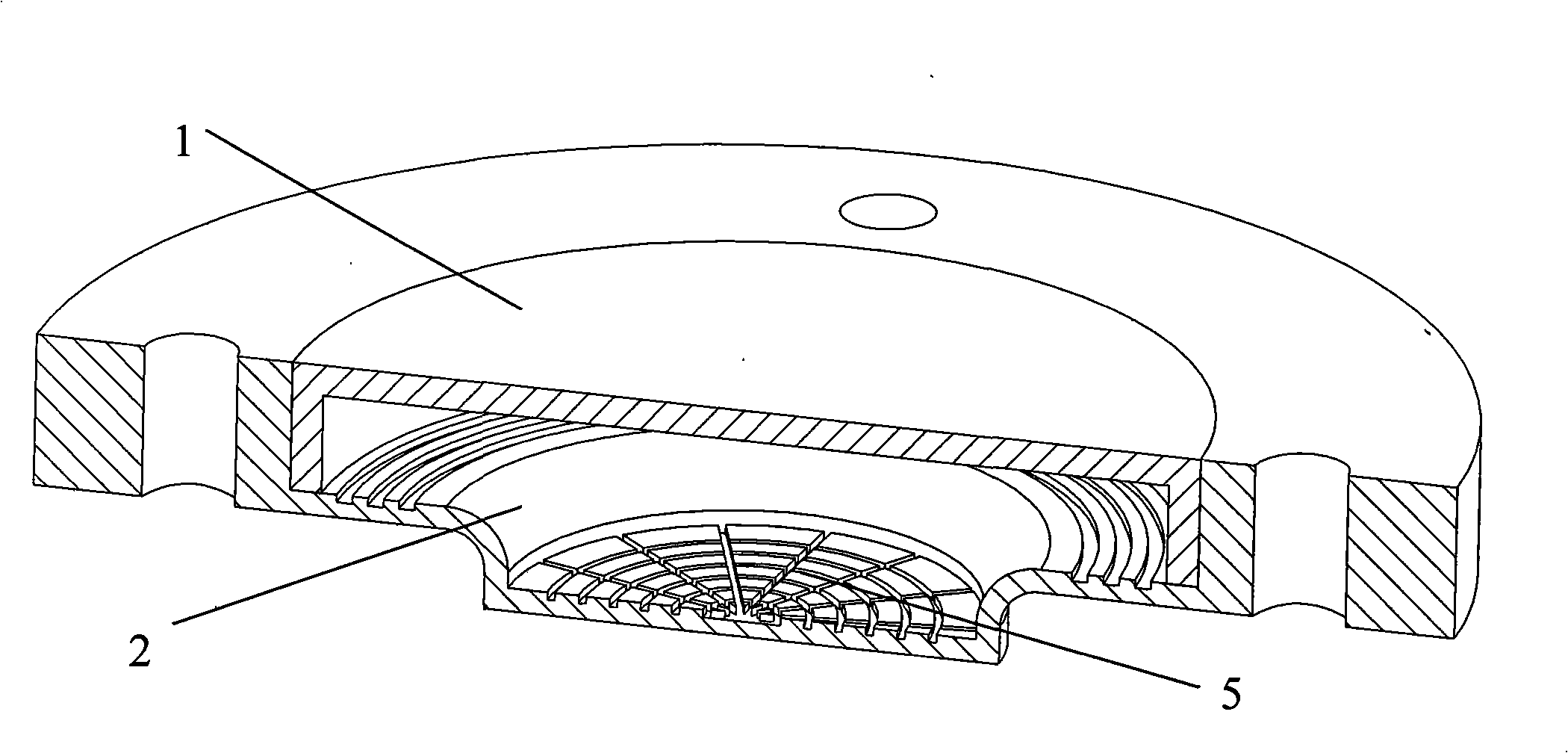

[0030] Such as image 3 As shown, a high-power LED phase-change heat sink and sealing end cap 1 of the packaging structure adopts a circular structure, is placed in the heat sink body 2, and is connected with the heat sink body 2 by welding or gluing. The heat sink body 2 and the LED mounting aluminum substrate can be connected together by screws; the lower end of the heat sink body 2 adopts a circular structure, and the boiling structure 5 is made of porous material sintered. The porous material is commercial foam copper or aluminum foam. The sintering method Same as copper powder sintering. The low temperature boiling heat transfer working medium 6 is acetone. Such as Figure 5b As shown, the high-power LED chips 3 are arranged in a circle, and are fixed on the lower end of the heat sink body 2 by welding in parallel or in series. Others are with embodiment 1.

Embodiment 3

[0032] Such as Figure 4 As shown, a high-power LED phase-change heat sink and sealing end cap 1 of the packaging structure adopts a square structure, is placed in the heat sink body 2, and is connected with the heat sink body 2 by welding or bonding, and the heat sink body 2 is connected together. The sink body 2 and the LED mounting aluminum substrate can be connected together by screws; the lower end of the heat sink body 2 adopts a square structure, and the boiling structure is in the form of square grooves, and the grooves are processed by ordinary machine tools at the lower end of the cavity. The high-power LED chip 3 is one piece, which is fixed on the lower end of the heat sink body 2 by welding, and the low-temperature boiling heat transfer medium 6 is ethanol; the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com